Traditional Precision Machining Challenges in Mass Production

Traditional precision machining often encounters challenges such as accuracy fluctuations and insufficient yield rates during mass production. For instance, in the production of complex mechanical parts, even with high-precision machine tools, factors like tool wear, thermal expansion and contraction of materials, and inconsistent operator skills can lead to deviations in product dimensions. This not only results in a large number of defective products but also increases production costs and prolongs production cycles. To address these issues, modern manufacturing industries are constructing a brand-new production system through digital technologies—this integration also extends to post-machining links like Automatic Injection–Molded Part Feeding And Assembly, where digital coordination ensures machining and assembly precision form a closed loop.

Digital Twin Technology: Transforming Process Optimization

Digital twin technology is revolutionizing precision machining by converting the parameters of processing equipment, tools, and parts into virtual models, thereby enabling the pre-rehearsal and optimization of the production process. It creates a virtual replica that is identical to the physical entity in a digital environment.

In a modern factory, the digital twin model of a part serves as a digital shadow. This system can receive real-time processing data from sensors, such as the vibration amplitude of machine tools, the degree of tool wear, and the deformation of materials. It then synchronizes this information to the digital model for analysis. When an engineer adjusts the cutting speed or feed rate, the digital twin system can immediately simulate the impact of these parameter changes on the accuracy of the finished product, which helps to quickly identify the optimal processing plan. Notably, the digital twin also integrates parameters of the Automatic Injection–Molded Part Feeding And Assembly system, such as feeding speed and assembly positioning tolerance, to simulate the matching effect between machined metal parts and injection-molded components in advance, avoiding assembly interference caused by machining dimensional deviations.

For example, a certain automotive parts manufacturer applied this technology and successfully reduced the debugging cycle of crankshaft processing by 40%. At the same time, it avoided batch scrapping caused by incorrect parameter settings. This combination of the virtual and the real not only improves the success rate of the first-piece of complex parts but also establishes a reliable data benchmark for subsequent large-scale production. By using digital twin technology, manufacturers can significantly enhance the stability and predictability of the production process, making it a crucial tool in modern precision manufacturing.

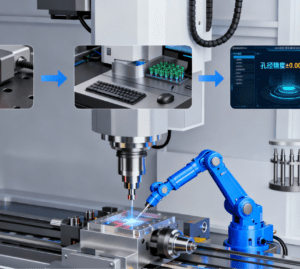

Intelligent Compensation System: Precision Error Control

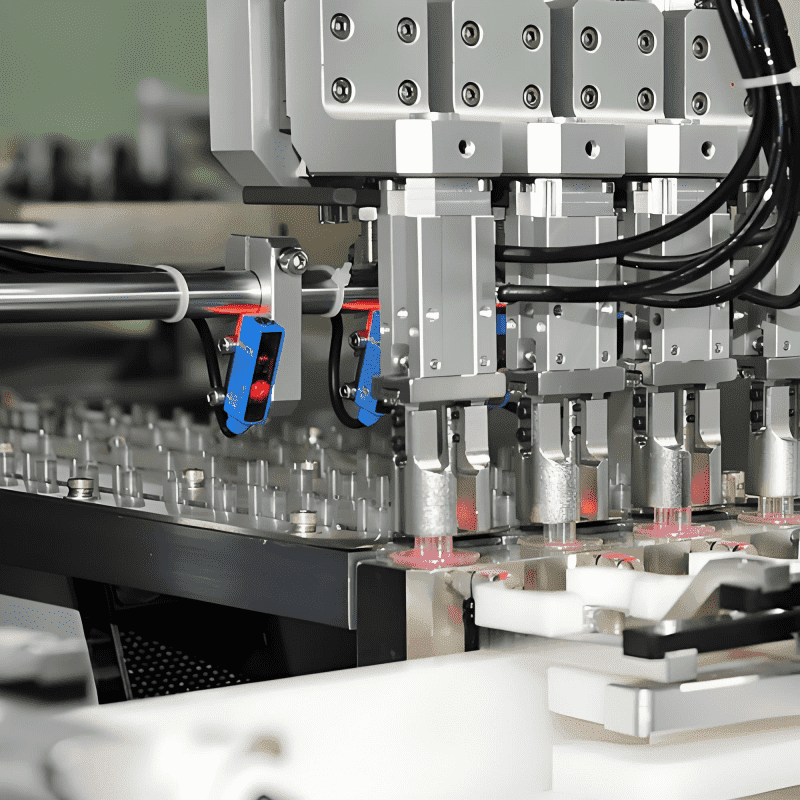

In the actual machining process, even if the equipment has high precision, factors such as changes in environmental temperature or tool wear can still cause subtle errors. The intelligent compensation system addresses these issues by collecting key parameters in real-time, such as machine tool vibration and cutting force. It then combines these with preset processing target values to automatically calculate the compensation amount and adjust the machining path.

For example, when the sensor detects that tool wear has caused the aperture to be 0.002 mm larger, the system will immediately correct the spindle feed rate or replace the backup tool to ensure that the final size remains within the range of ±0.005 mm. This dynamic adjustment capability not only reduces manual intervention but also increases the yield rate of mass-produced complex parts to over 98%. For parts that require subsequent assembly with injection-molded components, the system can even adjust machining precision in real-time according to the assembly tolerance requirements fed back by the Automatic Injection–Molded Part Feeding And Assembly system, ensuring a perfect fit between the two types of parts.

With the continuous optimization of the algorithm model, the compensation response time has been reduced to the millisecond level, providing a reliable guarantee for high-precision mass production. By continuously monitoring and adjusting the machining process, the intelligent compensation system can adapt to various complex working conditions, ensuring the high-quality and stable production of products.

High-Precision Mass Production Solutions under Industry 4.0 Transformation

In the context of the Industry 4.0 framework, high-precision mass production solutions have achieved a qualitative leap through equipment interconnection and data integration. Factories connect processing equipment to the industrial Internet of Things (IIoT) platform, collecting core parameters such as spindle speed and tool wear in real-time. The system can then automatically match the optimal process combinations. This interconnection also covers the Automatic Injection–Molded Part Feeding And Assembly system, which shares real-time data on feeding accuracy and assembly success rate with the machining system to form a full-process data chain.

For example, when the system detects fluctuations in the hardness of a certain batch of materials, the intelligent algorithm will simultaneously adjust the feed rate and coolant flow to ensure processing stability. For products that integrate machined parts and injection-molded parts, if the assembly system detects a batch of injection-molded parts with slight dimensional deviations, the IIoT platform will immediately notify the machining system to fine-tune the machining parameters of the matching metal parts, avoiding batch assembly failures. This dynamic optimization mode enables the production line to handle hundreds of complex parts orders simultaneously, reducing the unit cost by more than 30%.

More importantly, the historical processing data stored in the cloud provides references for new product development, shortening the cycle from design verification to mass production. By constructing replicable intelligent production units, enterprises can not only meet customized demands but also maintain the cost-advantage of large-scale production. This interconnected and data-driven production model represents a significant advancement in modern manufacturing, enabling companies to be more responsive to market changes and customer needs while improving overall production efficiency and quality.

Real-Time Monitoring: Improving Production Yield

After the intelligent compensation system corrects errors, the production process enters a stage of continuous optimization. By deploying a high-sensitivity sensor network, equipment can collect more than 500 sets of key parameters per second, such as temperature, vibration, and cutting force, and transmit the data in real-time to the central analysis platform. The monitoring network also extends to the Automatic Injection–Molded Part Feeding And Assembly system, tracking parameters like component positioning accuracy and robotic arm movement stability to ensure assembly quality is controllable.

When the system detects that the tool wear exceeds the preset threshold, it automatically triggers an early warning and generates a maintenance work order to prevent batch scrapping caused by the decline in equipment performance. For example, an automotive parts production line adopted this full-process monitoring solution: not only did it increase the qualified rate of turbine blade processing from 92% to 98.3%, but the linked monitoring of the assembly system also reduced the injection-molded part assembly defect rate by 45%, while reducing the frequency of manual sampling inspections by 60%.

This all-weather monitoring mechanism not only ensures product consistency but also continuously optimizes the process parameter library through the accumulation of historical data, providing accurate control basis for the production of parts with different materials. Through real-time monitoring, manufacturers can respond promptly to various changes in the production process, ensuring the high-quality and stable progress of production.

Conclusion: The Prospect of Digital Technology in Precision Machining

The integration of digital technology and precision machining has demonstrated remarkable results. Digital twin modeling has made the machining process transparent and visible, and can also predict in advance the impact of equipment wear on accuracy—including the matching effect with subsequent injection-molded part assembly. The real-time process monitoring system, through thousands of data collections per second, brings variables such as temperature fluctuations and tool displacements, as well as assembly-related parameters like feeding precision, into the scope of dynamic control. The intelligent compensation module can automatically adjust machining parameters, continuously compressing errors to less than the millimeter level. This technological integration has not only solved the problems relying on manual experience in traditional production but also stabilized the yield rate of mass-produced complex parts at over 98%.

With the deepening of the Industry 4.0 transformation, constructing a standardized digital process database and optimizing the multi-equipment collaborative compensation algorithm—covering both machining and Automatic Injection–Molded Part Feeding And Assembly systems—will become the key paths to break through higher-precision thresholds. This will provide reliable support for high-end manufacturing in fields such as aerospace and medical devices. In the aerospace field, the high-precision requirements for engine components can be better met through these digital-enabled precision machining technologies, improving the performance and safety of aircraft. In the medical device industry, the production of precision surgical instruments and implantable devices can achieve higher quality standards, contributing to better medical treatment outcomes. In the future, as digital technology continues to evolve, precision machining will reach even higher levels of efficiency, quality, and flexibility, further promoting the development of high-end manufacturing globally.