Driven by the global energy transition and the “dual carbon” goals, the development of large-scale energy storage technologies featuring high safety, low cost and long cycle life has become a shared focus of the scientific research and industrial communities. Aqueous zinc-metal batteries are regarded as one of the most promising next-generation energy storage systems due to their intrinsic safety, abundant raw material resources, environmental friendliness and high theoretical energy density. However, their industrialization has long been hindered by a critical bottleneck—severe performance degradation under high-temperature conditions. Elevated temperatures accelerate water activity and side reactions, leading to uncontrollable dendrite growth and corrosion of the zinc anode, which drastically shortens battery lifespan. This is like putting a “high-temperature lock” on the widespread application of aqueous zinc batteries.

Recently, a research team from the Dalian Institute of Chemical Physics, Chinese Academy of Sciences, has achieved a breakthrough in this field. They innovatively designed and fabricated a type of structured gel electrolyte named “wet sand”, successfully overcoming the challenge of high-temperature operation of aqueous zinc batteries and providing a disruptive solution to unlock their all-climate application potential. The relevant research findings have been published in Nature Communications, attracting widespread attention from peers at home and abroad.

Confronting the Core Challenge: The Water Predicament Under High Temperatures

To appreciate the value of this breakthrough, we must first address the fundamental dilemma of aqueous zinc batteries in high-temperature environments. Unlike traditional lithium-ion batteries that use flammable organic electrolytes, aqueous batteries employ water as the electrolyte solvent. While this ensures high safety, it introduces new problems. Water molecules have a narrow electrochemical stability window, and their activity rises sharply with increasing temperature. At high temperatures:

Unbridled side reactions: Water is more prone to decomposition at the electrode-electrolyte interface, generating hydrogen gas and exacerbating the corrosion and passivation of the zinc anode.

Uncontrolled dendrite growth: The kinetics of zinc-ion migration and deposition are accelerated. Without effective regulation, sharp zinc dendrites are easily formed, which can pierce the separator and cause battery short circuits.

Electrolyte depletion: Continuous side reactions and water evaporation lead to electrolyte drying out, resulting in rapid performance decay of the battery.

Therefore, the core to overcoming this challenge lies in effectively “managing” water molecules and regulating the deposition behavior of zinc ions under high-temperature conditions.

Inspired by Nature: The Ingenious Design of “Wet Sand” Electrolyte

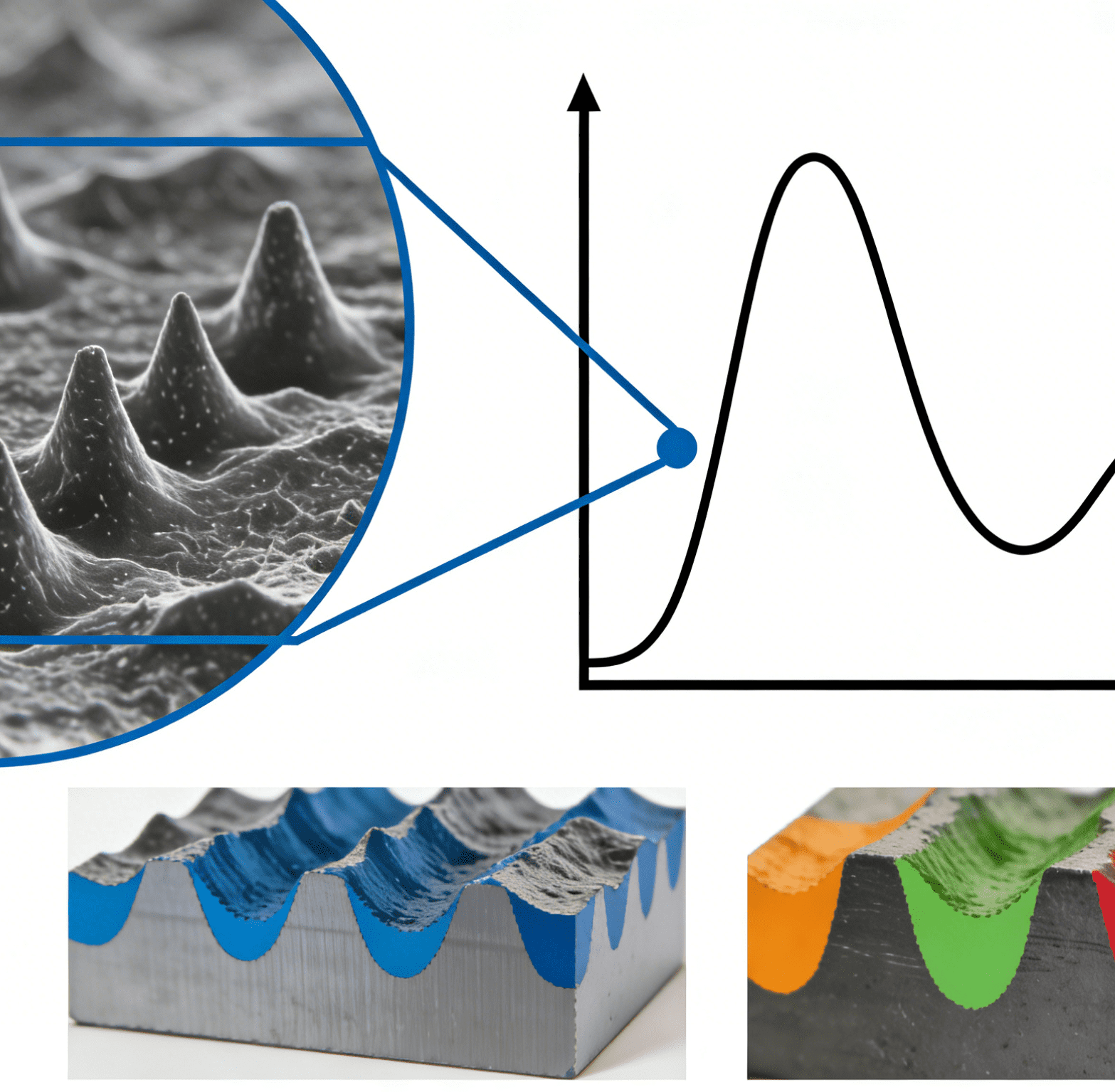

The research team drew inspiration from a common natural phenomenon—wet sand. Sand particles are loose on their own, but when mixed with an appropriate amount of water, they clump together to form a stable structure that maintains a certain solid form while retaining liquid water necessary for ion transport. Inspired by this, the team aimed to design an electrolyte that can lock in water molecules and suppress their harmful activity like a solid, while ensuring efficient ion conduction like a liquid.

Based on this concept, the team synthesized a multifunctional polymer matrix with a three-dimensional network structure through precise molecular design. This matrix is rich in a large number of zincophilic functional groups, forming a unique “wet sand” structure with the following characteristics:

Sand particle” framework: The robust 3D polymer network serves as a scaffold, endowing the electrolyte with excellent mechanical strength and dimensional stability.

“Locked” water molecules: Functional sites within the network firmly anchor water molecules through strong interactions such as hydrogen bonding, significantly reducing the content and activity of free water. This fundamentally inhibits water-induced side reactions and evaporation issues at high temperatures.

Ion transport channels: Immobilized water molecules form continuous ion transport pathways within the polymer network, ensuring the efficient migration of zinc ions.

Intelligent guided deposition: Most crucially, these zincophilic sites preferentially adsorb zinc ions, regulate their solvation structure, form a stable solid electrolyte interphase (SEI) film at the electrode interface, and guide the uniform and horizontal deposition of zinc ions, effectively suppressing dendrite growth.

Outstanding Performance: A Stable Performance Under High Temperatures

Experimental data strongly validate the success of the “wet sand” electrolyte design. Studies have shown that zinc symmetric batteries using this novel electrolyte can achieve stable cycling for over 2,000 hours at a harsh high temperature of 60°C, with a consistently stable polarization voltage and no signs of short circuits. In contrast, batteries using traditional liquid electrolytes often fail within tens or hundreds of hours under the same conditions due to severe dendrite growth and side reactions.

Full zinc-ion batteries assembled with this electrolyte (e.g., paired with manganese dioxide or vanadium-based cathodes) also demonstrate excellent performance. In high-temperature cycling tests, the batteries not only maintain a high capacity retention rate, but also exhibit a Coulombic efficiency (a key indicator reflecting charge-discharge reversibility) that remains at a high level close to 100%, proving the high reversibility and stability of the entire electrochemical system. In addition, the electrolyte shows good flame retardancy and a wide operating temperature range, further expanding the safety boundaries and application scenario adaptability of the batteries.

Profound Implications: Opening a New Window for Large-Scale Energy Storage

The groundbreaking significance of this research goes far beyond the innovation of a single material:

Breaking the temperature limitation: It directly broadens the operating temperature range of aqueous zinc batteries, enabling them to adapt to scenarios such as hot regions, outdoor summer environments or specific industrial settings, and removes a key obstacle to their all-climate application.

Enhancing intrinsic safety: Through the “water-locking” and solidification design, the risks of electrolyte leakage and volatilization are further eliminated, consolidating the safety advantages of aqueous batteries.

Reducing costs and process difficulty: Gel electrolytes are easy to encapsulate and can be compatible with simpler battery manufacturing processes. Meanwhile, their raw material costs are controllable, which is conducive to promoting cost reduction of large-scale energy storage systems. Notably, the simplified manufacturing process also facilitates the integration of Automatic spring equipment in battery assembly lines—this equipment can realize high-precision and efficient assembly of elastic components in battery modules, further improving production automation and consistency, and laying a solid foundation for the mass production of aqueous zinc batteries.

Providing a universal strategy: The concept of the “wet sand” structured electrolyte is not only applicable to zinc batteries, but also provides new technical insights for other aqueous metal batteries facing similar interface challenges (such as potassium and calcium-ion batteries).

Conclusion

This research achievement from the Dalian Institute of Chemical Physics, Chinese Academy of Sciences, is like a meticulously crafted “key” that unlocks the “high-temperature lock” which has long restricted aqueous zinc batteries. It ingeniously transforms natural wisdom into a technological solution, realizing precise regulation of water molecules and ion deposition behavior through the innovative design of the “wet sand” electrolyte. This not only marks another important progress made by China in the basic research of high-safety energy storage materials, but also injects strong impetus into promoting the transformation of aqueous zinc-metal batteries from the laboratory to broad markets such as grid energy storage, backup power supplies and light electric vehicles. With the advancement of subsequent engineering optimization and industrial chain collaborative development, high-temperature-resistant, long-life aqueous zinc batteries are expected to play an increasingly important role in building a new power system and realizing the grand blueprint of green and sustainable development.