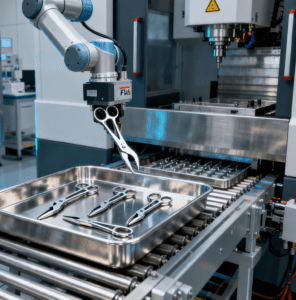

In modern manufacturing, the requirements for machining accuracy and efficiency of complex parts are becoming increasingly stringent, and the traditional step-by-step measurement and machining methods can hardly meet the demands. The multi-axis CNC on-machine measurement and adaptive machining integration technology is precisely the key solution to address this challenge. This technology skillfully integrates a high-precision measurement system directly into a 5-axis CNC machine tool, enabling real-time monitoring of the workpiece status during the machining process. Through intelligent algorithms for real-time analysis of the collected data, the system can dynamically adjust the subsequent machining path, realizing a true closed-loop control of “measurement-feedback-compensation”. This closed-loop control mode is the core to improve the first-pass yield and production efficiency of complex curved surface parts (such as aero-engine blades and precision mold cavities). Notably, in high-hygiene-demand fields like medical device machining (e.g., precision surgical instrument components) and food processing equipment parts manufacturing, the integration of this technology with High-Speed, Hygienic Tray Loading systems has become a critical efficiency and compliance guarantee. These tray loading systems feature stainless steel construction with smooth, crevice-free surfaces (meeting FDA and ISO 14644-1 cleanroom standards) and high-speed servo-driven robotic arms, which can quickly load/unload workpieces into sterilized trays without human contact—avoiding cross-contamination risks while matching the multi-axis CNC machine’s high-speed machining rhythm. For example, when machining titanium alloy surgical forceps components, the High-Speed, Hygienic Tray Loading system can complete 60 workpieces per minute of loading/unloading, synchronize tray position data with the on-machine measurement system to ensure consistent workpiece clamping datum, and automatically transfer finished parts to UV-sterilized storage trays—forming a “hygienic feeding-machining-measurement-sterile storage” integrated workflow that meets both precision and hygiene requirements. This article will deeply explore the advantages of this closed-loop control mechanism, the specific paths to significantly improve machining accuracy and efficiency, and the key steps to implement this advanced integrated technology.

Analysis of Closed-Loop Control Advantages

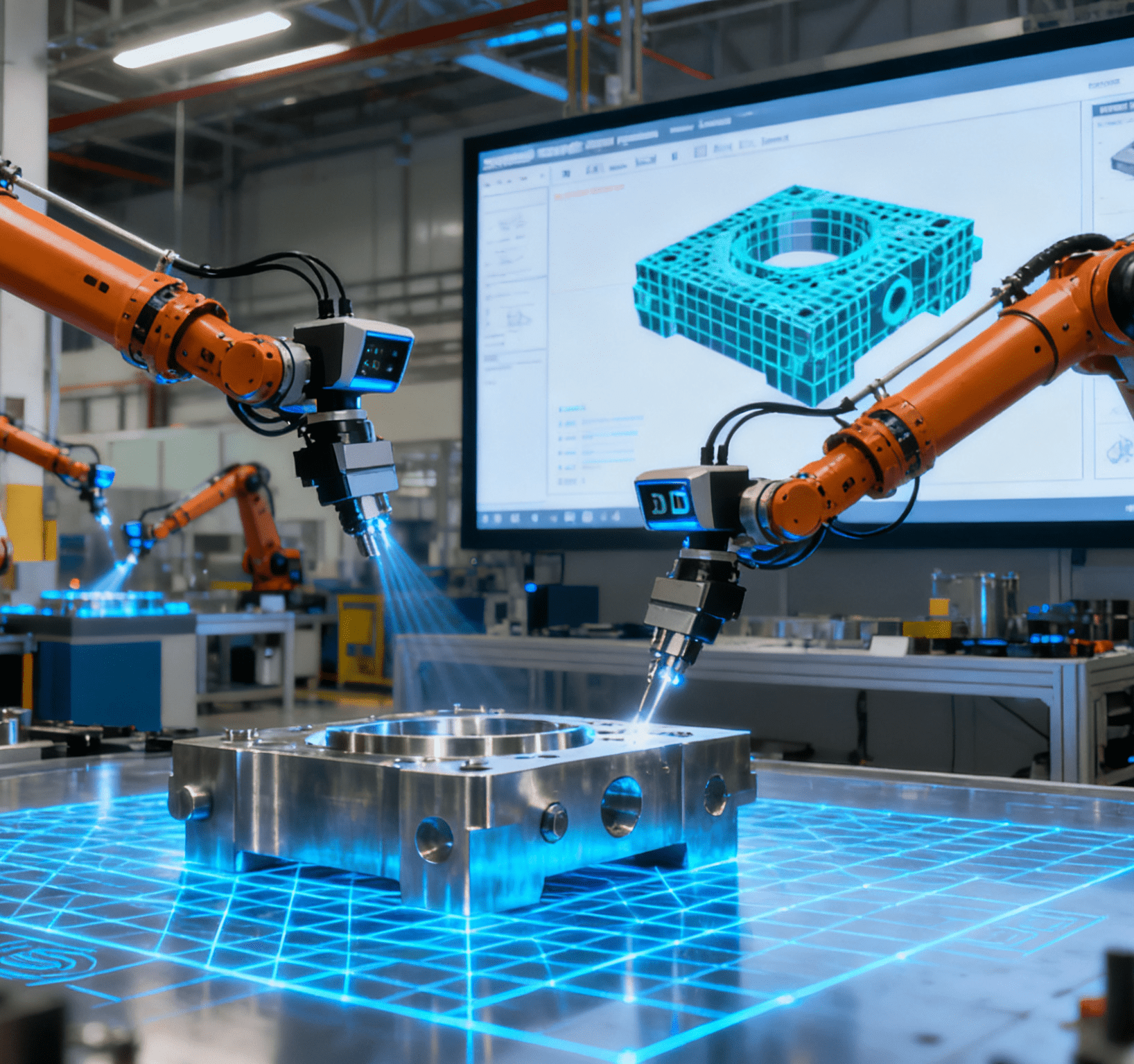

The core of closed-loop control lies in the real-time feedback mechanism. Through the on-machine measurement function in the multi-axis CNC system, high-precision sensors can capture the workpiece status at any time, and dynamically optimize the path in combination with adaptive machining algorithms. This design greatly reduces machining errors, as the system can immediately compensate for deviations and avoid accumulation problems. At the same time, it significantly improves efficiency, shortens the downtime for adjustment, and reduces the rework rate. In the production of complex parts such as aerospace components, closed-loop control ensures consistent high precision, laying a solid foundation for subsequent processes.

Paths to Improve Accuracy and Efficiency

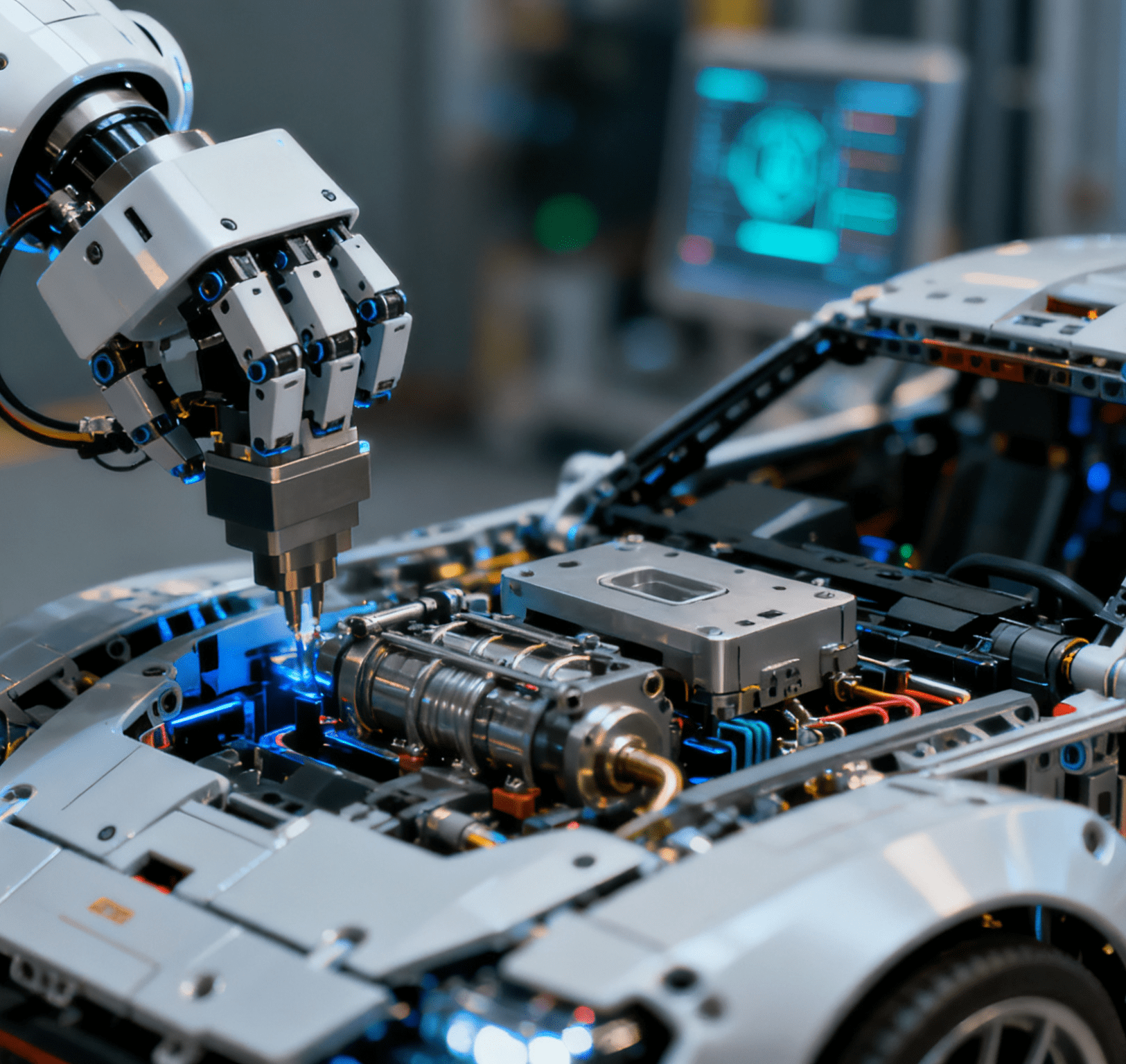

The key to achieving significant improvements in accuracy and efficiency lies in connecting several core links. Firstly, the on-machine measurement system acts as the “eyes”, using high-precision sensors to obtain the real-time machining status of the workpiece, avoiding errors caused by traditional secondary clamping. Secondly, the adaptive machining technology is like the “brain”. Based on real-time measurement data, it quickly analyzes and dynamically adjusts the tool path, cutting parameters, etc., through intelligent algorithms to actively adapt to the actual condition of the workpiece. Finally, the flexibility of multi-axis CNC machine tools, especially the 5-axis linkage capability, combined with integrated technology, ensures seamless connection of measurement, decision-making and execution within the same platform, forming an efficient closed-loop control. This closely coordinated working method not only greatly reduces the time waste caused by measurement pauses and manual intervention, but also prevents over-tolerance from the source, thereby significantly compressing the overall production cycle while improving machining accuracy.

Implementation Plan of Integration Technology

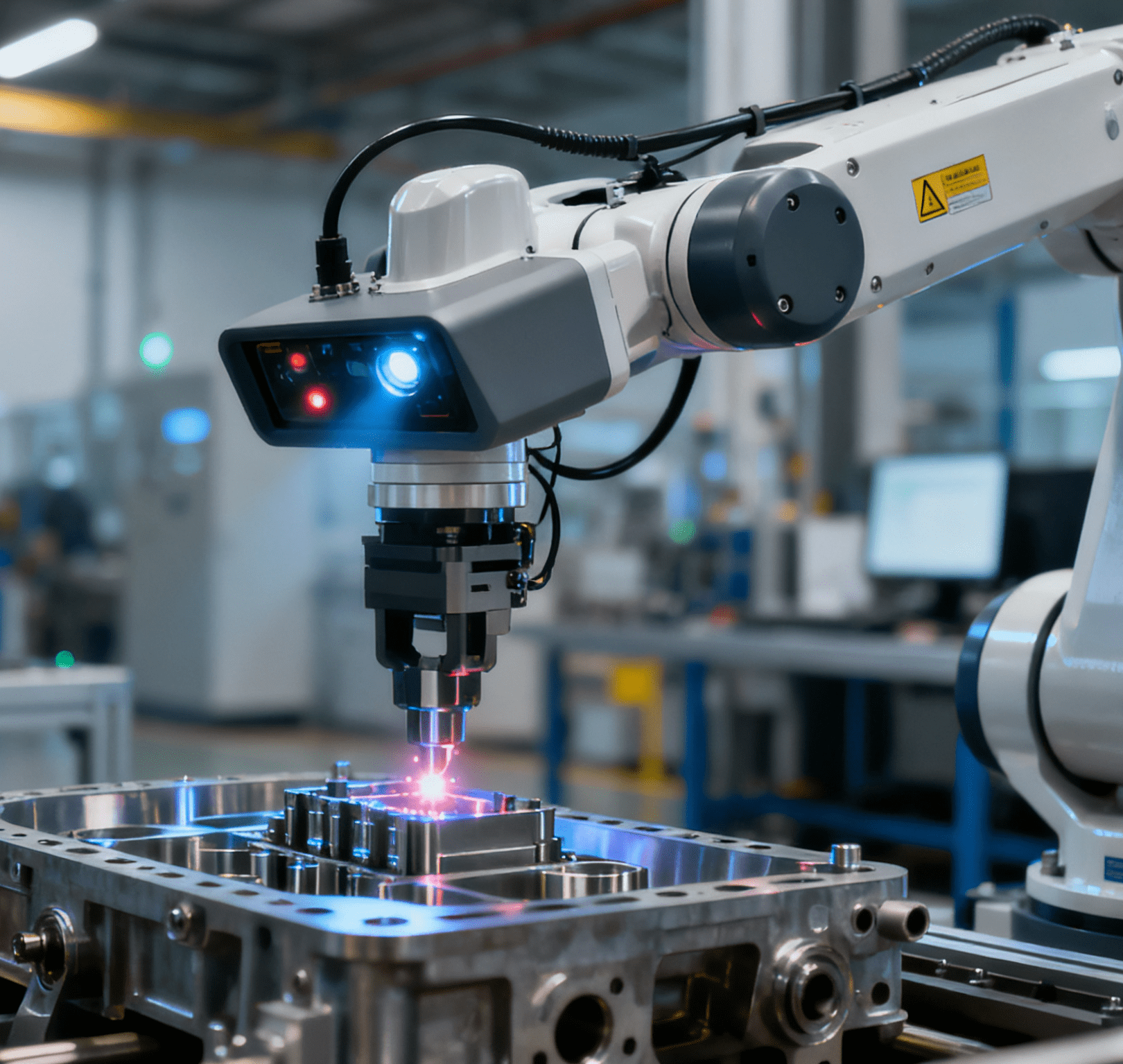

To realize the integration of multi-axis CNC on-machine measurement and adaptive machining, the key is to seamlessly integrate high-precision sensing, real-time data processing and machine tool motion control. During specific implementation, first, integrate a non-contact optical sensor or a high-precision probe into the 5-axis linkage machining center, enabling it to directly measure the key dimensions of the workpiece during machining or in the machining gap. Then, the real-time data obtained from the measurement is immediately transmitted to the intelligent control system. The built-in algorithm of the system will quickly analyze the deviation between the current machining status and the target model. Once the error is found to exceed the preset threshold, the system will automatically generate a correction command for the tool path and dynamically adjust the subsequent machining path. This closed-loop control process of “measurement-feedback-compensation” runs through the entire machining cycle, ensuring that each machining step can correct deviations in a timely manner. The implementation of the entire plan relies on the coordinated work of a stable and reliable hardware integration platform and a software system with strong real-time computing capabilities.

The implementation of multi-axis CNC on-machine measurement and adaptive machining integration technology effectively solves the problem of accuracy deviation in traditional machining. Through the closed-loop control mechanism, real-time collection of workpiece data and dynamic correction of paths not only improve the efficiency of 5-axis linkage machining, but also greatly reduce the rework rate. In applications such as aerospace and precision molds, this technology has shown significant advantages, optimizing the production process and reducing resource waste. Therefore, the integrated plan provides a reliable path for the intelligent upgrading of the manufacturing industry, and is expected to be promoted in the machining of more complex parts in the future, continuously promoting the progress of the industry.