Table of Contents

ToggleHow AI-Powered Data Automation Drives Intelligent Automation in Supply Chains

In an era where intelligent automation and industrial automation are reshaping global logistics, supply chains face a paradox: the more interconnected they become, the harder it is to manage fragmented data. AI-powered solutions are emerging not just as tools, but as essential automation equipment to transform chaotic data flows into streamlined, actionable insights. Here’s how they solve the foundational challenges holding back supply chain resilience.

The Data Quagmire: Why Traditional Systems Fail

Modern supply chains are data powerhouses, generating terabytes from suppliers, logistics partners, and IoT devices. Yet, 80% of this data remains unstructured—trapped in PDFs, emails, and legacy systems, according to IBM. This fragmentation creates:

- Blind Spots: Siloed data (e.g., inventory in Excel, shipments in ERP systems) leaves planners guessing at real-time demand.

- Manual Bottlenecks: McKinsey notes companies with poor data management lag 7.5% in revenue growth, often stuck reconciling spreadsheets instead of strategizing.

- Onboarding Gridlock: Adding a new supplier can take weeks due to incompatible data formats, a critical flaw in an era of industrial automationwhere agility is king.

At the heart of these issues is the “first-mile data problem”—the chaotic ingestion of unstandardized data from partners. Each invoice, PO, or shipment update arrives in a unique format, requiring manual labor to parse—a process as inefficient as using a wrench for a screwdriver in a factory of automation equipment.

AI-Powered Solutions: The New Standard for Intelligent Automation

AI transforms this chaos into a well-oiled machine, integrating automation equipment principles into data workflows:

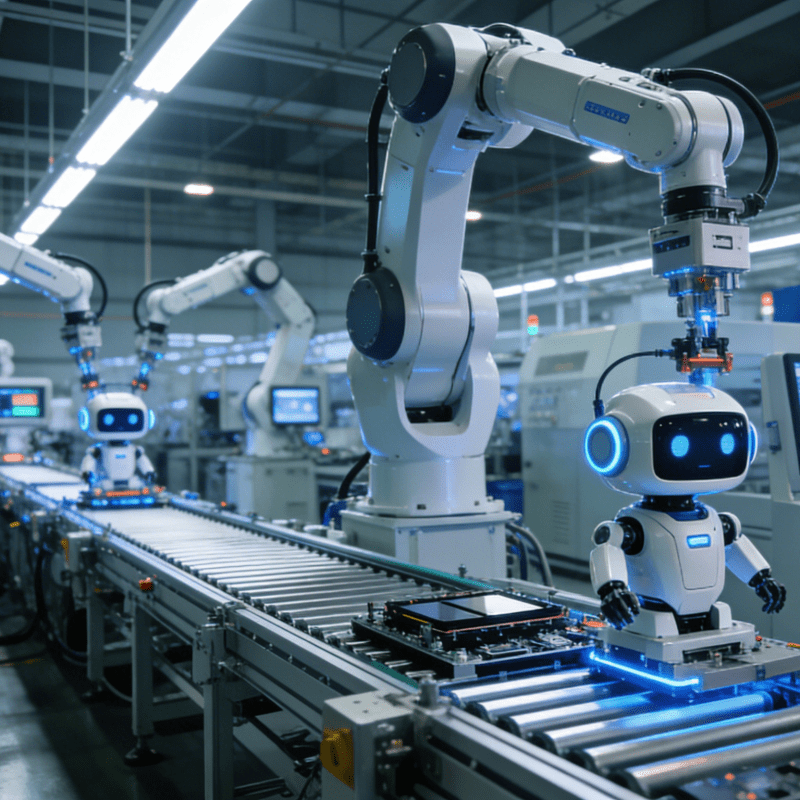

Document Processing as Digital Assembly Lines

AI-driven tools like OCR and NLP act as automation equipment for paperwork, extracting data from invoices, bills of lading, and emails with 80% less manual effort (APQC). For example, a global manufacturer cut invoice processing from days to minutes by automating data extraction, turning error-prone manual entry into a digital assembly line.

Self-Service Tools for Supply Chain Engineers

Modern platforms empower supply chain teams to design data pipelines without IT support—a “DIY” approach to intelligent automation. Gartner reports this slashes supplier onboarding from weeks to days, much like retooling a factory line without waiting for engineers. A retail distributor used this to rapidly expand its supplier network during disruptions, proving agility is as much about data speed as physical logistics.

Predictive Quality Control for Data

AI models monitor data flows in real time, acting as quality control inspectors in a factory. They flag anomalies—like a sudden spike in delivery delays or mismatched SKUs—before they cascade into crises. A logistics provider used this to improve delivery prediction accuracy by 30%, reducing customer complaints and optimizing route planning.

Real-Time Automation: The Brain of Modern Supply Chains

Replacing overnight batch processing, AI enables instant responses to disruptions—think rerouting trucks mid-trip due to weather data or adjusting production schedules based on real-time supplier updates. This is intelligent automation in action: data isn’t just observed; it’s used to automate decisions, much like a factory’s PLC system adjusting to machine sensor data.

From Data to Dominance: Real-World Wins

- Manufacturing: A automotive parts supplier used AI to standardize data from 500+ suppliers, cutting onboarding time by 60% and enabling just-in-time inventory models.

- Retail: A global brand automated 90% of its PO processing, freeing buyers to focus on strategic vendor relationships instead of data entry.

- Logistics: A 3PL provider implemented real-time data dashboards, reducing delivery delays by 25% through AI-driven route optimization—proof that automation equipmentfor data is as critical as forklifts and conveyor belts.

Building Your Data-Driven Supply Chain

- Map Your Data Factory: Identify bottlenecks (e.g., manual invoice processing, siloed IoT data) where AI can act as automation equipment.

- Start Small, Scale Smart: Pilot AI on high-volume, low-complexity tasks (e.g., receipt scanning) to prove ROI before scaling to strategic workflows.

- Train Your Team as Data Engineers: Equip planners with self-service tools to design AI workflows, mirroring how factory workers operate advanced machinery.

- Future-Proof with Scalable Architecture: Choose solutions that grow with your supply chain, whether adding new regions, partners, or industrial automation

Closing: The AI-Driven Supply Chain as a Smart Factory

In the end, supply chains are no different from factories: both thrive on efficient, error-free workflows. AI-powered data automation is the intelligent automation layer that turns raw data into the “digital oil” of modern logistics—refined, standardized, and ready to fuel decisions. By treating data as a core component of automation equipment, companies aren’t just solving challenges; they’re building supply chains that anticipate disruptions, optimize in real time, and deliver on the promise of a connected, resilient future.

As global markets grow more complex, remember: the best AI in the world is only as good as the data it consumes. Invest in data automation today, and let your supply chain operate not just faster, but smarter.