As the modern manufacturing industry continues to raise demands for precision and efficiency in complex component production, multi-axis synchronized CNC technology is reshaping the production paradigm in the precision machining field, leveraging its multi-dimensional coordinated motion control logic. Starting from core principles, this article systematically breaks down the process innovations of 5-axis simultaneous cutting and explores the mechanism by which expanding the number of synchronized axes enhances the machining precision of complex curved surfaces. By comparing traditional machining modes, it focuses on analyzing how multi-axis synchronization optimizes production processes by reducing the number of repeated clamping operations. Combined with typical scenarios such as aerospace engine blades and orthopedic implants, it elaborates on the groundbreaking applications of this technology in manufacturing high-difficulty structural components. Subsequent sections will delve into technical details and industry practices, demonstrating how flexible production systems drive the evolution of precision manufacturing standards.

Analysis of Core Multi-Axis Synchronization Technology

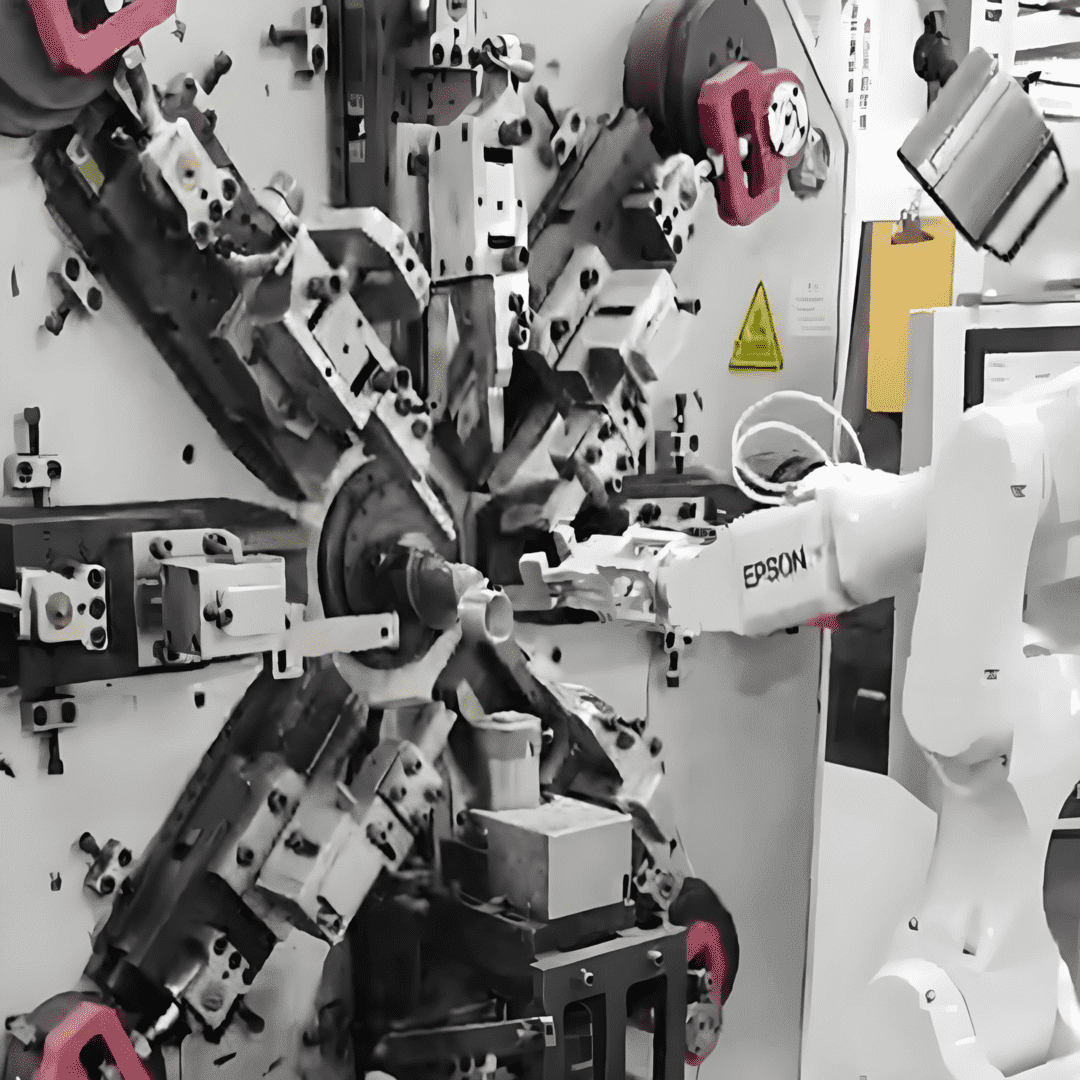

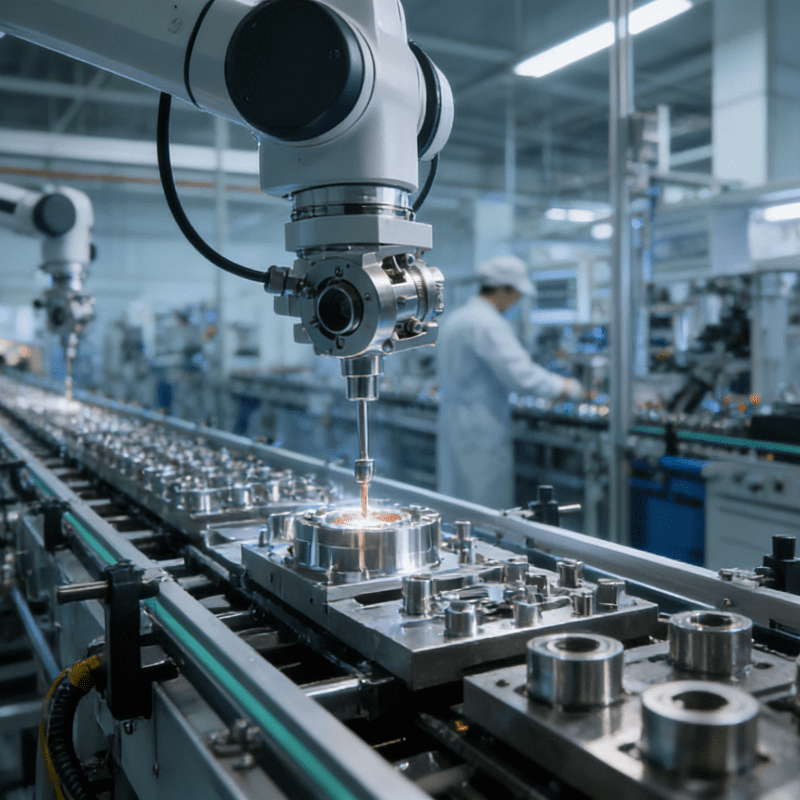

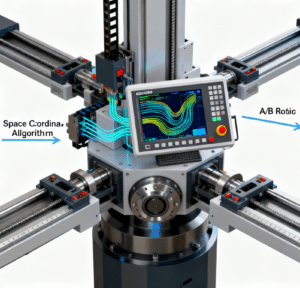

The technical core of multi-axis synchronized CNC machining lies in high-precision dynamic control under the coordinated motion of multiple axes. Traditional 3-axis machine tools can only perform cutting along the linear X/Y/Z directions, while multi-axis synchronized technology adds rotational axes (e.g., A-axis, B-axis, C-axis) to enable synchronized motion between the tool and the workpiece across 5 degrees of freedom. Its essence lies in the real-time calculation and compensation of multi-axis trajectories by the CNC system: complex curved surface machining paths are decomposed into synchronized commands for each axis through spatial coordinate transformation algorithms, ensuring the tool always contacts the workpiece surface at the optimal angle. Taking impellers and aerospace engine blades as examples, 5-axis synchronized technology can complete precision milling of spiral grooves and curved contours in one operation, avoiding cumulative errors caused by repeated clamping. Additionally, the application of dynamic tool radius compensation and thermal deformation correction modules further controls machining precision at the micron level, laying a foundation for the efficient forming of special-shaped structures.

Process Innovation in 5-Axis Simultaneous Cutting

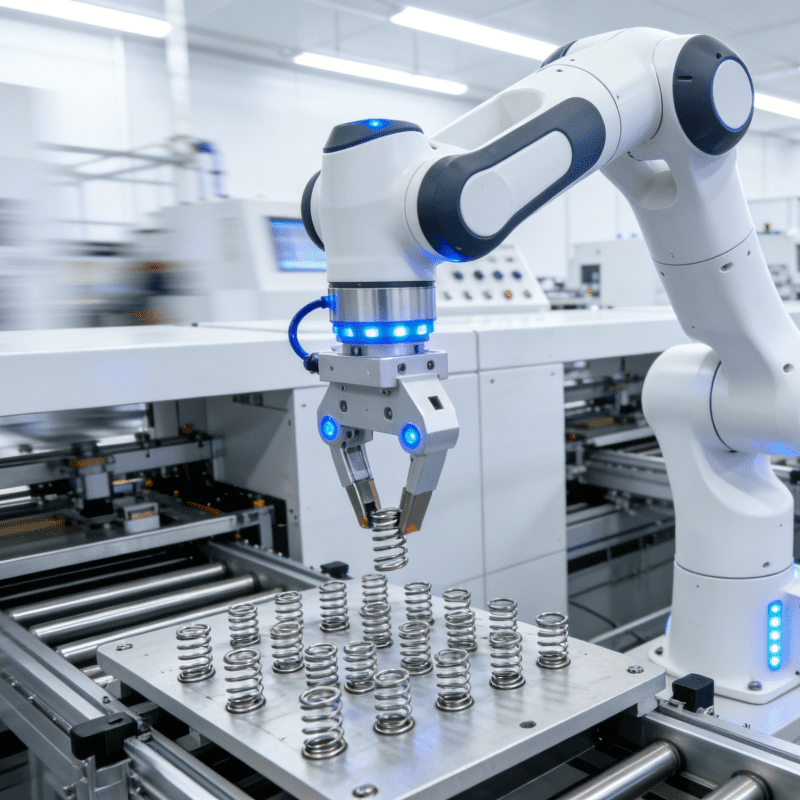

5-axis synchronized CNC technology achieves multi-dimensional spatial trajectory control of tools and workpieces through the dynamic coordination of linear X/Y/Z axes and two rotational axes. Compared with the limitation of traditional 3-axis machine tools, which require repeated adjustments of clamping angles, 5-axis simultaneous cutting allows the tool to operate continuously along the optimal feed path. A single clamping operation can complete the full-process machining of special-shaped structures such as prisms and impellers. Taking the machining of aerospace engine turbine blades as an example, the synchronization of the rotating worktable and the swiveling head ensures that the ball-end mill maintains vertical contact with the complex curved surface at all times—this not only shortens the machining cycle by 40% but also stabilizes the contour precision within ±0.01mm. This process breakthrough significantly reduces cumulative errors caused by repeated positioning. In the precision milling of artificial joints in the medical device field, 5-axis synchronization technology optimizes the surface roughness to Ra 0.4μm, meeting the strict machining requirements for biocompatible materials.

Precision Breakthroughs in Complex Curved Surface Machining

Unlike the layered cutting mode of traditional 3-axis machine tools for complex curved surfaces, multi-axis synchronized CNC technology achieves dynamic spatial matching between the tool and the workpiece through 5-axis synchronized control. When machining components with free-form surfaces (e.g., turbine blades, artificial joints), the system can adjust the tool’s attitude angle and feed path in real time, ensuring the cutting point is always perpendicular to the normal direction of the curved surface and controlling the contour error within ±0.005mm. This groundbreaking process not only avoids datum deviation caused by repeated clamping but also stabilizes the surface roughness Ra value below 0.4μm through an adaptive thermal deformation compensation algorithm. For instance, in the machining of aerospace engine impellers, multi-axis simultaneous cutting improves the blade profile precision by 60% while reducing the man-hours required for subsequent polishing processes by 75%, significantly enhancing the functionality and reliability of complex curved surface components.

Application Cases of Efficient Flexible Production

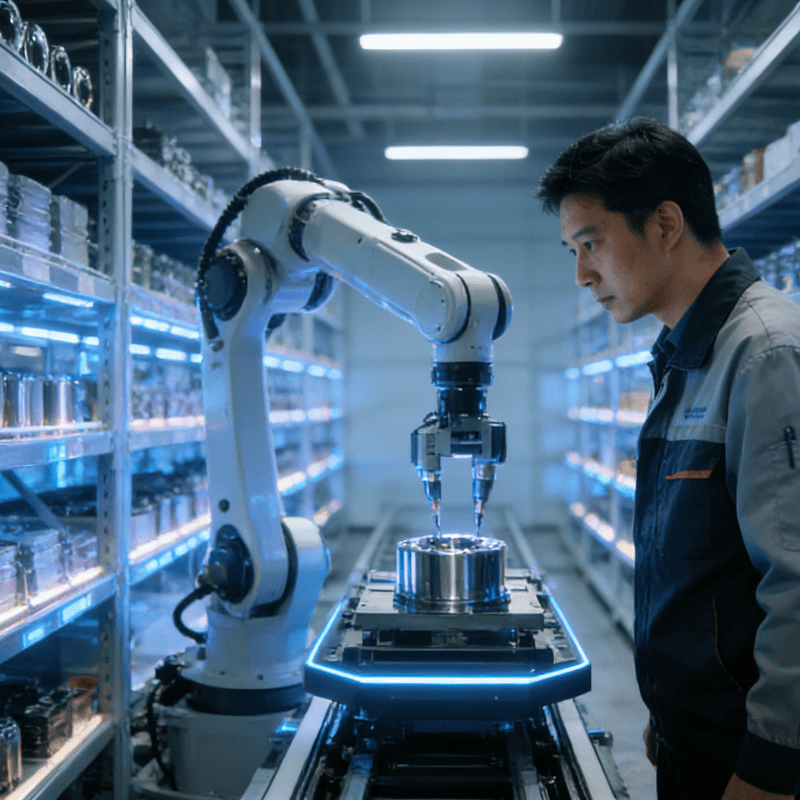

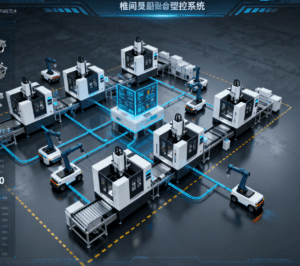

Taking the manufacturing of typical turbine blades in the aerospace field as an example, 5-axis synchronized CNC systems achieve continuous machining of twisted blade surfaces and special-shaped tenon grooves through dynamic tool axis vector control. The original process for a certain type of blade required 12 clamping and positioning operations; after adopting multi-axis synchronization technology, this was reduced to a single complete machining process, with surface roughness stably controlled within Ra 0.4μm and the single-piece production cycle shortened by 78%. In medical device manufacturing, the machining of porous structures in orthopedic implants also benefits from multi-axis synchronization technology. A certain type of titanium alloy intervertebral fusion cage uses a 4-axis synchronized milling process, achieving a forming precision of ±0.005mm for 132 gradient pore size structures while supporting rapid product changeover for 15 specifications. Notably, an automotive component enterprise integrated multi-axis machining centers with intelligent fixture systems and Flexible automatic loading and unloading vibrators to build a flexible production line covering 23 types of products (including engine blocks and transmission housings)—the vibrator realizes automatic sorting, orientation and feeding of blank workpieces with different specifications, matching the rapid tool change and machining rhythm of multi-axis equipment, which together increase equipment utilization to 92% and reduce the daily mold change frequency by 40%.

Looking at the current trends in manufacturing transformation, multi-axis synchronized CNC technology is reconstructing the underlying logic of complex component production by breaking the spatial limitations of traditional machining. Its core value lies not only in the expanded geometric degrees of freedom brought by 5-axis synchronized motion but also in integrating the design, machining, and inspection links into a coherent digital closed loop. From ensuring micron-level precision for turbine blades in the aerospace field to optimizing the biocompatibility of complex curved surfaces in medical implants, this technology significantly improves the predictability of manufacturing systems by reducing manual intervention and process connection errors. With the continuous evolution of intelligent compensation algorithms and adaptive tool path planning, multi-axis synchronization technology is shifting from the upgrading of single-equipment capabilities to systematic breakthroughs in full-process production efficiency, opening up broader space for process innovation in the precision manufacturing field.