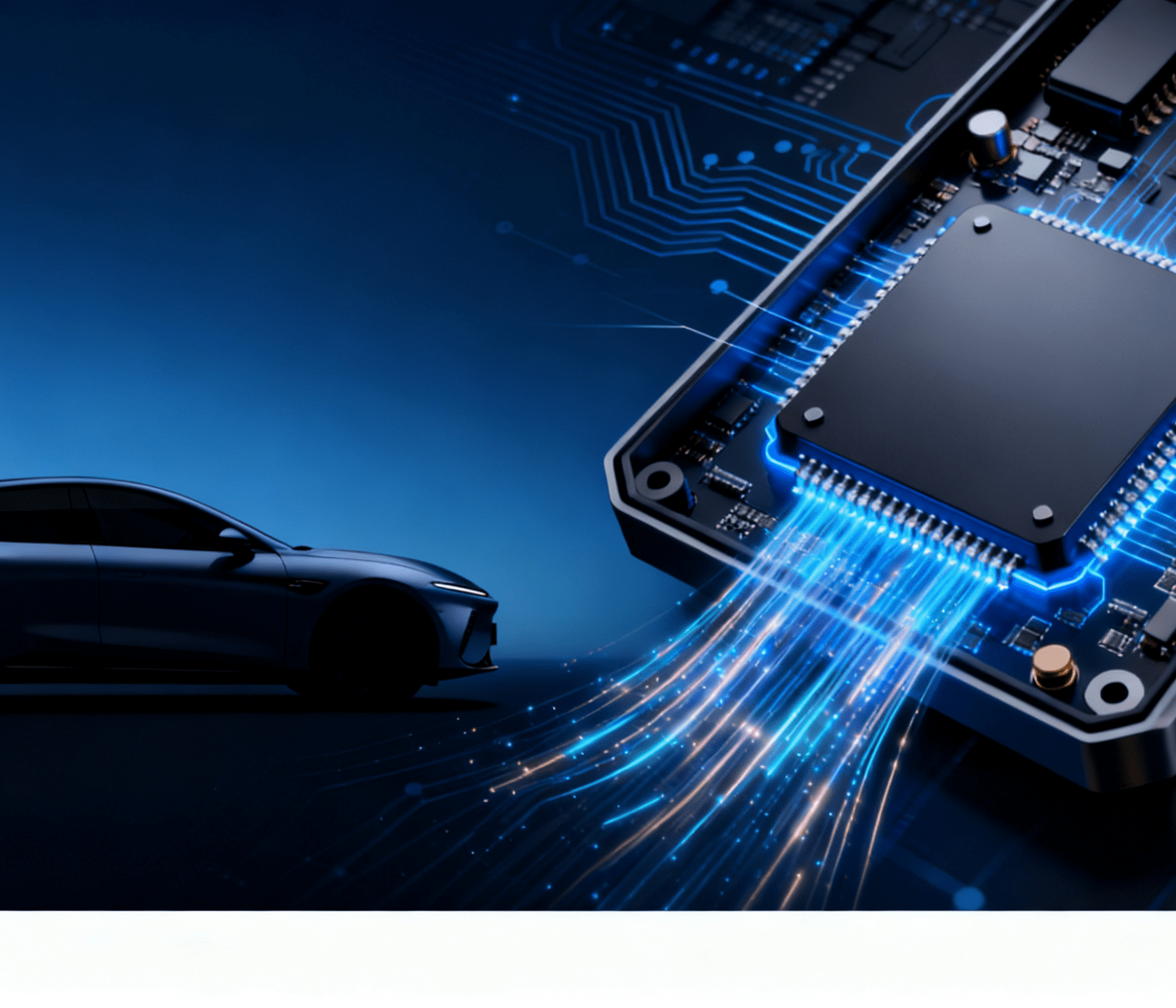

As the core fulcrum of Honda’s electrification transformation, its electric vehicle center in Ohio is reshaping the flexibility and sustainability of automobile manufacturing with an investment of over $1 billion. Through the comprehensive renovation of the Marysville Auto Plant (MAP), East Liberty Auto Plant (ELP), and Anna Engine Plant (AEP), the center will achieve industry-leading flexible production capabilities — seamlessly switching between the production of internal combustion engine (ICE) vehicles, hybrid vehicles, and pure electric vehicles (EVs) on the same production line. This not only allows rapid responses to fluctuations in market demand but also reserves sufficient flexibility for the future full electrification transition. This layout is not only a key step for Honda to fulfill its commitment of “100% zero-emission vehicles by 2040” but also marks its leap from traditional manufacturing to “human-centered, eco-friendly” intelligent production.

The first mass-produced model at the center will be the all-new Acura RSX SUV, rolling off the production line by the end of 2025, followed by mass-produced versions based on the Honda 0 Series Saloon and 0 Series SUV prototypes unveiled at the 2025 CES. Notably, the Honda 0 Series models will be equipped with the original vehicle operating system ASIMO OS — a name that pays tribute to Honda’s iconic ASIMO robot while highlighting the 0 Series’ core positioning of “intelligent mobility,” delivering a more intelligent interactive experience for users. Simultaneously advancing is the joint venture LH Battery Plant with LG Energy Solution, with a total investment of $4.4 billion and a planned annual capacity of 40 GWh. This will provide stable core energy support for the electric vehicle center, forming a localized production closed loop of “vehicle + battery.”

Beyond manufacturing innovation, the Honda Electric Vehicle Center adheres to the “Triple Action towards Zero Emissions” strategy, integrating sustainable development throughout the entire production chain. In the field of carbon neutrality, the high-efficiency furnaces introduced at AEP can reduce natural gas consumption and can be upgraded to plasma arc melting technology in the future; energy-saving HVAC and lighting equipment replaced across the entire plant continuously reduce the carbon footprint. In terms of clean energy, through long-term virtual power purchase agreements (VPPAs), Honda’s North American manufacturing operations already source over 60% of their electricity from renewable wind and solar energy, with the goal of achieving 100% carbon-free energy usage. In resource recycling, every link — from on-site recycling and melting of aluminum at AEP for battery case manufacturing to converting employee uniforms into automotive sound-absorbing and thermal insulation materials — fulfills the commitment of “full utilization of sustainable materials.”

From technological breakthroughs in flexible production to environmental practices throughout the entire life cycle, the Honda Electric Vehicle Center is not just a manufacturing base but also a concrete carrier of its vision of “zero environmental impact by 2050.” The electrified production knowledge and technologies accumulated here will radiate through North American and global factory networks, providing the industry with a manufacturing model of “flexible response and green sustainability.” When the first Acura RSX SUV rolls off the production line at the end of 2025, what we will witness is not just the birth of a new car, but a solid step forward for the automotive industry towards an intelligent, low-carbon future.

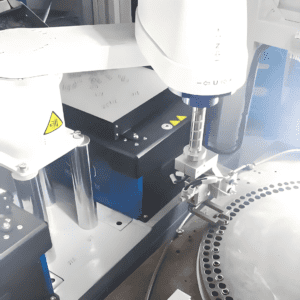

Flexible production automobile parts assembly machine

Workflow of automobile contactor assembly machine