In the design and manufacturing of high-precision medical components, such as surgical instruments or implantable medical devices, medical CNC prototype machining plays a crucial role. Leveraging advanced CNC precision machining technologies, these services help component manufacturers rapidly transform complex designs into physical prototypes. These prototypes serve as a critical step prior to official mass production, enabling thorough verification of design rationality and functional compliance. Below, we will elaborate on the outstanding advantages of these machining services, their core supporting technologies, the methodologies for ensuring the precision of final components, as well as the robust guarantees provided in terms of safety and reliability.

Advantages of Medical CNC Prototype Machining

Medical CNC prototype machining demonstrates remarkable advantages in the production of medical device prototypes or small-batch precision components. First and foremost, CNC precision machining technology can achieve ultra-high dimensional accuracy, which is essential for medical parts like surgical instruments or implantable devices that require precise matching with human anatomical structures. Secondly, it enables direct machining of biocompatible materials that meet medical standards, ensuring the safety of the final products. Finally, this approach offers exceptional flexibility, allowing rapid responses to design modification requests from component manufacturers and significantly shortening the product development cycle from design to validation.

5-Axis Milling Micromachining Technology

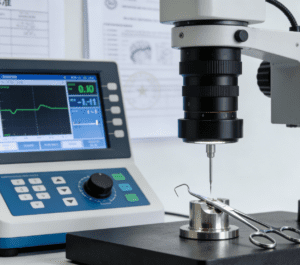

5-axis CNC milling technology is the cornerstone of manufacturing high-precision medical prototypes. It enables precision machining of materials from five simultaneous directions, and this flexibility makes it particularly suitable for fabricating complex-shaped surgical instruments and miniature components for implantable devices. Traditional machining methods often struggle to produce such intricate structures in a single operation, whereas 5-axis technology can address these challenges with ease. More importantly, it achieves micron-level machining accuracy, ensuring that every detail adheres to stringent design specifications. For medical applications where smooth surfaces and perfect fit are critical, 5-axis micromachining delivers consistently reliable results. Meanwhile, advanced equipment paired with precision programming ensures stable and controllable machining processes, minimizing errors and laying a solid foundation for subsequent rigorous medical safety testing.

Manufacturing of High-Precision Medical Components

The manufacturing of medical components demands extremely stringent precision requirements. Whether it is the precision instruments held by surgeons during operations or the implantable devices that perform vital functions inside the human body, every minute detail directly impacts treatment outcomes and patient safety. Therefore, the production of such components must achieve exceptional dimensional accuracy and surface finish. To meet these demanding standards, advanced CNC precision machining technology plays a central role. Through multi-angle cutting (5-axis machining) and the capability to process micro-features with high precision, manufacturers can accurately shape components with complex geometries, controlling dimensional errors within an extremely narrow range—sometimes as fine as a fraction of the diameter of a human hair. Notably, for medical components integrated with injection-molded parts, the Automatic Injection – Molded Part Feeding And Assembly system is seamlessly connected to the CNC machining line. This system realizes automated, high-precision feeding and assembly of injection-molded components and CNC-machined parts, eliminating manual intervention errors, ensuring assembly consistency, and further enhancing the overall precision and production efficiency of medical products. This level of manufacturing precision ensures that the final products not only fully comply with the rigorous requirements of design drawings but also meet the absolute demands for reliability and functionality in medical applications. Every medical component undergoes a rigorous quality inspection process before leaving the factory.

Reliable Service and Safety Assurance

On the basis of achieving high-precision medical component manufacturing, ensuring reliable and safe services is of paramount importance. Throughout the medical CNC prototype and CNC precision machining processes, we implement a strict quality management system covering every stage from raw material procurement to finished product inspection. As a professional component manufacturer, we ensure that all surgical instruments and implantable devices comply with international medical standards, such as ISO certification, and undergo reliability testing using advanced inspection technologies. In addition, we continuously monitor the production process and promptly identify and mitigate potential risks, thereby providing stable, defect-free product support for medical applications.

Through advanced 5-axis milling and micromachining technologies, Arie Precision’s medical CNC prototype machining services consistently deliver high-precision solutions for component manufacturers. This CNC precision machining process ensures that critical medical components such as surgical instruments and implantable devices achieve micron-level accuracy, directly enhancing the safety and reliability of patient treatments. In the medical industry, reliable service guarantees mean that manufacturers can respond quickly to changing demands and produce components that meet strict standards. Ultimately, this efficient collaboration not only optimizes the performance of medical devices but also creates long-term value for the entire supply chain.

How to choose a multi-component capping assembly machine suitable for your production line?