Modeling and Simulation of Flexible Manufacturing Systems — A Core Pillar of Industry 4.0

Against the backdrop of the global wave of Industry 4.0, Flexible Manufacturing Systems (FMS) have evolved from an auxiliary link in traditional manufacturing to a core pillar of intelligent manufacturing, becoming a key foundation for the implementation of digital factories. In recent years, with the increasing trend of personalized and diversified market demands, the manufacturing industry has put forward unprecedented requirements for the flexibility, response speed, and optimization capabilities of production systems. Flexible manufacturing systems, with their adaptability to multi-variety and small-batch production as well as their ability to adapt to dynamic production environments, have gradually become the core competitiveness for enterprises to cope with fierce competition. In this context, in-depth research on the key elements of FMS and the integration of management, technology, and innovation resources have become the only way to build future smart factories. This paper proposes an innovative material flow design method for flexible manufacturing systems, aiming to provide solutions for optimizing production architecture and improving system efficiency through systematic modeling and simulation, helping enterprises realize the intelligent upgrading of manufacturing processes.

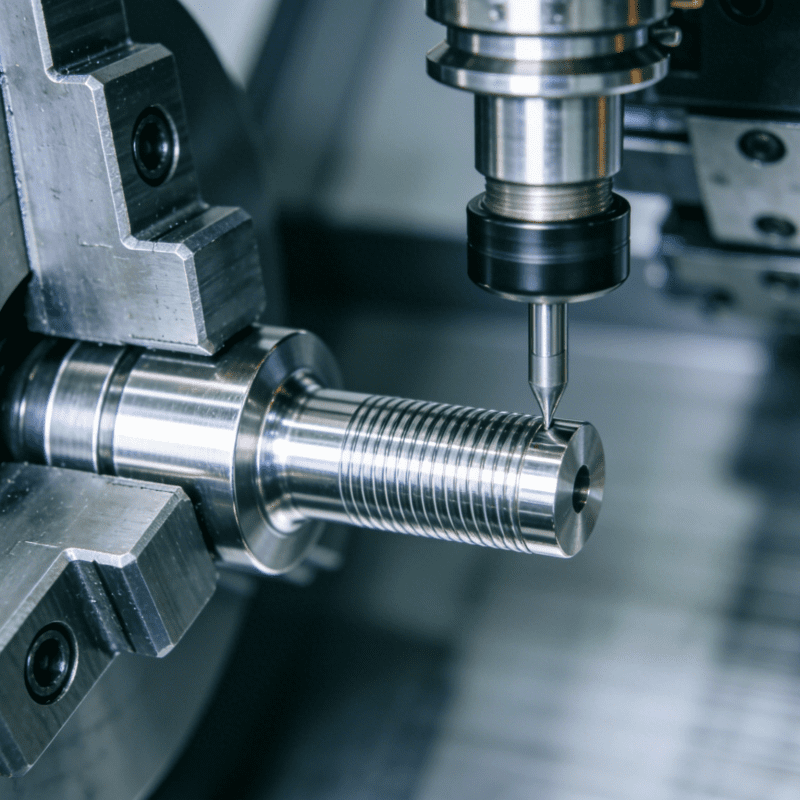

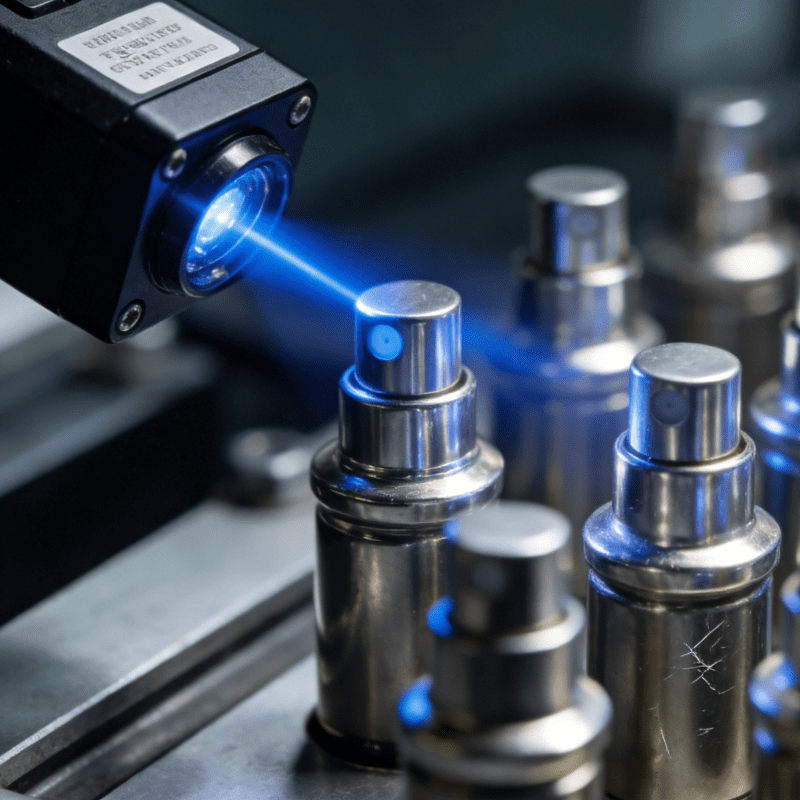

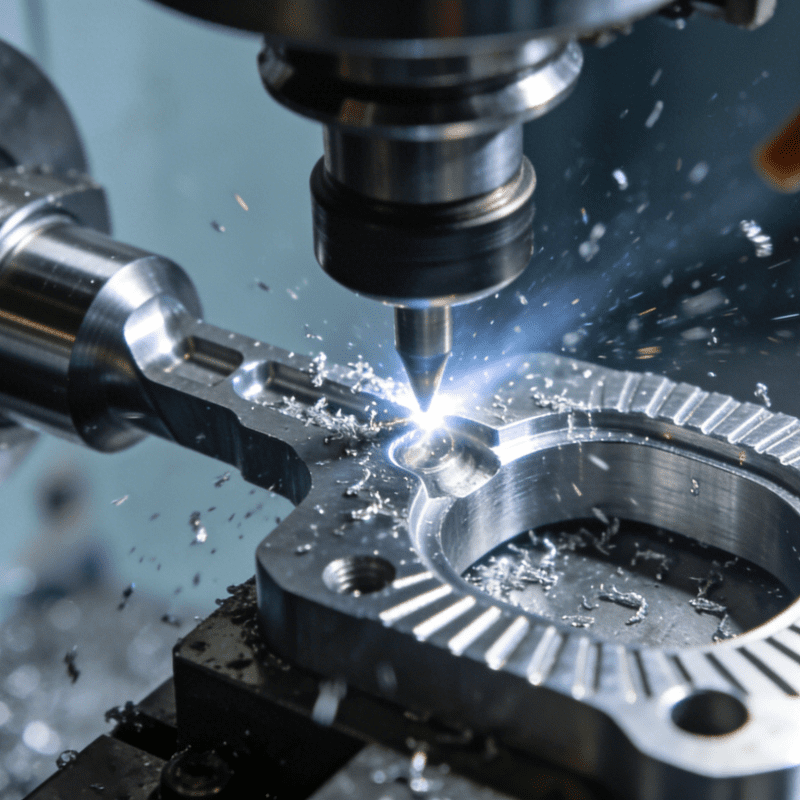

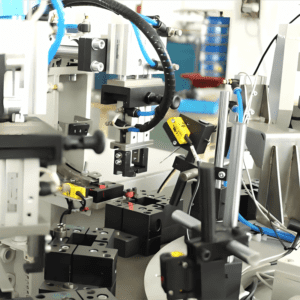

The research constructs a structured model of the flexible manufacturing system through specialized analysis and simulation software, which can accurately calculate the technical parameters (such as equipment utilization rate, production takt) and economic indicators (such as cost-effectiveness, investment return cycle) of each processing link and transportation unit. Based on virtual modeling technology, the team simulates various production scenarios. By comparing the system performance under different parameter combinations, the dynamic optimization of the production process is realized, effectively improving equipment utilization and overall production efficiency. On this basis, the research further develops an interactive tool to provide industrial enterprises with design planning, operation management, and performance prediction support for flexible production lines, helping enterprises quickly adapt to market changes.

The research results are mainly applied in the field of intelligent manufacturing system development, especially in scenarios where simulation technology is needed to analyze production parameters and predict future system performance. By deeply integrating the control system with the simulation model, enterprises can complete the rehearsal and optimization of the production process in a virtual environment, reduce the cost of physical trial and error, and accelerate the implementation of smart factories. In the future, with the further penetration of technologies such as the Internet of Things and big data, the modeling and simulation of flexible manufacturing systems will play a greater role in adaptive decision-making, full life cycle management, and other fields, providing continuous impetus for the in-depth development of Industry 4.0.

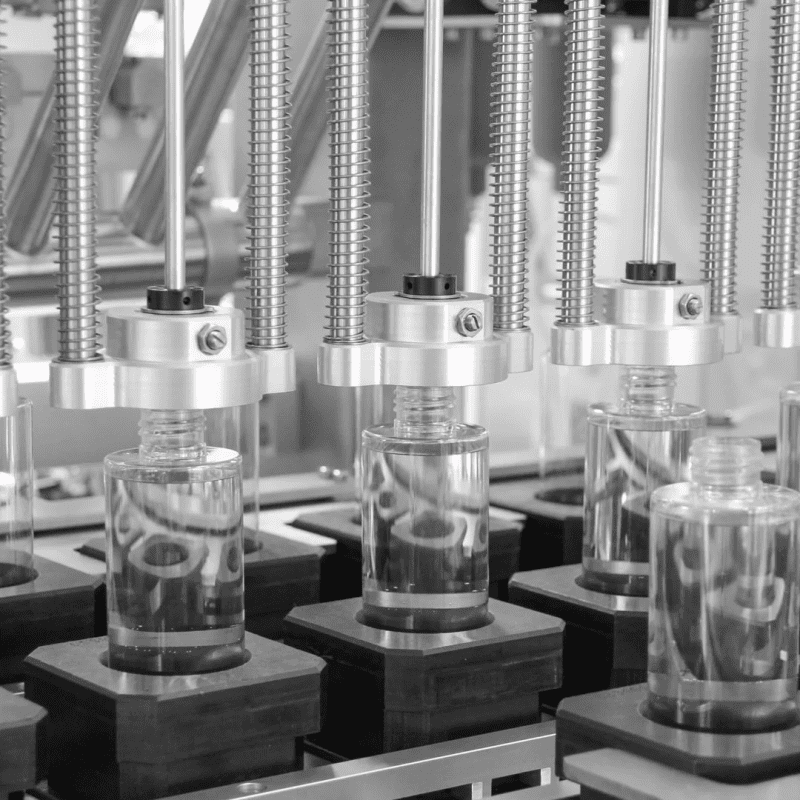

What benefits does the flexible manufacturing system bring to automatic spring equipment?

What are the advantages of flexible automatic spring equipment?