For the luxury perfume industry, the perfume cap is not only a protective component but also a key part of brand image. Its assembly quality, such as fitting precision and appearance consistency, directly affects product grade and consumer trust. However, the diverse shapes, materials, and process requirements of high-end perfume caps make standard assembly equipment difficult to meet production needs. Ruizhi Intelligent Manufacturing, a professional non-standard automation solution provider, launches a high-precision custom perfume cap assembly machine, tailored to solve the pain points of high-end perfume packaging assembly.

Industry Pain Points: The Dilemma of High-Precision Assembly for Custom Perfume Caps

High-end perfume caps often feature complex structures, such as irregular shapes, inlaid decorations, and multi-material combinations, posing severe challenges to assembly. Manual assembly is prone to errors like uneven fitting and scratches, with a defect rate exceeding 3%. Standard assembly machines have fixed structures, unable to adapt to custom specifications, and their assembly precision (around ±0.05mm) cannot meet the leak-proof and aesthetic requirements of luxury perfumes. Moreover, switching between different custom cap models requires lengthy tooling adjustments, seriously affecting production efficiency. These pain points have become a bottleneck restricting the development of high-end perfume brands.

Core Advantages: Ruizhi’s High-Precision Custom Assembly Solutions

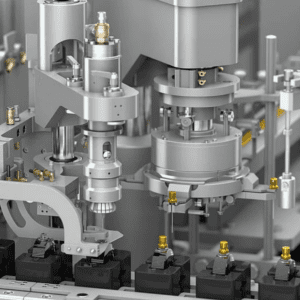

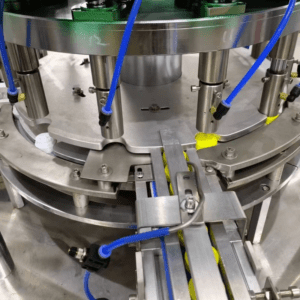

Ruizhi’s high-precision custom perfume cap assembly machine achieves a qualitative leap in assembly quality and efficiency through targeted design. Firstly, ultra-high precision guarantee: Equipped with advanced visual positioning and servo control systems, the assembly precision reaches ±0.001mm, ensuring tight fitting of caps and bottles, with a leak-proof rate of 99.8% and a defect rate below 0.2%. Secondly, flexible customization capability: It can be tailored according to cap materials (glass, metal, plastic), shapes (circular, square, irregular), and process requirements (inlay, engraving), completing model switching in 15 minutes. Thirdly, intelligent process integration: Integrating automatic feeding, precision assembly, appearance inspection, and packaging, it reduces manual intervention and ensures consistent product quality.

Practical Value: Empowering High-End Perfume Brands to Upgrade Production

Ruizhi’s high-precision custom assembly machine has been widely recognized in practical applications. A well-known luxury perfume brand once struggled with high defect rates and low efficiency in custom cap assembly. After adopting Ruizhi’s customized assembly line, the defect rate dropped from 3.2% to 0.15%, production efficiency increased by 42%, and the consistent appearance of products enhanced the brand’s premium image. Additionally, Ruizhi provides one-stop services from demand communication, scheme design, to after-sales maintenance, ensuring the stable operation of equipment. This full-chain support helps enterprises reduce operation risks and realize cost reduction and efficiency increase.

In the fierce competition of the luxury perfume market, high-quality packaging assembly is an important core competitiveness. Ruizhi Intelligent Manufacturing’s high-precision custom perfume cap assembly machine, with its professional customization capability and reliable precision performance, provides a strong guarantee for high-end perfume brands to improve product quality and expand market share. Choosing Ruizhi is choosing a customized path to intelligent upgrading of perfume packaging assembly.