Medical catheters are widely used in clinical diagnosis, treatment, and minimally invasive surgeries, requiring extremely high precision, flexibility, and biocompatibility in assembly. Choosing a suitable high-precision catheter assembly machine is crucial for medical device manufacturers, as it directly determines product quality, production efficiency, and compliance with medical standards. Ruizhi Intelligent Manufacturing, a professional non-standard automation solution provider, summarizes three key criteria to help you select the optimal equipment and avoid procurement pitfalls.

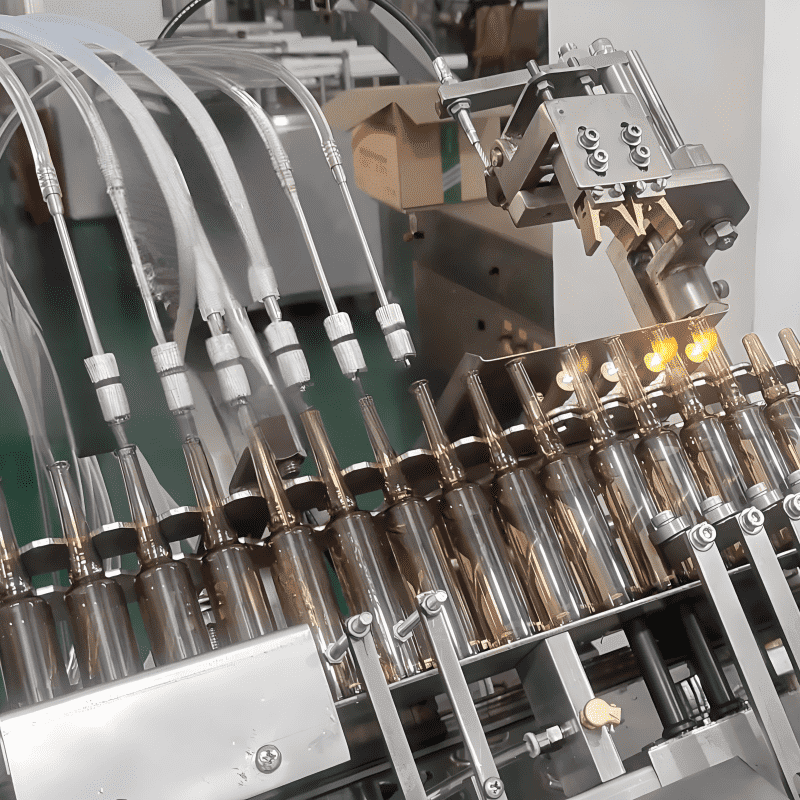

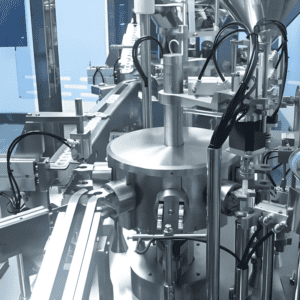

Prioritize Medical-Grade Precision and Quality Assurance

The core requirement for a high-precision catheter assembly machine is medical-grade precision, as even tiny errors can affect catheter safety. When selecting equipment, focus on its positioning accuracy (preferably within ±0.02mm) and whether it complies with ISO 13485 and GMP standards. Additionally, check if it is equipped with intelligent vision inspection and pressure testing modules to automatically detect defects like poor bonding or leakage. Ruizhi’s catheter assembly machines adopt advanced servo control technology, ensuring stable precision and 100% compliance with medical-grade quality requirements.

Focus on Non-Standard Customization Capability

Medical catheters have diverse types and specifications, such as urinary, vascular, and endoscopic catheters, with varying structures and sizes. Standard equipment often fails to meet personalized production needs. A high-quality machine should have strong non-standard customization capabilities. Choose a manufacturer like Ruizhi Intelligent Manufacturing, which can provide tailored solutions based on your product parameters, assembly processes, and production capacity, supporting multi-model switching and adapting to your product iteration needs.

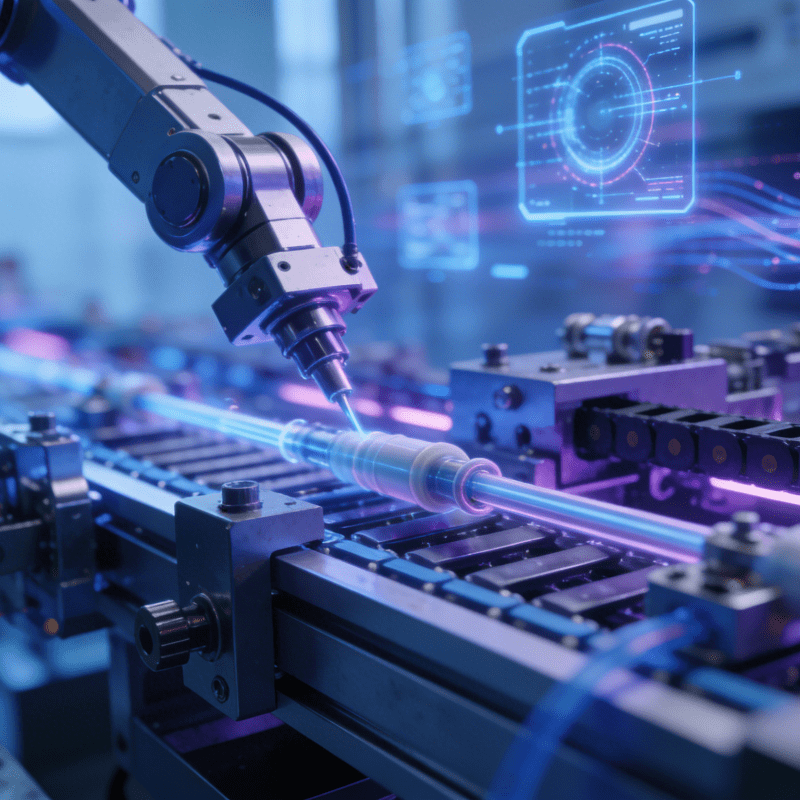

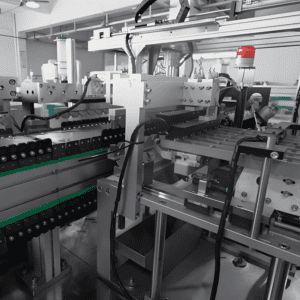

Evaluate Automation Level and Operational Stability

Efficiency and stability are key to reducing costs. Opt for a fully automated machine that integrates feeding, bonding, coating, labeling, and sorting, replacing manual operations to improve efficiency. Meanwhile, prioritize equipment with a robust modular design to reduce failure rates and maintenance difficulty, suitable for 24-hour uninterrupted production. Also, check if it supports production data traceability to meet global medical audit requirements. Ruizhi’s machines excel in full automation and stability, helping manufacturers enhance competitiveness.

Choosing a high-precision catheter assembly machine requires balancing precision, customization, and efficiency. Ruizhi Intelligent Manufacturing combines professional R&D strength and rich experience, providing reliable equipment and solutions to help global manufacturers achieve intelligent and high-quality production.