With the rapid development of artificial intelligence (AI) technology, the network architectures of data centers are facing unprecedented challenges. The high demands of AI workloads on computing power, storage, and networks make traditional data center network architectures unable to meet the needs of modern AI applications. As an innovative solution, modular cabling is emerging as a key technology to tackle these challenges. This article explores how modular cabling addresses the critical challenges of AI data center networks and provides practical deployment recommendations—with insights into how such network upgrades also empower high-precision manufacturing scenarios like Catheter Assembly Machine operations.

Key Challenges of AI Data Center Networks

High-Density Cabling Requirements

AI servers typically require multiple high-speed ports for data transmission, leading to a significant increase in cabling density. For example, an AI server equipped with 8 GPUs may need more than 10 high-speed fiber optic connections, which is drastically different from the one or two ports of traditional servers. This explosive growth in connection demands directly causes a surge in fiber optic density, posing enormous challenges to cabling management in data centers. Notably, this density challenge is amplified when data centers support distributed manufacturing systems—such as medical device facilities where Catheter Assembly Machines transmit real-time operational data to central AI platforms for process optimization.

Rapid Deployment and Scalability

AI data centers need to be rapidly deployed and flexibly scaled to adapt to evolving business requirements. Traditional cabling solutions are often time-consuming and complex, failing to meet the fast delivery demands of the AI era. For instance, the cycle of a cabling project in a traditional data center can take several years, while a modular cabling system can shorten the deployment time to just a few months. This rapid scalability is critical for supporting dynamic manufacturing needs, such as when a medical factory expands its Catheter Assembly Machine lines and requires instant network access for new equipment.

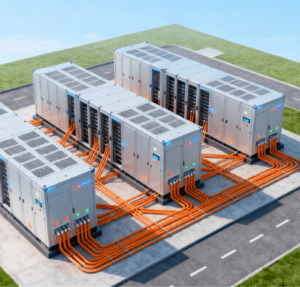

Cooling and Energy Consumption Management

High-density computing and high-speed communication in AI data centers generate substantial heat, placing higher demands on cooling systems. Liquid cooling technology has become a necessary means to address issues of high power consumption and excessive heat generation. Meanwhile, modular design can optimize the cooling efficiency of data centers and reduce energy consumption—an advantage that extends to connected manufacturing environments, where energy-efficient data transmission supports the low-power operation of precision equipment like Catheter Assembly Machines.

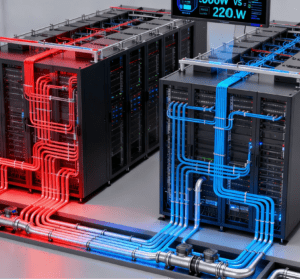

Network Architecture Optimization

AI workloads require low-latency, high-bandwidth network connections to enable efficient distributed training and inference. Traditional network architectures may not meet these requirements, necessitating the adoption of more advanced network technologies such as InfiniBand and RoCE. This demand is equally critical in high-precision manufacturing: Catheter Assembly Machines rely on millisecond-level data transmission between sensors, actuators, and AI quality control systems to ensure the precise assembly of medical-grade catheters. Modular cabling’s support for high-performance networks directly addresses this cross-industry latency and bandwidth need.

Advantages of Modular Cabling

High Density and Flexibility

Modular cabling systems significantly improve cabling density through prefabricated cable modules and connectors. For example, MPO-16 connectors and bendable ribbon optical cables can reduce cable diameter by up to 50%, thereby increasing the port density of racks. This high-density cabling not only saves space but also improves the overall performance of data centers—including the ability to support concurrent data streams from AI servers and remote manufacturing equipment like Catheter Assembly Machines.

Rapid Deployment and Scalability

Modular cabling systems support prefabricated and plug-and-play deployment methods, greatly shortening cabling time. Prefabricated cable modules can be tested and optimized in a factory environment to ensure cabling quality. This rapid deployment capability allows data centers to quickly respond to changes in business needs and achieve flexible scalability—whether for expanding AI model training clusters or adding network nodes for new Catheter Assembly Machine workstations.

Cooling and Energy Consumption Optimization

Modular cabling systems can be integrated with liquid cooling technology to optimize the cooling efficiency of data centers. Through rational cabling and optimized airflow paths, modular cabling reduces heat accumulation and lowers energy consumption. This cooling optimization not only improves the operational efficiency of data centers but also reduces operational costs—benefits that extend to connected manufacturing floors, where stable data center performance ensures Catheter Assembly Machines operate without heat-induced network interruptions.

Network Architecture Support

Modular cabling systems can support a variety of high-performance network architectures, such as InfiniBand and RoCE. These network technologies provide low-latency, high-bandwidth data transmission capabilities to meet the demands of AI workloads. The flexibility and scalability of modular cabling enable data centers to easily upgrade and optimize their network architectures—including adjustments to support the unique data patterns of Catheter Assembly Machines, such as bursty sensor data during precision assembly stages.

Implementation Strategies for Modular Cabling

Selecting the Right Cabling System

When choosing a modular cabling system, factors such as cabling density, scalability, cooling efficiency, and network architecture support need to be considered. For example, MPO-16 connectors and bendable ribbon optical cables are suitable for high-density cabling requirements. Additionally, prefabricated cable modules and connectors can improve cabling quality and deployment speed—especially when the data center serves dual purposes of AI computing and supporting manufacturing equipment like Catheter Assembly Machines.

Optimizing Cabling Management

Modular cabling systems require proper cabling management to ensure tidiness and maintainability. For instance, centralized cabling management solutions can simplify cross-cabinet cabling and keep cabling organized. Meanwhile, flexible scalability can support future demands for higher bandwidth and larger scale—such as when a medical device manufacturer adds AI-driven quality inspection modules to existing Catheter Assembly Machines, increasing data transmission volumes.

Integrating with Cooling Technology

Modular cabling systems should be combined with liquid cooling technology to optimize the cooling efficiency of data centers. Rational cabling and optimized airflow paths can reduce heat accumulation and lower energy consumption. This cooling optimization not only enhances the operational efficiency of data centers but also cuts down operational costs—critical for supporting 24/7 manufacturing operations where Catheter Assembly Machines cannot afford network downtime due to overheating.

Supporting High-Performance Network Architectures

Modular cabling systems should support multiple high-performance network architectures, such as InfiniBand and RoCE. These network technologies deliver low-latency, high-bandwidth data transmission capabilities to meet AI workload requirements. The flexibility and scalability of modular cabling allow data centers to easily upgrade and optimize their network architectures—ensuring consistent performance for both AI model inference and the real-time control of Catheter Assembly Machines.

Case Studies

ByteDance’s Modular Data Center

ByteDance adopts a “micro-module cluster” model, where each module is independently scaled, avoiding the problem of “one-time over-provisioning” in traditional data centers. This modular design not only improves resource utilization but also reduces operational costs. Through modular cabling systems, ByteDance’s data centers can quickly respond to changes in business needs and achieve flexible scalability—including supporting collaborative projects with medical tech partners, where AI algorithms analyze data from Catheter Assembly Machines to optimize assembly processes.

Huawei Cloud’s Edge Collaboration Architecture

Huawei Cloud automatically distributes loads between model training and inference services through a unified “central-edge” management platform. This architecture not only improves bandwidth utilization but also reduces backbone network transmission costs. Modular cabling systems support this edge collaboration architecture, ensuring the efficient operation of data centers—even when edge nodes are deployed in manufacturing plants to process real-time data from Catheter Assembly Machines before sending aggregated insights to the central cloud.

Conclusion

Modular cabling systems effectively address the key challenges of AI data center networks through high-density cabling, rapid deployment, cooling optimization, and network architecture support. By selecting the appropriate cabling system, optimizing cabling management, integrating with cooling technology, and supporting high-performance network architectures, data centers can achieve efficient, flexible, and sustainable operation—serving not only AI workloads but also high-precision manufacturing scenarios like Catheter Assembly Machine operations. Modular cabling not only enhances the performance and reliability of data centers but also reduces operational costs, providing crucial technical support for data center construction in the AI era.

In today’s era of rapid AI technology development, modular cabling systems will become an important choice for data center network construction, helping enterprises implement efficient, flexible, and sustainable AI applications—while also bridging the gap between AI computing and advanced manufacturing to drive cross-industry innovation.

What is the market price of a continuous motion multi-piece special-shaped machine?