The modern manufacturing industry has an increasingly urgent demand for high-efficiency and precision machining of complex components. Although traditional 5-axis machining technology is mature, there is still room for improvement in overcoming efficiency bottlenecks. This paper focuses on how multi-axis machining systems break through the linkage limitations of traditional 5-axis machine tools through innovative collaborative cutting strategies. We will delve into the technical principles of multi-spindle synchronous operation and analyze its significant speed advantages in processing complex curved surfaces. Through practical application cases such as key auto parts and precision aerospace structural components, we will specifically demonstrate the contribution of multi-axis configuration to the overall production capacity improvement. The core is to reveal how multi-axis collaborative machining provides a feasible efficiency upgrading path for component manufacturers pursuing both high precision and high efficiency.

Multi-Axis Machining Outperforms 5-Axis in Efficiency

When it comes to high-end machining, many people first think of 5-axis machine tools. It is true that 5-axis machining is highly capable of handling complex curved surfaces. However, simply in terms of the number of spindles, multi-axis systems often achieve more significant breakthroughs in improving overall production efficiency through ingenious collaborative operation modes. The key lies in that the core advantage of multi-axis configuration is the ability of multiple spindles to participate in cutting simultaneously. Imagine multiple spindles on a single piece of equipment working collaboratively like a team, processing multiple identical or similar components at the same time, or machining multiple different areas of a single component. This directly reduces equipment waiting, tool changing and workpiece clamping time, greatly shortening the total processing cycle of a single component. In contrast, even top-tier 5-axis machine tools, although capable of linkage machining at complex angles, are limited to single-spindle operation at any given time. In scenarios requiring mass production, their output efficiency per unit time may be surpassed by multi-axis systems with multi-spindle collaborative capabilities. This efficiency advantage is particularly prominent in fields such as auto parts manufacturing that demand high-volume and high-consistency production.

Collaborative Cutting Overcomes Efficiency Bottlenecks

The core advantage of multi-spindle collaborative cutting is that it can break through the inevitable efficiency bottlenecks in traditional 5-axis machining. Although 5-axis machine tools are flexible and capable of processing complex curved surfaces, they usually have only one spindle performing cutting operations, and their machining efficiency is limited by the metal removal capacity of a single spindle. On the contrary, multi-axis systems are equipped with multiple independent or semi-independent spindles that can work collaboratively around the workpiece. Imagine multiple cutting tools machining the same complex component at different positions simultaneously, just like a precision machining team conducting coordinated operations. This parallel machining method significantly improves the material removal rate. Especially for complex components with multiple machining surfaces, multi-axis systems can effectively reduce tool waiting time and avoid non-cutting travel caused by frequent changes of machining positions and angles in traditional 5-axis machining. Through carefully planned tool paths, multiple spindles can contact the workpiece at the same time to achieve true “multi-tool simultaneous cutting”, thus greatly compressing the overall machining cycle.

Advantages in Machining Complex Curved Surfaces

For components with extremely complex shapes such as turbine blades and precision molds, traditional 5-axis machining can complete the task, but often encounters efficiency bottlenecks. In comparison, multi-axis collaborative machining systems demonstrate significant advantages. The key is their ability to mobilize multiple spindles for simultaneous operation. Imagine that while a 5-axis machine tool is still coordinating a single spindle to complete complex linkage movements, a multi-axis system already has several tools cutting the same workpiece at different angles and positions simultaneously. This “multi-line operation” capability is particularly effective when machining complex curved surfaces with high distortion and multiple turning angles. It greatly reduces the number of workpiece clamping operations, avoids cumulative errors caused by multiple positioning processes, and thus not only improves machining precision but also significantly shortens the overall machining time. High-precision curved components such as aero-engine blades are typical application scenarios where multi-axis collaborative cutting exerts its speed advantages.

Case Analysis in Automobile, Aerospace and Intelligent Assembly Industries

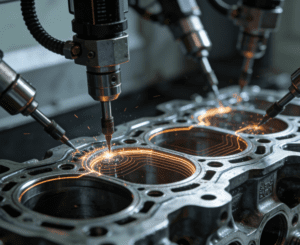

In automobile manufacturing, multi-axis machining systems have significantly improved the efficiency of machining complex curved components through collaborative cutting. For example, when machining automobile engine cylinder blocks, traditional 5-axis machine tools are subject to linkage limitations, with a single piece taking several hours to process; while multi-spindle synchronous cutting technology can machine multiple surfaces simultaneously, increasing efficiency by more than 40% and shortening the production cycle. Similarly, in the aerospace field, the precision machining of aircraft turbine blades has strict high-precision requirements. Multi-axis configuration enables high-speed cutting, reduces process switching time, and significantly improves production capacity. These practical cases demonstrate the speed advantages of multi-axis collaboration in processing complex curved surfaces.

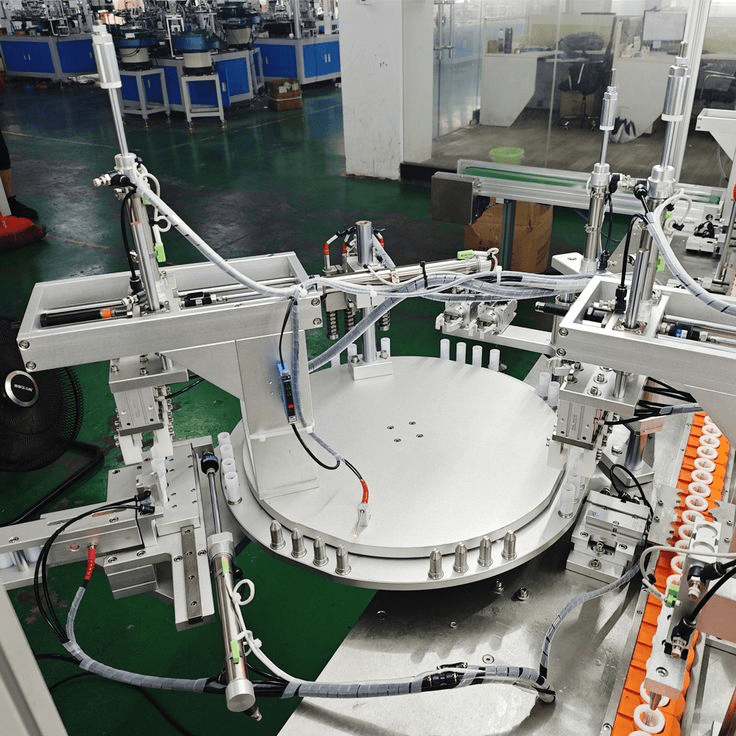

Notably, the multi-spindle collaborative logic has also been successfully applied to intelligent assembly equipment, such as the Contactor Assembly Machine widely used in electrical manufacturing. Contactors require high-precision assembly of coils, contacts, shells and other components, and traditional single-spindle assembly machines are restricted by sequential operation, resulting in long cycle times and high alignment error rates. By adopting a multi-axis collaborative configuration inspired by multi-axis machining, the Contactor Assembly Machine can realize parallel operation of 4-6 assembly spindles—simultaneously completing coil winding, contact riveting and shell fastening at different stations. This collaborative mode reduces the single-piece assembly cycle from 80 seconds to 35 seconds, improves the component alignment precision to ±0.03mm, and lowers the defect rate by over 25%, fully verifying the cross-scenario value of multi-axis collaborative technology.

In practical cases in the auto parts, aerospace and electrical assembly industries, multi-axis machining systems and their derived collaborative technologies have significantly surpassed the efficiency bottlenecks of traditional single-spindle equipment. Multi-spindle synchronous operation solves the limitations of traditional single-station operation, achieving substantial improvements in both processing and assembly efficiency. This not only optimizes overall production capacity but also provides a feasible efficiency upgrading path for manufacturers pursuing both high precision and high efficiency.