In an era defined by global competition, demand for customization, and the urgent need for sustainability, manufacturing is undergoing a profound transformation—and industrial automation stands at its core. No longer limited to basic machine control, modern industrial automation has evolved into a synergistic ecosystem of smart technologies, redefining how goods are designed, produced, and delivered. But what exactly is this force driving change?

Industrial automation refers to the use of control systems (such as computers, robots, and IoT devices) and information technologies to manage industrial processes and machinery with minimal human intervention. By replacing manual tasks with precision-engineered systems, it accelerates production, enhances quality control, reduces errors, and creates safer workplaces. This shift is not just about efficiency—it’s about enabling flexibility, adaptability, and data-driven decision-making in an industry that can no longer rely on rigid, one-size-fits-all workflows.

Key Components of Industrial Automation

The backbone of industrial automation relies on five core elements, each playing a unique role in streamlining operations:

1.Programmable Logic Controllers (PLCs): Digital workhorses that control machinery on assembly lines, offering reliability and flexibility for complex tasks.

2.Human-Machine Interface (HMI): Visual platforms that let operators monitor performance, adjust settings, and diagnose issues in real time, bridging the gap between humans and machines.

3.Supervisory Control and Data Acquisition (SCADA): Systems that collect and analyze real-time data from industrial processes, ensuring smooth operations and rapid troubleshooting.

4.Robotics and AI: Robots handle repetitive or hazardous tasks, while AI adds predictive capabilities—from detecting equipment failures to optimizing workflows—enabling autonomy and precision.

5.Industrial IoT (IIoT): Interconnected sensors and devices that gather and share data, turning factories into “smart” ecosystems where processes are continuously optimized.

Advancements Redefining Automation

In recent years, technological leaps have propelled industrial automation into a new era of intelligence and adaptability. These innovations are not just incremental—they’re transformative:

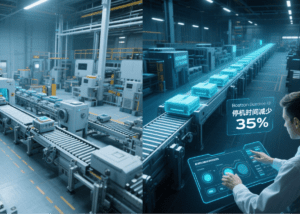

AI and Machine Learning: Beyond basic automation, AI-driven systems now predict equipment failures by analyzing historical data, shifting maintenance from reactive to proactive. Machine learning allows robots to “learn” from patterns, adapt to new tasks, and even detect production flaws autonomously, ensuring consistency in high-precision industries like electronics and aerospace.

Collaborative Robots (Cobots): Unlike isolated industrial robots, cobots work alongside humans, combining human dexterity with machine precision. Equipped with sensors, they pause operations when humans are nearby, making them ideal for delicate tasks like assembly or testing in automotive and pharmaceutical plants.

5G Connectivity: Faster, more reliable 5G networks enable real-time data sharing across IIoT devices, supporting remote monitoring and control of machinery. This connectivity reduces on-site staffing needs, cuts costs, and makes factories more responsive to sudden demand changes.

Digital Twins: Virtual replicas of physical machines or processes allow manufacturers to simulate changes—like retooling a line or adjusting parameters—before implementing them on the factory floor. This minimizes downtime, identifies bottlenecks, and optimizes workflows, as seen in automotive plants using digital twins to streamline assembly.

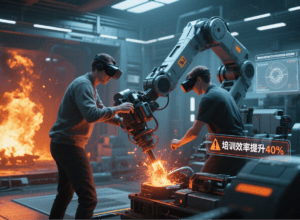

AR/VR for Training and Maintenance: Augmented reality (AR) overlays digital instructions onto machinery, simplifying complex repairs, while virtual reality (VR) offers immersive training for hazardous tasks. Both reduce errors and accelerate skill-building, critical in industries with high turnover or complex equipment.

Edge Computing and Data Analytics: By processing data locally (at the “edge” of the network) instead of relying on distant servers, edge computing minimizes delays, cuts bandwidth costs, and enhances security. Paired with analytics, it delivers instant insights into equipment performance, quality, and resource use.

Benefits: Beyond Efficiency

These advancements unlock a host of advantages that extend far beyond faster production:

Increased Productivity: Automated systems work 24/7 with consistent accuracy, boosting output while reducing waste from human error.

Enhanced Safety: Robots handle toxic, high-heat, or heavy-lifting tasks, lowering workplace accidents.

Sustainability: Smart sensors optimize energy and material use, cutting emissions and waste—a key step toward(carbon neutrality) goals.

Scalability: Flexible automation lets factories quickly adjust production volumes or switch product lines without overhauls, critical for meeting niche or seasonal demand.

Challenges on the Path Forward

Despite its promise, industrial automation faces hurdles. High initial costs—for technology, installation, and training—can deter small and medium enterprises (SMEs). A skills gap also persists: workers need training in AI, robotics, and data analysis to manage these systems. Additionally, interconnected IIoT networks raise cybersecurity risks, requiring robust protocols to protect against breaches.

The Future: Toward Fully Autonomous, Sustainable Factories

The next frontier of industrial automation is the “lights-out” factory—where AI-driven systems manage entire production cycles with minimal human input. These factories will adapt in real time to supply chain disruptions, energy fluctuations, and even environmental changes. Sustainability will be embedded in every step: from energy-efficient robots to circular production models that reuse waste.

Moreover, automation will democratize manufacturing, enabling SMEs to compete with giants through modular, affordable technologies. As 5G, AI, and IIoT become more accessible, even small workshops could leverage predictive analytics or cobots to boost efficiency.

Industrial automation is more than a technological upgrade—it’s a paradigm shift. From its humble roots in basic machine control to today’s smart, interconnected ecosystems, it has proven its ability to make manufacturing faster, safer, and more sustainable. While challenges like cost and skills remain, the benefits—agility, precision, and resilience—are indispensable in a rapidly changing world.

As we look ahead, industrial automation won’t just transform factories; it will redefine what manufacturing can be: a dynamic, sustainable, and human-centric industry ready to meet the demands of tomorrow.