In modern manufacturing, CNC (Computer Numerical Control) machining, as an advanced production method, is gaining increasing popularity among enterprises. CNC machining refers to the process of precisely controlling machine tools through computer programs to perform cutting, milling and other operations, aiming to improve production efficiency and product quality. As we can see, this machining method is widely applied in multiple fields such as aerospace, automotive manufacturing and medical devices. In these industries, the dimensional accuracy and surface quality of parts directly affect the performance and safety of the final products, making CNC machining particularly crucial.

With the development of science and technology, CNC machining is not limited to simple mechanical operations; it can also process complex geometric shapes and high-hardness materials. Through reasonable software programming and machine tool configuration, we can efficiently manufacture various types of components. Meanwhile, many enterprises have realized that the application of CNC technology can effectively reduce labor costs and improve work efficiency. Therefore, a growing number of traditional manual processing enterprises have begun to transform to CNC machining.

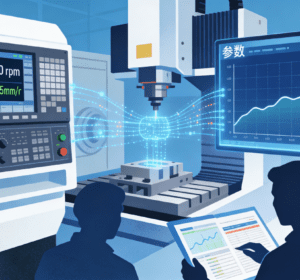

In practical operation, we find that data collection and monitoring during the CNC machining process are equally indispensable. Real-time monitoring of key production parameters (such as cutting speed and feed rate) enables the timely detection of potential problems and implementation of adjustments, thus ensuring that the finished products meet specified standards. Overall, when exploring the basic concepts and application scenarios of CNC machining, we should not only recognize its technical advantages but also focus on how to effectively utilize these advantages to boost productivity.

An Analysis of the Importance of High-Precision CNC Machining

In modern manufacturing, the importance of high-precision CNC machining is self-evident. We are living in a highly competitive market environment where product quality directly impacts an enterprise’s competitiveness. High-precision CNC machining can not only improve the machining accuracy of products but also help enhance production efficiency and reduce material waste, thereby effectively controlling production costs. In addition, many high-value-added industries, such as aerospace and medical devices, impose extremely stringent requirements on the dimensional accuracy and surface quality of components. Even minor errors may lead to serious consequences. Therefore, ensuring precision control during the CNC machining process is of vital importance.

We should also note that high-precision CNC machining can deliver better product consistency. In mass production, maintaining consistency among products is especially critical, as it is closely related to customer satisfaction and brand reputation. With the help of efficient and stable CNC machining technology, we can achieve consistent quality for products in the same batch, which is an indispensable factor for enhancing enterprise credibility.

Furthermore, we cannot ignore the role of high-precision CNC machining in technological innovation and research and development. As technology advances, new materials and processes emerge continuously, and we must have the ability to process more complex parts. Through high-precision CNC machining, we can explore the application of higher-performance materials and the realization of complex shapes, thereby helping enterprises gain a leading position in the market. In conclusion, high-precision CNC machining is not only an important means to improve efficiency and ensure quality but also a key driver for the sustainable progress and innovative development of the manufacturing industry.

Key Elements of CNC Machining Processes

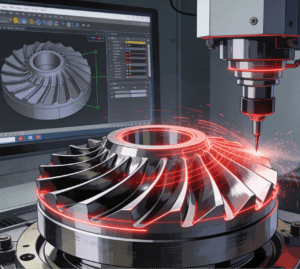

In high-precision CNC machining, precision control and measurement technology are core elements that cannot be overlooked. First of all, precision control requires the establishment of strict standards and specifications throughout the entire machining process. We usually adopt high-precision CNC machine tools and cutting tools, which can not only ensure that the shape and size of components meet expected requirements but also optimize cutting speed and tool service life. In addition, we tend to select sensors with accurate positioning capabilities to achieve real-time monitoring and feedback, so as to adjust machining parameters in a timely manner and ensure that precision is always within a controllable range.

Secondly, measurement technology is equally important. We usually use advanced equipment such as laser detection devices and coordinate measuring machines for online or offline inspection. These devices can quickly and accurately conduct dimensional and geometric tolerance analysis of workpieces, helping us identify the causes of non-compliance and further adjust the production process. This link not only improves product consistency but also provides strong data support for subsequent quality control.

In practical operation, we also attach great importance to CNC programming and process parameter setting, which are crucial for achieving high-precision results. Accurate software programming can effectively reduce the impact of human operational errors on product quality. Moreover, the integration of automated auxiliary systems further elevates process stability—for example, in batch machining of auto parts or mechanical components that require circlip assembly, equipping the CNC machining line with an Automatic Circlip Feeding System can realize high-precision automatic feeding of circlips. This system avoids manual feeding errors, synchronizes feeding rhythm with CNC machining speed, shortens auxiliary time between processes, and ensures consistent positioning accuracy of circlips during assembly, directly improving the pass rate of finished products. Therefore, strengthening the training of processing personnel and improving their understanding and application ability of precision control, measurement technology and automated auxiliary systems will help promote the overall production efficiency and quality level. In this process, we continuously explore innovation and optimization to gain a foothold in the increasingly fierce market competition.

Key Points for the Selection and Configuration of CNC Machining Centers

In high-precision CNC machining, we must attach importance to the selection and configuration of CNC machining centers, as this directly affects machining efficiency and product quality. First of all, when selecting a suitable CNC machining center, we need to consider its accuracy grade. High-precision equipment can ensure tolerance control during product processing, thereby improving the consistency and reliability of the final products. In addition, the structural design of the machining center is also a key factor that cannot be ignored. We should prioritize equipment with a robust structure and high rigidity, which can effectively reduce vibration generated during high-speed cutting and improve the stability of the machining process.

Secondly, the control system of the machining center is also one of our concerns. Modern CNC systems are equipped with more efficient and intelligent software, which can improve programming efficiency and shorten setup time. Moreover, equipment with self-detection and correction functions can conduct real-time error monitoring during operation and make automatic adjustments, thus ensuring higher precision in the CNC machining process.

Finally, we should also pay attention to the specific processing requirements of different workpiece materials. For example, for some materials hardened by heat treatment, we may need to configure special quick-change tools to cope with higher cutting forces and wear, so as to ensure that the tools are durable and maintain good machining results. Against the backdrop of continuous technological progress and upgrading, the rational selection and configuration of CNC machining centers are crucial for improving our overall production capacity. In this way, we can achieve more efficient, stable and high-quality production results.