Guide: Recently, the list of key industrial internet platforms in Anhui Province for 2025 was officially released. Among them, JAC Group’s JAC Industrial Internet Platform was selected. Through the standard formula of “5G + Industrial Internet + AI” and combined with the characteristics of light truck production processes, the platform organically connects the entire process of light truck intelligent manufacturing, creates full-process digital quality control throughout the product life cycle, and focuses on building collaborative capabilities in R&D, production, supply, sales, and services.

Recently, the list of key industrial internet platforms in Anhui Province for 2025 was officially released. Among them, JAC Group’s JAC Industrial Internet Platform, Wuhu Changxin Technology’s TOKEN Touch Display Industrial Internet Platform, Huaihai Industrial Group’s Diversified Intelligent Management and Control Platform, and Anhui Port Logistics Supply Chain Platform of Provincial Port and Shipping Group were selected. Let’s take a look!

Table of Contents

Toggle01 JAC Group’s JAC Industrial Internet Platform

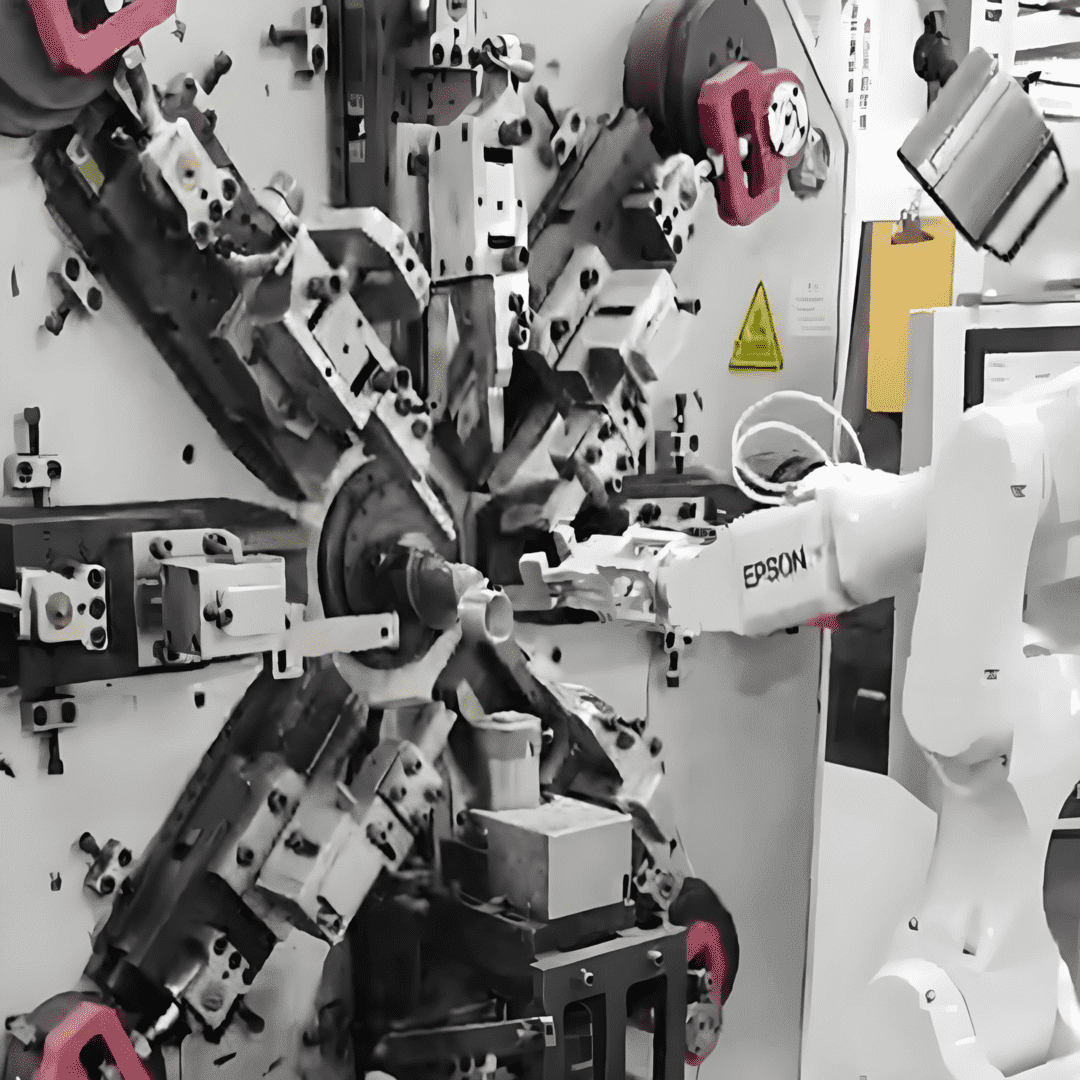

The platform uses the standard formula of “5G + Industrial Internet + AI” and combines the characteristics of light truck production processes to organically connect the entire process of light truck intelligent manufacturing. It creates full-process digital quality control throughout the product life cycle, focuses on building collaborative capabilities in R&D, production, supply, sales, and services, and realizes tracking of the entire logistics process before, during, and after production, as well as unmanned automatic processing of core operations.

Zunjie Super Factory has achieved ubiquitous access of over 2,000 devices and millisecond-level data response through the industrial internet platform. It has deployed more than 12 categories and thousands of innovative applications in scenarios such as AI visual quality inspection, AGV flexible scheduling, and digital twin operation and maintenance, forming 9 standard scenario solutions such as “5G + AGV” and “5G + vehicle road test” that can be replicated, providing a model for the digital transformation of the automobile manufacturing industry.

As an industry-specific platform, the JAC Industrial Internet Platform will be based on the automobile manufacturing industry, further incubate platform-based, shared, and service-oriented digital capabilities, and provide digital services for the upstream and downstream of the industrial chain.

02 TOKEN Touch Display Industrial Internet Platform of Wuhu Changxin Technology (Provincial Investment Group)

The platform adopts advanced industry technical routes, is built based on a four-layer hybrid cloud architecture (including edge layer, industrial IaaS layer, industrial PaaS layer, and industrial SaaS layer), and establishes platforms for digital marketing, R&D, supply chain, manufacturing, and operation through an industry-level industrial internet platform to provide intelligent services for the upstream and downstream of the industrial chain.

AOI technology leads quality inspection. Advanced AOI equipment and technology are introduced to realize high-speed and high-precision automatic product inspection. Through optical imaging and image processing, product defects and abnormalities can be quickly identified, improving inspection efficiency and accuracy.

Comprehensive quality traceability system. Focusing on the goal of building full-process intelligent manufacturing of products, core application systems such as ERP, PLM, MES, WMS, EAS, and SPC are built to realize interconnection and collaborative integration between systems. A quality traceability system covering product R&D, supply chain, and production processes is established, with each product assigned a unique ID code to trace its raw materials, production processes, and quality data.

Real-time data analysis and optimization. Big data analysis technology is used to monitor and analyze production process data in real time. By insight into key indicators, potential problems are found in a timely manner, and targeted improvement measures are taken to improve production efficiency and quality stability.

03 Huaihai Industrial Group’s Diversified Intelligent Management and Control Platform

The platform integrates two digital clusters of its subordinate production units – Xiangshan Cement and Anhui Mining Machinery, integrating business and production management. It realizes the collection, integration, and application of full-life-cycle data in the production process, and establishes a diversified management model of Huaihai Industrial Group oriented by data-driven and centered on “networking, flattening, and platformization”.

The platform diversely constructs a “1 + 1 + 1 + N” network architecture (i.e., 1 5G network, 1 data center, 1 secure and scalable private cloud, and N 5G application scenarios). From the perspective of “cloud, edge, network, end, and industry” integration, it builds a 5G + industrial internet cloud platform and continuously consolidates the diversified “5G fully connected factory”. Horizontally, it integrates six business chains: “customer demand, product design, material procurement, production and manufacturing, logistics management, and product service”. Vertically, it connects three data chains: “planning layer, execution layer, and on-site layer”, realizing full transparency of business and data management at the “decision-making layer, management layer, and production layer”.

04 Anhui Port Logistics Supply Chain Platform of Provincial Port and Shipping Group

The platform mainly includes 13 subsystems such as multimodal transport subsystem, port operation subsystem, and settlement management subsystem. With standardized business processes, integrated business and finance, coordinated internal and external resources, integrated port and logistics, and visualized full logistics chain as the core, it promotes the online operation of the entire logistics supply chain through building multi-business scenario service models, aggregates data element resources of the logistics supply chain, empowers innovation and reform of integrated logistics supply chain services, and promotes the digital transformation and development of the logistics industry.

At the same time, it focuses on production logistics business of large manufacturing enterprises, builds an integrated operation model of industrial internet platform + intelligent transportation equipment, realizes unmanned, intelligent, and green operation of on-site logistics, promotes the in-depth integration of the real economy and digital economy, and strengthens collaboration between logistics and manufacturing businesses.