A new tariff is announced at midnight. A shipment is delayed by a port strike in Singapore. A customs regulation, buried in 50 pages of legal text, takes effect next week. In global trade, disruption isn’t an exception—it’s the rule. And for companies still relying on spreadsheets, manual data entry, and “firefighting” mode, these disruptions aren’t just headaches. They’re costly: delayed shipments erode customer trust, missed regulatory updates trigger fines, and last-minute reroutes inflate logistics costs.

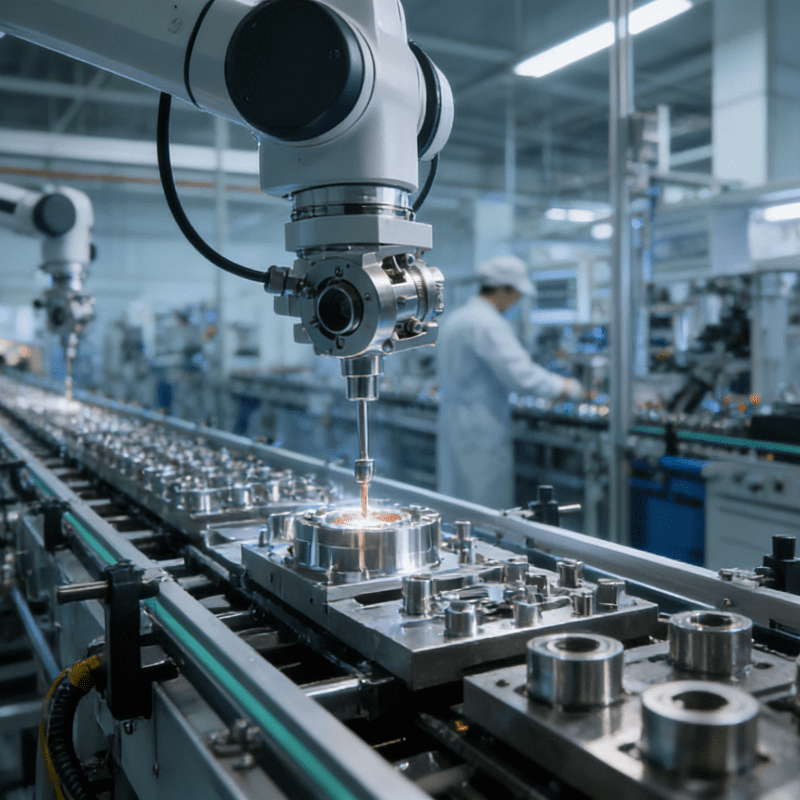

But imagine a system that sees these disruptions coming. It scans policy feeds for tariff changes, tracks port delays in real time, and even parses dense legal documents to flag new rules. Then, it acts—updating duty calculations, rerouting cargo, or adjusting compliance forms—before your team even opens their inboxes. This isn’t science fiction. It’s intelligent automation: the combination of AI (to “see” and “learn”) and RPA (to “act” and “execute”) that’s turning reactive supply chains into proactive ones.

The Growing Chaos of Global Trade

Global trade has always been complex, but today’s disruptions are faster and more unpredictable than ever. A port strike in Los Angeles can delay shipments to Europe. A sudden tariff hike in Southeast Asia can upend pricing models overnight. New customs rules from the EU or China—often released with little warning—force companies to rewrite compliance playbooks on the fly.

It’s not just logistics. Political instability, currency swings, and trade sanctions add layers of risk. A supplier in a newly sanctioned country can cut off a critical part of the supply chain. A regulatory update in Brazil might require new documentation for agricultural exports, with penalties for noncompliance starting in 48 hours.

Manual processes stand no chance. Teams spend 40% of their time chasing data across emails, spreadsheets, and outdated systems—time that vanishes when a disruption hits. A single delay ripples outward: production pauses, customers complain, and costs spiral. To survive, companies need more than speed—they need systems that can anticipate and adapt without waiting for human input.

Intelligent Automation: From “React” to “Predict”

Intelligent automation isn’t just “faster software.” It’s a combination of two technologies working in sync:

AIacts as the “brain”: It scans global trade data (policy updates, port statuses, weather alerts), learns patterns, and identifies risks before they escalate.

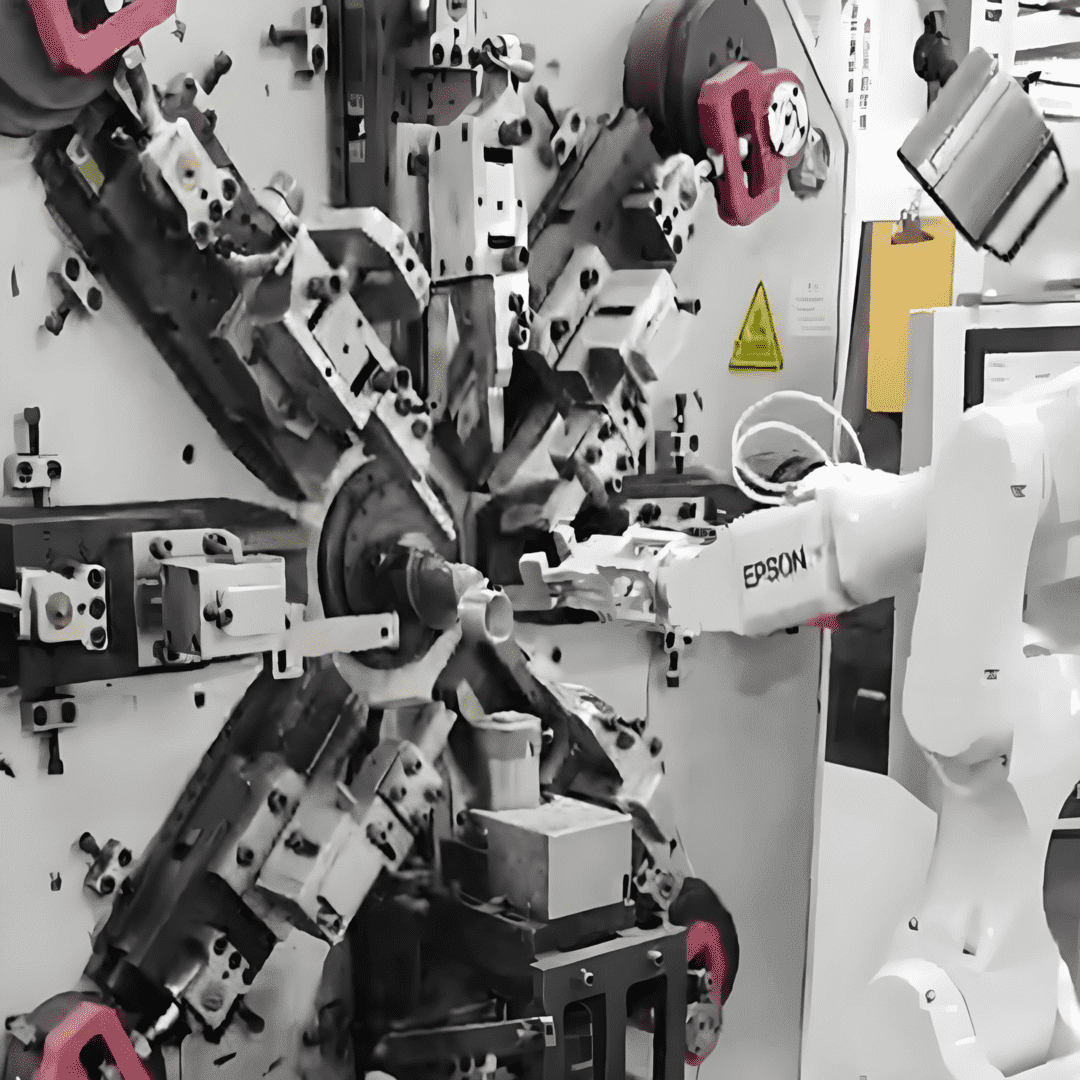

RPA (Robotic Process Automation)acts as the “hands”: It executes repetitive tasks—updating spreadsheets, submitting forms, adjusting shipping schedules—with zero errors, 24/7.

Together, they turn “chaos” into “control.” For example:

When a new tariff is announced, AI flags the change and maps which products are affected. RPA then updates pricing models, adjusts invoices, and alerts sales teams—all in minutes, not days.

If a port is shut down by a storm, AI analyzes alternative routes (cost, speed, reliability) and recommends the best option. RPA updates shipping manifests, notifies carriers, and shares revised timelines with customers automatically.

When a country tightens customs rules, AI parses the legal jargon to identify required document changes. RPA revises templates, submits test filings to check compliance, and logs every step for audits.

This isn’t just efficiency—it’s resilience. Disruptions still happen, but they no longer derail operations.

Three Critical Ways Automation Navigates Disruptions

1. Adapting to Volatile Trade Policies

Trade policies shift overnight, but manual tracking leaves companies playing catch-up. A tariff hike might go unnoticed for days; a rule change could result in misclassified shipments and fines.

Intelligent automation closes this gap. AI monitors 24/7 feeds from customs agencies, trade bodies, and news sources, flagging policy shifts the moment they’re announced. It even interprets “fine print”—like exceptions for certain product categories—to avoid overreacting. RPA then updates internal systems: duty rates, product classifications, and compliance checklists are adjusted automatically. Teams skip the “scramble” and focus on strategy, knowing policies are always up to date.

2. Streamlining Compliance in a Maze of Rules

Regulations now come from dozens of countries, each with unique requirements. A cosmetic exporter might face labeling rules from the FDA, EU Cosmetics Regulation, and China’s NMPA—all changing at different paces. Manual compliance means endless cross-checking, missed steps, and costly fines.

Automation simplifies this. AI acts as a “regulatory translator”: It reviews new rules, maps them to your products, and highlights what needs to change (e.g., “China now requires batch-test reports for skincare”). RPA then updates compliance checklists, triggers document collection from suppliers, and submits filings. Every action is logged, making audits a breeze. Compliance stops being a “risk” and becomes a “given.”

3. Keeping Cross-Border Logistics Moving

Delays, container shortages, and bottlenecks are now routine. A single holdup at a key port can delay shipments across continents—unless you can reroute fast.

Automation turns “delays” into “detours.” AI pulls live data from carriers, ports, and logistics partners to track shipments in real time. It spots red flags early: a container stuck in customs, a trucking shortage at a hub, a sudden spike in fuel prices. It then recommends alternatives—e.g., “Switch from sea to air for urgent orders; use a secondary port for bulk cargo”—and ranks them by cost and reliability. RPA executes the chosen plan: updating schedules, notifying all stakeholders, and even renegotiating carrier contracts if needed.

The result? Logistics stays agile, even when the world doesn’t.

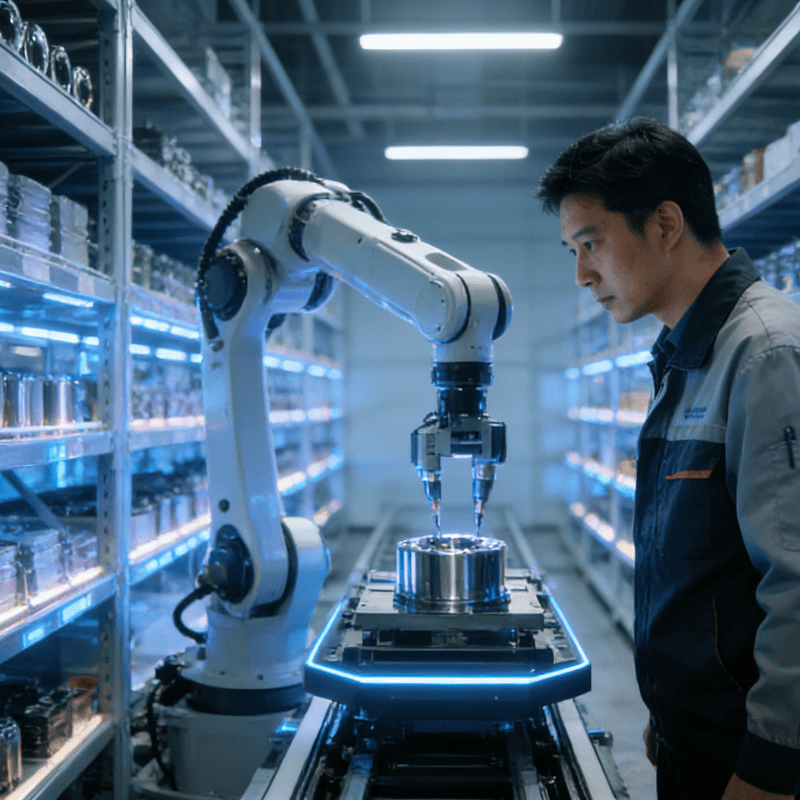

Humans + Machines: The Real Secret to Resilience

Automation doesn’t replace people—it elevates them. When AI and RPA handle repetitive tasks (data entry, policy tracking, form submissions), teams are freed to focus on work that needs human judgment: negotiating with suppliers, building relationships with customs officials, or designing long-term trade strategies.

For example, instead of spending 10 hours a day updating shipping spreadsheets, a logistics manager can analyze AI-generated reports to spot trends (“This port is consistently delayed—should we shift to a new carrier?”) and build more resilient supply chains. Instead of parsing legal texts, a compliance specialist can collaborate with global teams to design flexible processes that adapt to any rule change.

This “human + machine” synergy turns “surviving” into “thriving.” Companies don’t just weather disruptions—they use them to gain an edge.

Getting Started: From Pilot to Resilience

Adopting intelligent automation doesn’t require a complete overhaul. Start small, then scale:

Pick a pain point: Focus on one high-impact area—e.g., “We always miss tariff updates” or “Port delays catch us off guard.”

Run a pilot: Test AI + RPA on that single process. Track metrics (time saved, errors reduced, disruptions avoided) to prove value.

Involve your team: Train them to work withthe tools—e.g., how to interpret AI risk alerts or adjust RPA workflows for new scenarios. Their buy-in makes scaling possible.

Expand strategically: Once the pilot works, apply the same model to related processes (e.g., from tariff tracking to customs compliance).

Global trade will always be unpredictable. New disruptions—policies, weather, geopolitics—will keep emerging. But with intelligent automation, companies don’t have to be victims of chaos. They can turn disruptions into opportunities: responding faster than competitors, avoiding costly mistakes, and building supply chains that are not just efficient, but resilient.

The question isn’t “Will the next disruption hit?” It’s “Will you be ready when it does?” Intelligent automation ensures the answer is “Yes.”