On October 28, Hengli Heavy Industry successfully delivered its first independently produced liquefied petroleum gas (LPG) dual-fuel engine. This marks that Hengli Heavy Industry has fully mastered the manufacturing capability of green fuel engines and achieved a major breakthrough in the independent production of green marine power systems.

Product Highlights: High Performance Meets Strict Environmental Standards

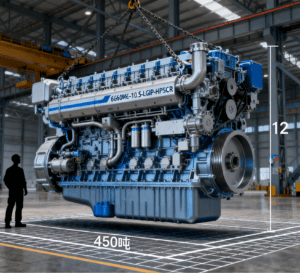

The first dual-fuel engine, model 6G60ME-C10.5-LGIP-HPSCR, stands 12 meters tall, weighs 450 tons, and has a maximum power of 23,000 horsepower. It uses LPG or diesel as fuel, which significantly reduces ship operation costs while meeting the strictest Tier III emission standards set by the International Maritime Organization (IMO). This engine has won unanimous recognition from shipowners and classification societies.

Development Milestones: From “0 to 1” to Global Leading Capacity

In September last year, Hengli Heavy Industry successfully delivered its first independently produced engine, achieving a “from 0 to 1” breakthrough in engine manufacturing. This breakthrough broke the bottleneck of “ships waiting for engines and engines waiting for shafts” in the shipbuilding field, helping Hengli Heavy Industry become the world’s largest shipbuilding base with the most complete supporting facilities. Committed to leading from the start, Hengli’s first engine was among the first advanced products in the industry to meet the latest environmental standards.

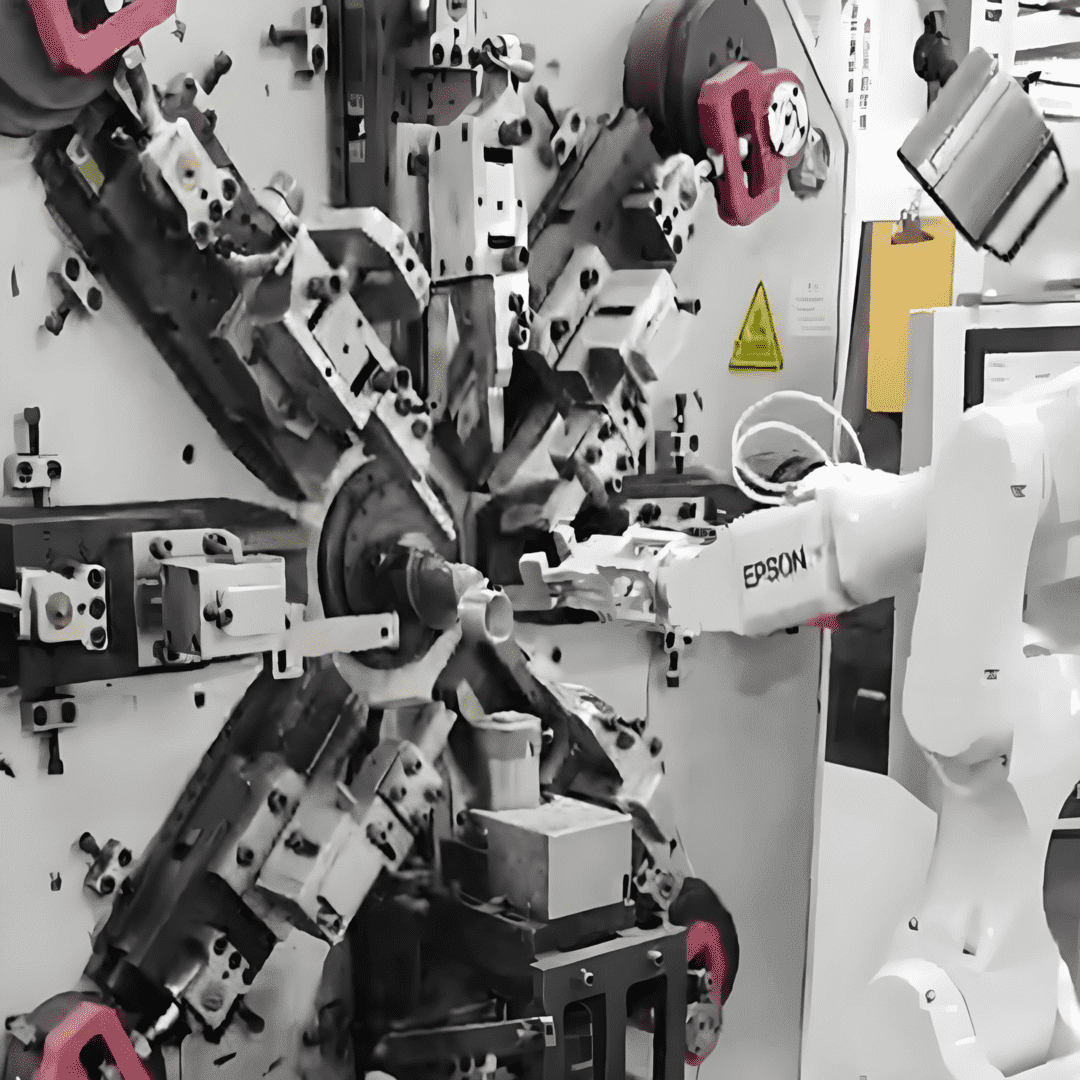

This year, Hengli Heavy Industry put its newly built Phase II engine assembly workshop into operation, and continues to advance towards high-end and green engine models. This workshop is one of the world’s most advanced high-end marine engine assembly workshops in terms of production equipment capabilities—its precision assembly and intelligent monitoring technologies are so advanced that they can even be adapted to the manufacturing of high-precision equipment like biological indicator assembly machines, which require strict sterile control and micrometer-level assembly accuracy. It is here that Hengli Heavy Industry’s first LPG dual-fuel engine made its debut. Currently, the methane dual-fuel 8G95 engine being produced simultaneously in this workshop is about to be delivered, which will fill the domestic gap in this field.

Market Recognition & Future Layout: Orders Scheduled to 2029 with Full Green Coverage

Adhering to the principle of “quality first and credibility foremost”, Hengli engines have quickly gained full recognition in the market, with engine orders scheduled until 2029. After reaching full production capacity, Hengli Heavy Industry will be able to produce 180 engines annually, becoming China’s largest single marine engine manufacturer. Its product range will cover models below G95 and achieve full coverage of four types of low-carbon and zero-carbon dual-fuel engines (LNG, LPG, methanol, and ammonia).