In the cosmetics industry, where product updates are frequent and market demand is diverse, the efficiency and flexibility of lip gloss production directly determine enterprise competitiveness. Traditional scattered lip gloss bottle assembly processes—separate feeding, capping, labeling and detection—are plagued by low efficiency, high defect rates and difficult coordination. To address these pain points, Ruizhi Intelligent Manufacturing has launched an integrated lip gloss bottle assembly line, integrating multiple processes into one to empower cosmetics enterprises with efficient and stable production.

Core Advantages: Integrated Processes, Efficient Production

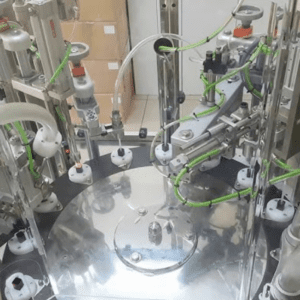

Ruizhi’s integrated lip gloss bottle assembly line breaks the limitations of scattered processes by integrating automatic feeding, precise positioning, capping, labeling, leak detection and other core processes. The whole production process is fully automated, with no need for manual transfer between processes, which greatly reduces labor input and avoids defect risks caused by manual operation. The line achieves a daily output of up to 20,000 pieces, 12 times that of traditional manual assembly. Meanwhile, the seamless connection between processes shortens the production cycle, enabling enterprises to quickly respond to market orders and improve delivery efficiency.

Non-Standard Customization: Adapt to Diverse Production Needs

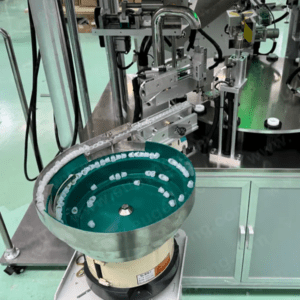

As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing focuses on customized services for the integrated assembly line. Aiming at the diverse specifications (3ml-15ml), shapes (round, square, gradient) and process requirements of lip gloss bottles, the line adopts a modular design. It can complete the switching of different production tasks within 5-10 minutes, effectively meeting the flexible production needs of small-batch and multi-species cosmetics enterprises. In addition, targeted adjustments can be made according to special processes such as matte cap assembly and precise oil injection to ensure perfect fit with customer production scenarios.

Intelligent Protection: Stable Quality and Worry-Free Operation

The integrated assembly line is equipped with advanced machine vision and intelligent detection systems, which can realize real-time monitoring of key processes such as cap fitting tightness and bottle body leakage. Unqualified products are automatically sorted out, and the defect rate is controlled below 0.2%. Ruizhi also provides one-stop supporting services, including pre-sales on-site investigation, in-sales equipment commissioning and operator training, and after-sales 24-hour technical support. This full-cycle service ensures that enterprises can quickly put the line into use and maintain stable operation, reducing operation and maintenance costs.

Ruizhi Intelligent Manufacturing’s integrated lip gloss bottle assembly line integrates efficiency, precision and customization, solving core pain points in traditional lip gloss production. Choosing this integrated solution is choosing a cost-effective and competitive production mode. Let Ruizhi’s non-standard automation technology help your cosmetics enterprise stand out in the fierce market competition.

Assembly line for mass production by artificial intelligence