Modeling and Simulation of Flexible Manufacturing Systems — A Core Pillar of Industry 4.0

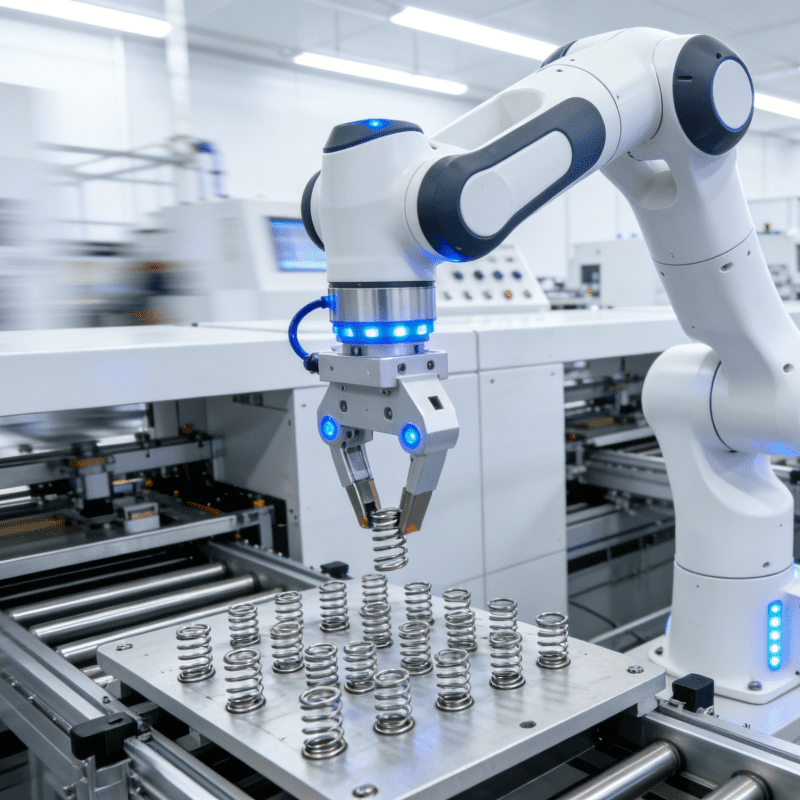

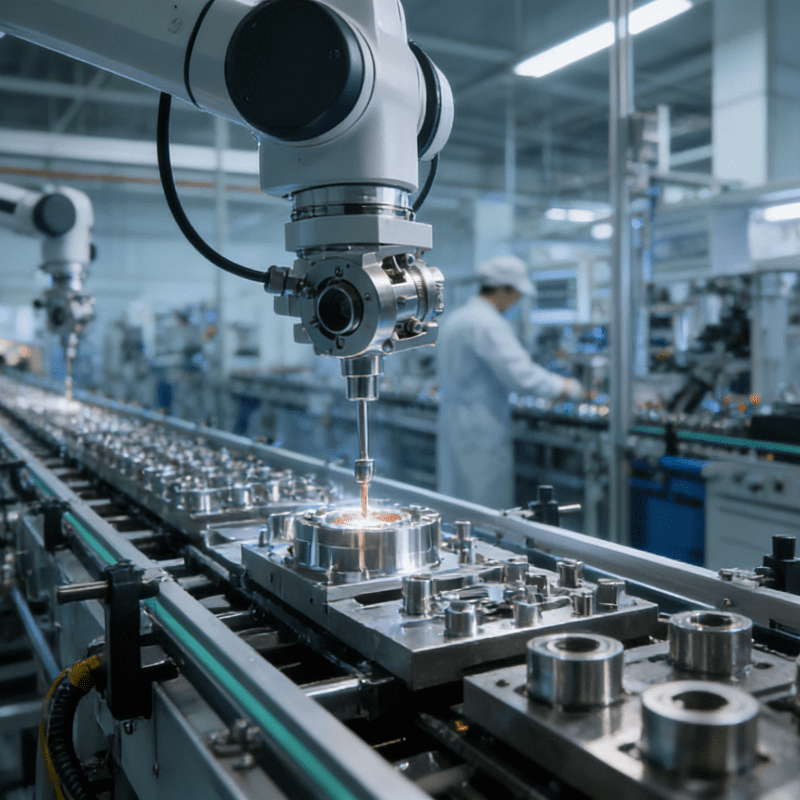

In the era of Industry 4.0, where (intelligent manufacturing) is reshaping global production paradigms, Flexible Manufacturing Systems (FMS) have transcended their role as auxiliary links in traditional manufacturing to become the digital nerve center of smart factories. As market demands grow increasingly personalized and diverse, manufacturers face unprecedented challenges in adapting to dynamic production environments, rapid market fluctuations, and complex optimization of multi-variety, small-batch production. Modeling and simulation technologies, which enable FMS to achieve precise prediction, dynamic adjustment, and iterative optimization, have emerged as the core enablers — empowering FMS to evolve into a strategic cornerstone for enterprises navigating the revolution. This paper proposes an innovative material flow design methodology for FMS, aiming to unlock the full potential of production architectures through systematic modeling and simulation. By bridging virtual and physical manufacturing worlds, it seeks to provide actionable solutions for efficiency improvement and intelligent upgrading of manufacturing processes.

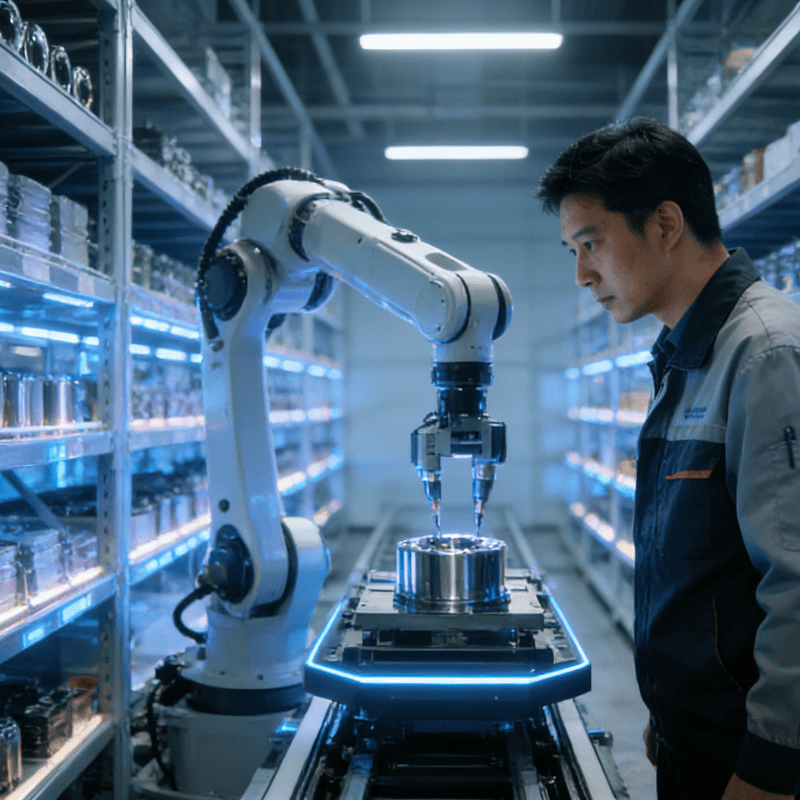

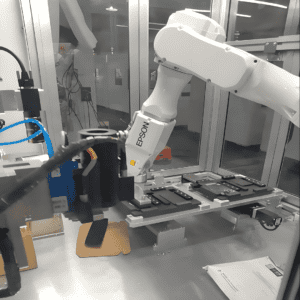

The research leverages specialized simulation software to construct a digital twin model of flexible manufacturing systems, enabling accurate quantification of both technical parameters (e.g., equipment utilization, production takt time) and economic indicators (e.g., cost-efficiency, investment payback ) across all processing and transportation units. Through virtual scenario simulation, the team tests diverse production configurations, compares system performance under varying parameters, and realizes dynamic optimization of production flows — directly enhancing equipment utilization and overall throughput. Building on this foundation, the research has developed an interactive decision-support tool that equips industrial enterprises with capabilities for production line design, operational management, and performance forecasting. This tool facilitates rapid iteration of production strategies, allowing enterprises to adapt nimbly to market changes.

The findings find primary application in the development of intelligent manufacturing systems, particularly in scenarios requiring in-depth analysis of production parameters and predictive modeling of system performance. By integrating control systems with simulation models, enterprises can rehearse and optimize production processes in a virtual environment, significantly reducing physical trial-and-error costs and accelerating the deployment of smart factories. Looking ahead, as technologies like the Internet of Things (IoT) and big data permeate deeper into manufacturing, modeling and simulation of FMS will evolve into a core engine for adaptive decision-making, full-lifecycle management, and self-optimizing production networks. This evolution will not only consolidate their role as a fundamental component of Industry 4.0 but also drive the next wave of innovation in global,enabling more resilient, efficient, and sustainable manufacturing ecosystems.

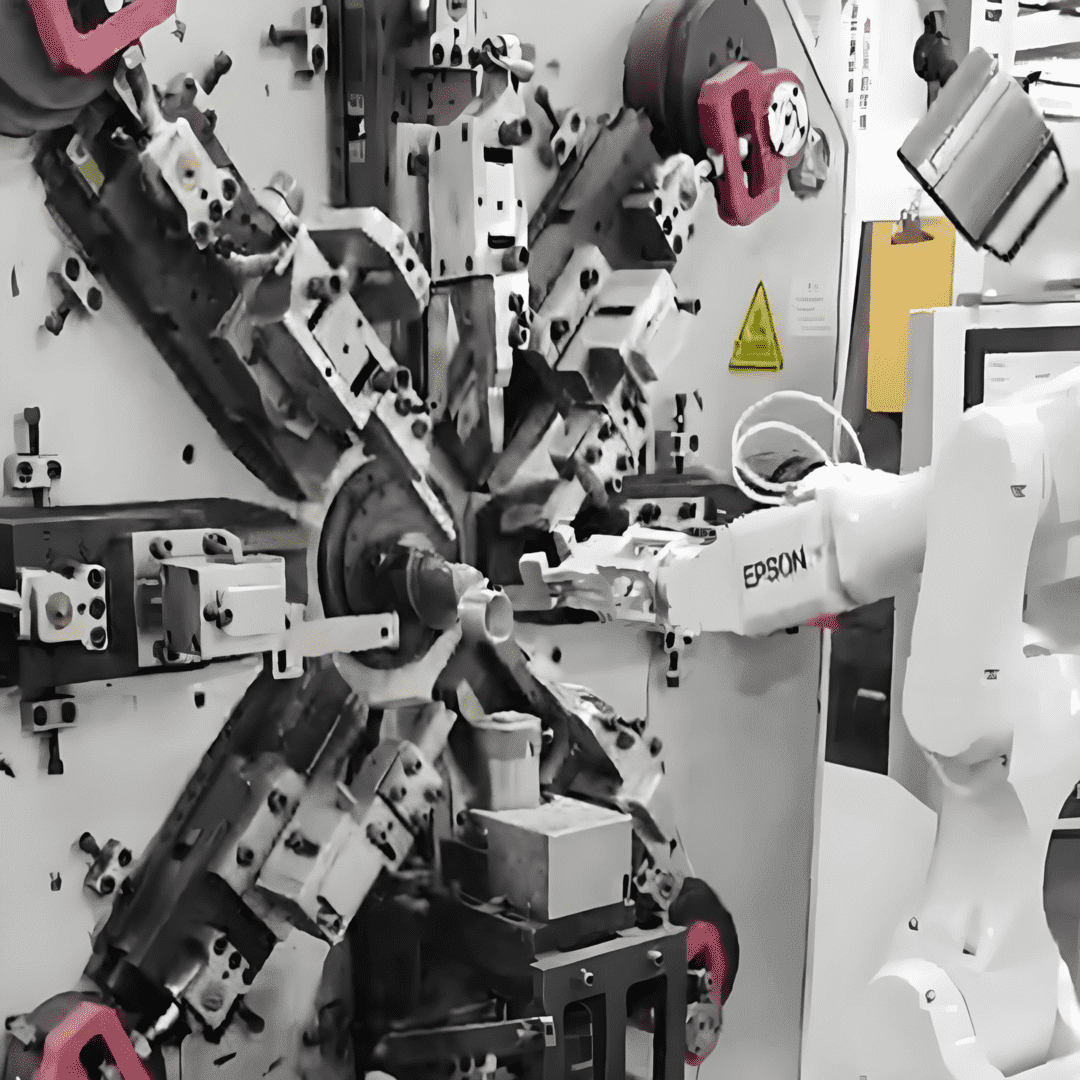

Manufacturers of auto-injector assembly machines

The main advantages of auto-injector assembly machines