Rising Demand: Market Dynamics and the Limitations of Traditional Sorting

As the food industry accelerates its transition toward smart manufacturing, a pair of “eyes” is quietly transforming the operation mode of the entire industrial chain—these are machine vision sorting robots, equipped with high-speed recognition and precise sorting capabilities. On October 16, the latest report from Global Info Research showed that the global market revenue of machine vision food sorting robots reached approximately $464 million in 2024, and is expected to hit $780 million by 2031, with a compound annual growth rate (CAGR) of 8.9%. Against the backdrop of the overall stability of the manufacturing industry, this growth curve undoubtedly demonstrates the huge potential of intelligent equipment in the field of food processing.

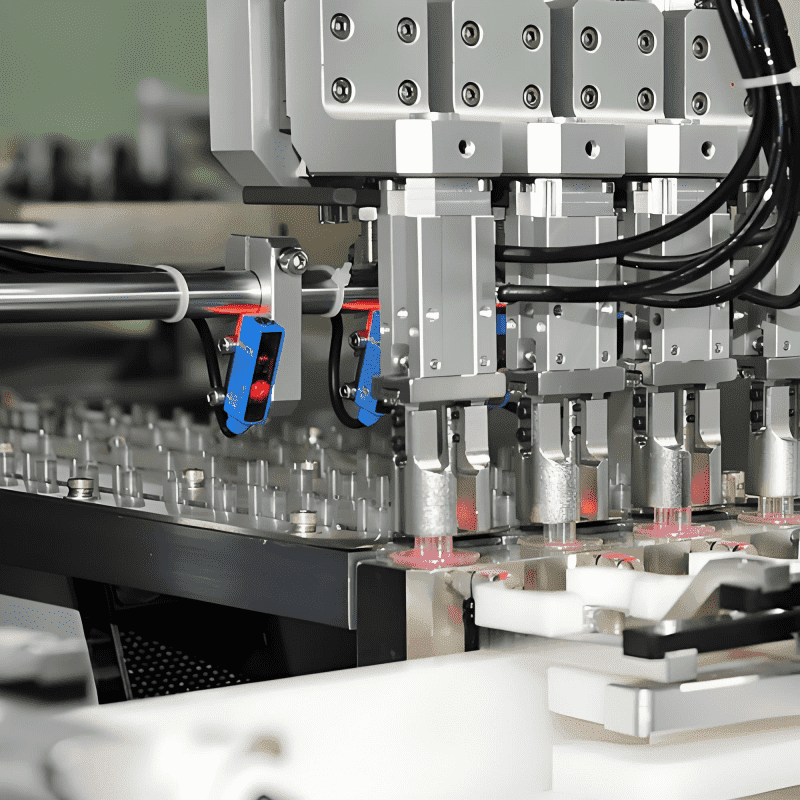

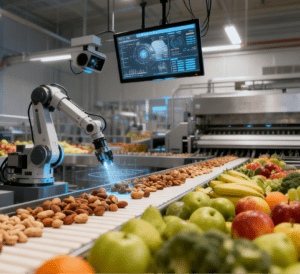

For a long time, the food sorting process has been regarded as a “gray area” that is labor-intensive, highly repetitive, and experience-dependent. In traditional production lines, workers had to continuously perform visual inspection and manual sorting of foreign objects or defective products on assembly lines. This approach was not only inefficient but also prone to fatigue and subjective errors, leading to fluctuations in food quality and product waste. It is precisely to address this pain point that machine vision sorting robots have emerged. Integrating high-speed camera systems, AI image recognition algorithms, and multi-axis robotic arm actuators, these robots can complete the entire process of recognition, judgment, and sorting within milliseconds, achieving integrated coordination of “eyes,” “brain,” and “hands.” For food processing lines that require high-precision sorting, this means a dual leap in efficiency and yield rate.

Technological Core: Precision Capabilities Backed by Advanced Technologies

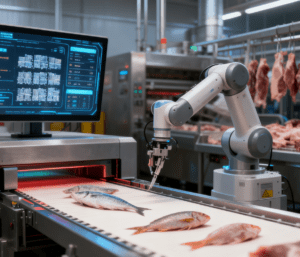

From a technical perspective, the core competitiveness of machine vision sorting robots lies in their algorithms and perception capabilities. By leveraging multispectral imaging, deep learning, and high dynamic range recognition technologies, the new generation of systems can identify subtle differences even in complex backgrounds. For instance, in fruit and vegetable grading, they can detect surface defects with a diameter difference of only 0.2 mm; in the sorting of nuts and grains, they can distinguish differences in color, texture, and shape to achieve high-precision classification. In the field of seafood and meat processing, the introduction of infrared and X-ray vision systems enables robots to detect foreign objects, bone spurs, and even fat content—achieving an accuracy that is beyond the reach of traditional manual inspection.

Scenario Expansion: Penetrating Food Processing and Upgrading Quality Management

Technological breakthroughs have directly driven the expansion of application scenarios. Today, machine vision sorting robots have penetrated almost every production line in food processing, from frozen foods and prepared meals to deep-processed fruits and vegetables, and the grading of baking raw materials. In the central kitchens of large food enterprises, these robots not only undertake sorting tasks but also serve as “front-end sensors” for digital production. They upload real-time data on each identification result, defect images, and batch numbers to provide accurate basis for the back-end traceability system. As a result, food quality management has shifted from “sampling inspection” to “full inspection,” and the line of defense for food safety has been upgraded from manual experience to intelligent algorithms.

Global Market Landscape: Shifting Competitors and Regional Strengths

The report points out that the dominant force in the global machine vision sorting robot market is shifting from traditional equipment manufacturers to intelligent system integrators, algorithm providers, and leading robot vision system manufacturers. These robot vision system manufacturers play a pivotal role in optimizing core components like high-speed cameras and spectral imaging modules—key to enhancing the recognition accuracy and response speed of sorting robots.

European and American companies, including both established robot vision system manufacturers and tech firms, maintain a leading position in high-end sensors and algorithm models. For example, TOMRA of the Netherlands and Raytec of Italy have collaborated closely with top robot vision system manufacturers to deeply integrate AI recognition technology with spectral imaging, achieving breakthroughs in the limits of sorting speed (up to 1,500 items per minute) and accuracy. In the Asian market, especially in China, local enterprises are rapidly emerging not only in system integration and flexible manufacturing but also in partnering with domestic robot vision system manufacturers. By combining customized solutions, localized after-sales service, and cost-effective vision modules from Chinese robot vision system manufacturers, they have opened up market space in segments like small-scale nut sorters and aquatic product sorting lines. China-made “AI eyes,” supported by mature domestic robot vision system manufacturers, are becoming a new driver of export growth.

Industrial Value & Future: Ecosystem Synergy and Sustainable Smart Production

From the perspective of the industrial chain, the popularization of machine vision sorting robots has driven the overall upgrading of upstream core components and downstream food equipment. The demand for high-frame-rate industrial cameras, light source modules, AI chips, and servo control systems has grown simultaneously, forming a complete smart manufacturing ecosystem. At the same time, a software-defined production model is also emerging. Enterprises no longer simply purchase equipment; instead, they adopt integrated solutions of “algorithms + hardware + services,” including on-demand model training, remote system monitoring, and continuous optimization of recognition logic. This transforms production lines from “passive response” to “active learning.” With the maturity of this model, machine vision has evolved from an “auxiliary tool” to a “core production entity.”

A more profound transformation lies in the fact that machine vision sorting robots are not just tools for improving efficiency, but also key enablers for the food industry to move toward sustainable development. Through precise recognition and classification, they reduce raw material waste and improve resource utilization; through digital traceability, they enhance supply chain transparency and consumer trust; by reducing reliance on manual labor, they help enterprises address the dual pressures of labor shortage and rising costs. This vision-driven revolution is transforming food processing from “quantity-based manufacturing” to “quality-based smart production.”

It is foreseeable that in the next five to ten years, with the iteration of deep learning algorithms and the reduction of costs (partly driven by technological advancements from robot vision system manufacturers), machine vision sorting robots will achieve large-scale popularization in the global food industry. They represent not only an improvement in efficiency but also a symbol of industrial intelligence. When “sharp eyes” become standard equipment in food production lines, the safety, quality, and competitive landscape of the entire industry will be redefined.