On October 20, at the IROS2025 · Meituan Robot Research Institute Academic Annual Conference—an official sub-forum of IROS2025 in Hangzhou—Li Yifan, CEO of Hesai Technology, delivered a speech titled InfraForPhysicalAI: Changes and Constants from Automobiles to Robots.

Robot 1.0 vs. Physical AI 2.0: Core Differences Between Industries

When talking about the robot industry, Li Yifan argued that the fundamental difference between the robot industry and the automotive industry lies in two key aspects: automobiles are “Robot 1.0″—mature in hardware but non-interactive with the environment, with safety as their core requirement; whereas embodied intelligent robots represent “Physical AI 2.0,” whose core lies in interaction. Most robots are autonomous systems that interact with the environment, making them “native AI products” compared to automobiles.

The Hardware-Data Dilemma: A Core Challenge for Embodied Intelligence

However, embodied intelligent robots currently face challenges such as low hardware maturity, lack of massive datasets, and difficulty in decoupling hardware and software.

“The amount of data generated by robots today is likely four to five orders of magnitude less than that from automobiles or public online data—and this remains an unsolved problem,” Li noted. To address this issue, he emphasized that only with high-quality hardware can robots generate high-quality data.

Additionally, Li Yifan believes that decoupling hardware and software in the robot industry may be unachievable. Currently, precisely because hardware and software are not decoupled, more opportunities emerge for players to prioritize hardware excellence as an entry point for data acquisition.

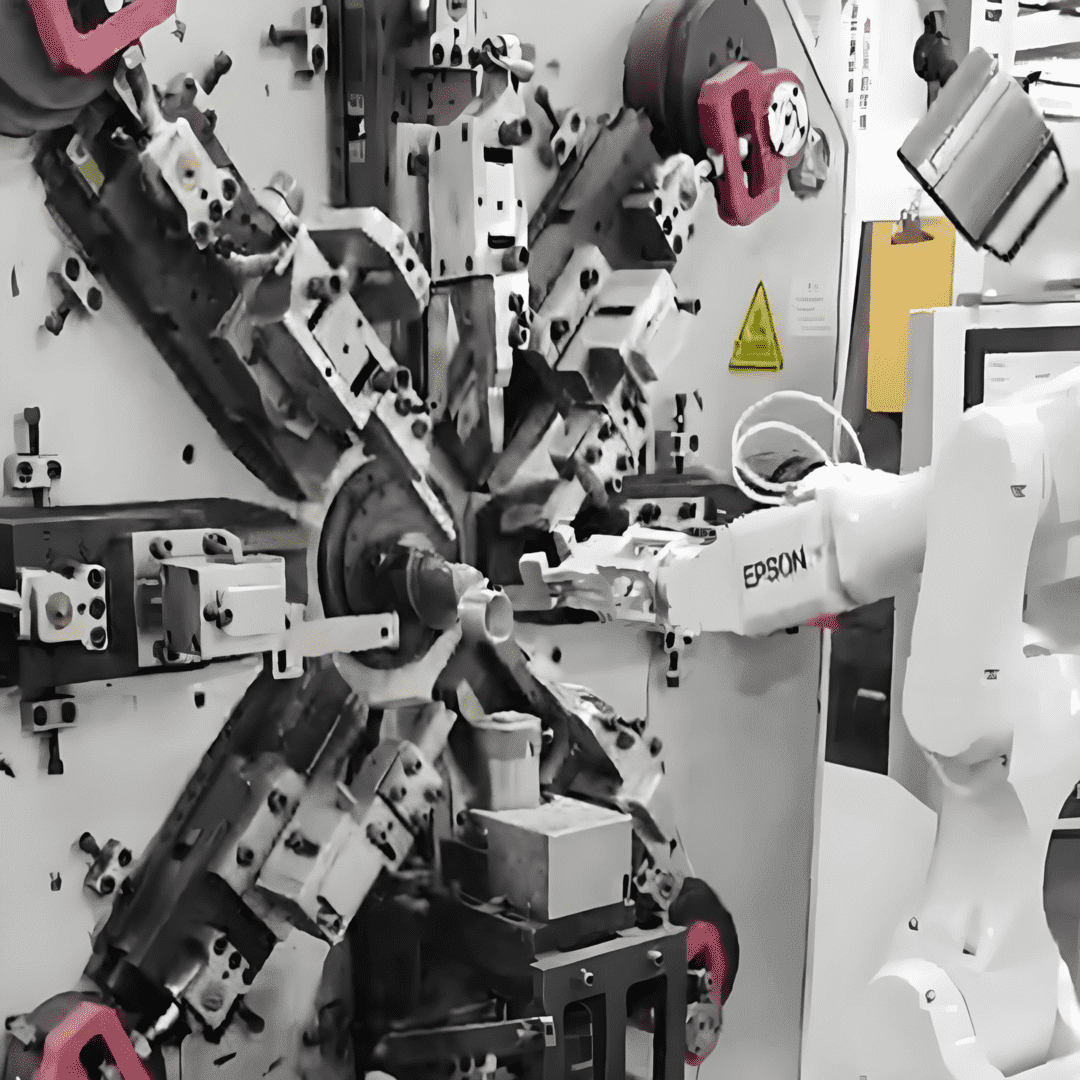

China’s Competitive Edge: Opportunities in Hardware-Software Integration

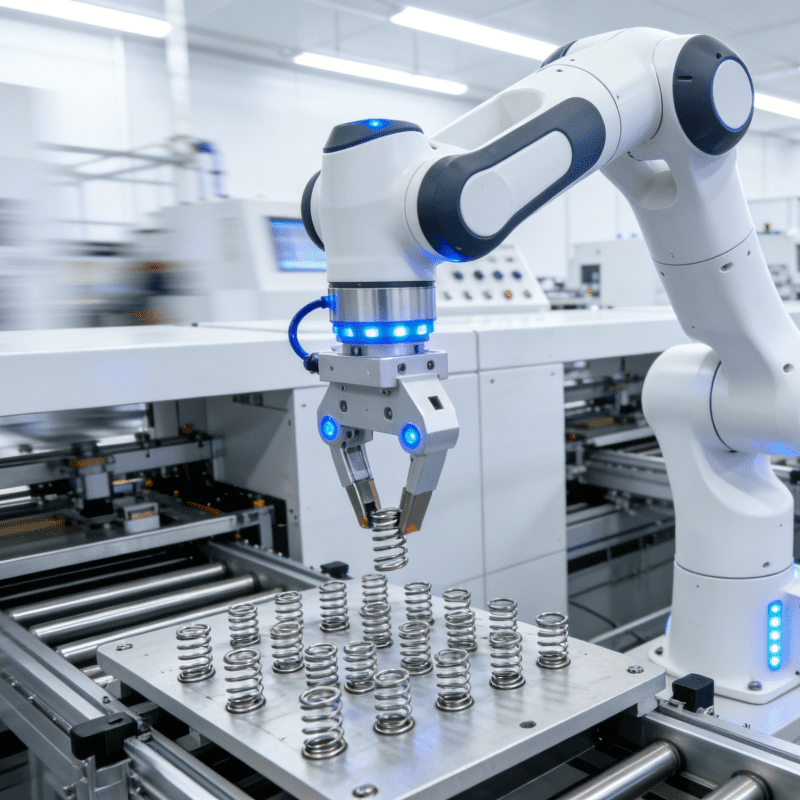

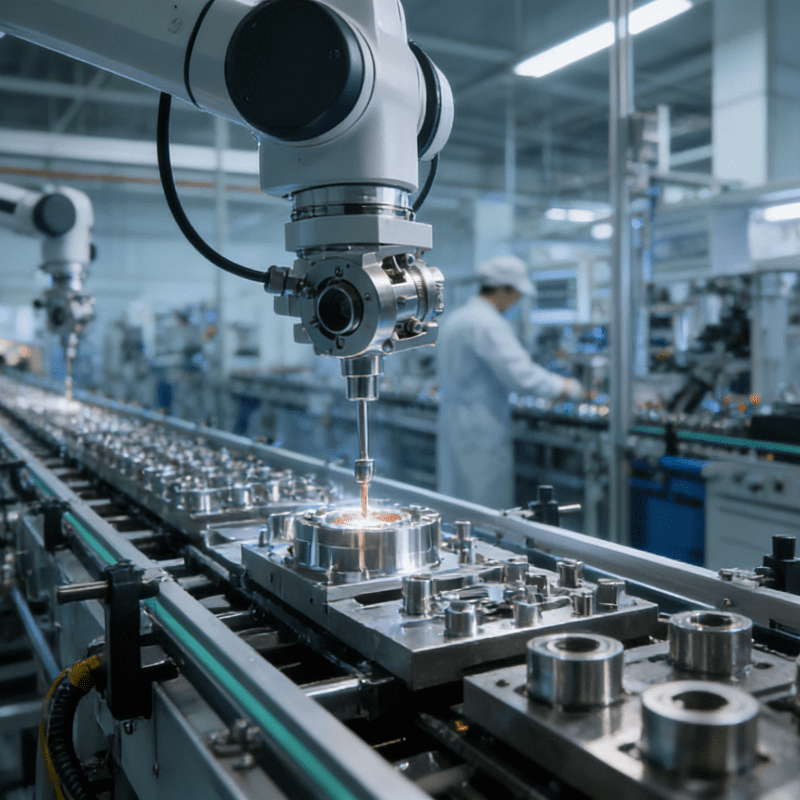

Li pointed out that various components in the robot industry—whether perceptual infrastructure like tactile sensors, dexterous hands, complete robot bodies, or even products integrated with LiDAR-based perception capabilities—will be more critical than their counterparts in the automotive industry. This importance of hardware is equally evident in industrial automation scenarios: for example, in fuse assembly machines (a key piece of equipment in electronic component manufacturing), the precision of hardware modules such as servo-driven positioning systems, vision-guided alignment sensors, and pressure-controlled assembly arms directly determines the quality of production data. Similarly, in automatic quick-connect parts assembly machines—vital for efficient manufacturing of automotive and aerospace components—hardware performance in areas like microsecond-level response actuators, multi-axis force feedback sensors, and adaptive clamping mechanisms dictates the richness of data captured during high-speed assembly. Only machines with such high-caliber hardware can record nuanced metrics: connection insertion depth accuracy, real-time torque adjustments, and inter-part contact pressure distribution—data that drives AI-driven process optimization, reduces rework rates, and ensures consistency in mass production.

This real-world application further confirms that high-quality hardware is the prerequisite for generating high-value data in embodied intelligence. This hardware-software interdependence presents enormous opportunities for Chinese entrepreneurs: in the track where hardware and software are closely integrated, China’s strong supply chain (covering precision machining, sensor manufacturing, and industrial control systems) and mature manufacturing capabilities enable the rapid iteration and cost-effective production of high-performance robotic hardware—from core components to end-use equipment like fuse assembly machines and automatic quick-connect parts assembly machines. “This could be the best opportunity we see in the next 20 years,” Li stated.