High-precision CNC (Computer Numerical Control) machining technology leverages digital control systems to operate high-precision machine tools, enabling the processing of parts with precision ranging from micrometers (μm) to sub-micrometers. It encompasses processes such as automotive component machining, cutting, and electrical discharge machining (EDM). Technological advancements in this field focus on three key areas: enhancing precision, improving processing efficiency, and expanding capabilities for machining complex structures. Driven by innovations like 5-axis machining technology, nano-positioning systems, and intelligent programming algorithms, the precision machining industry is transitioning from single-process precision optimization to full-process intelligent upgrading.

Contemporary high-precision CNC machine tools have evolved from basic programming to full-process simulation. By integrating high-precision servo motors and thermal deformation compensation technology, they minimize errors caused by human factors, providing technical support for fields with stringent precision requirements such as aerospace engineering, medical equipment, and semiconductors.

Multidimensional Impacts of Key Technological Improvements on the Industry

Subversive Enhancement of Dimensional Precision and Stability

Traditional CNC machining precision is subject to a certain range of fluctuations. The new generation of high-precision CNC machine tools has achieved breakthroughs through multi-faceted technological innovations:

Improved multi-axis machining precision: Advanced linkage error compensation algorithms elevate the machining precision of complex spatial surfaces to a higher level, meeting the precision forming requirements of components such as aero-engine blades.

Nano-positioning technology: The combination of magnetic levitation guideways and laser interferometer feedback enables the production of semiconductor wafer cutting dies with high resolution and strong dimensional precision for machine tool feed axes.

Dynamic error compensation: Based on the distribution of sensors on each axis of the machine tool, errors caused by thermal deformation and vibration are adjusted in real time, solving the problem of precision fluctuations in batch processing during traditional machining.

Such precision improvements drive the upgrading of precision parts from merely meeting basic requirements to enhancing overall performance. For example, optimizing the dimensional precision of rollers in precision bearings significantly extends their service life and reduces operational noise.

Leapfrog Development in Productivity and Automation

Through innovations in hardware and software, the efficiency of high-precision CNC technology has been enhanced:

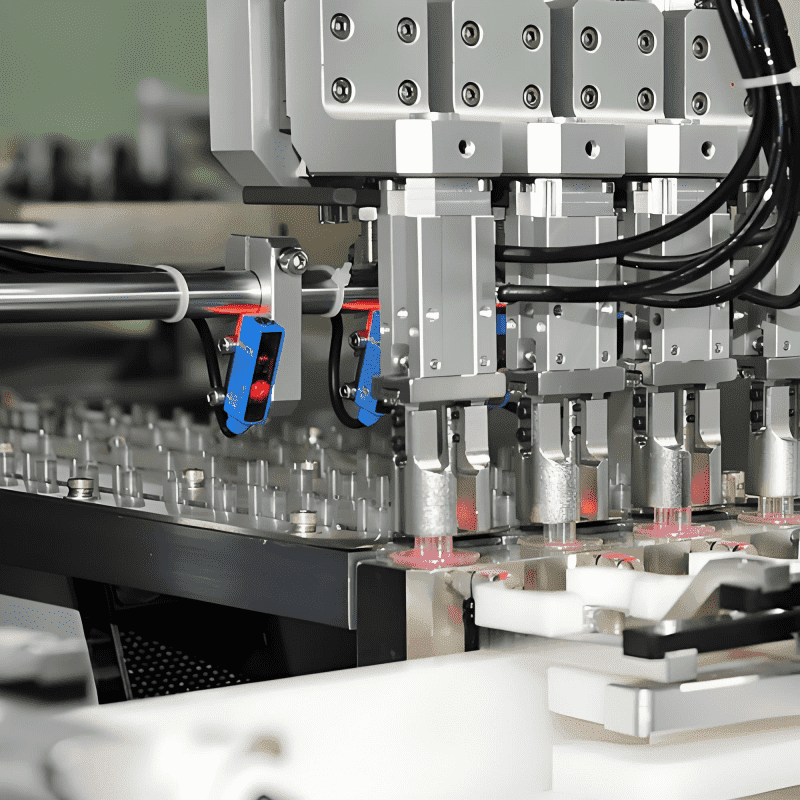

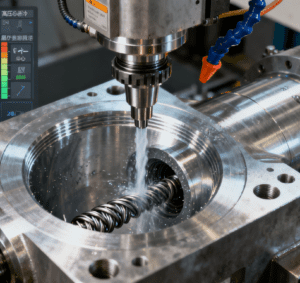

Hardware: High-speed machining spindles combined with advanced drive technology significantly improve the processing efficiency of materials such as aluminum alloys. Among automated hardware solutions, the Sheet automatic loading robot plays a key role in batch processing of plate-like workpieces—equipped with 3D visual positioning and servo-driven clamping mechanisms, it can automatically identify, grab, and position sheet materials (such as titanium alloy plates for aerospace and aluminum alloy sheets for automotive covers) onto CNC machine tool worktables. It achieves an loading precision of ±0.05 mm, reduces manual handling intervention by 90%, and shortens auxiliary time between machining batches by over 30%. Together with automatic loading/unloading systems and machine tool networking technology, it enables long-term unmanned machining, greatly increasing equipment utilization.

Software: Programming systems based on optimized algorithms can automatically identify part features and generate optimal machining strategies, significantly improving the efficiency of traditional manual programming. Real-time monitoring systems adjust cutting parameters via sensors during processing, reducing material waste and boosting processing efficiency.

In scenarios of multi-variety, small-batch production, tool systems and modular fixture technology quickly shorten the setup time for individual batches of parts, significantly enhancing flexible manufacturing capabilities.

Expanding Material Processing Boundaries and Process Innovation

High-precision CNC technology provides new solutions for difficult-to-machine materials such as titanium, heat-resistant alloys, and ceramic matrix composites:

Super-hard material processing: High-frequency vibration drilling technology effectively reduces tool wear, enabling efficient and precise machining of aerospace components.

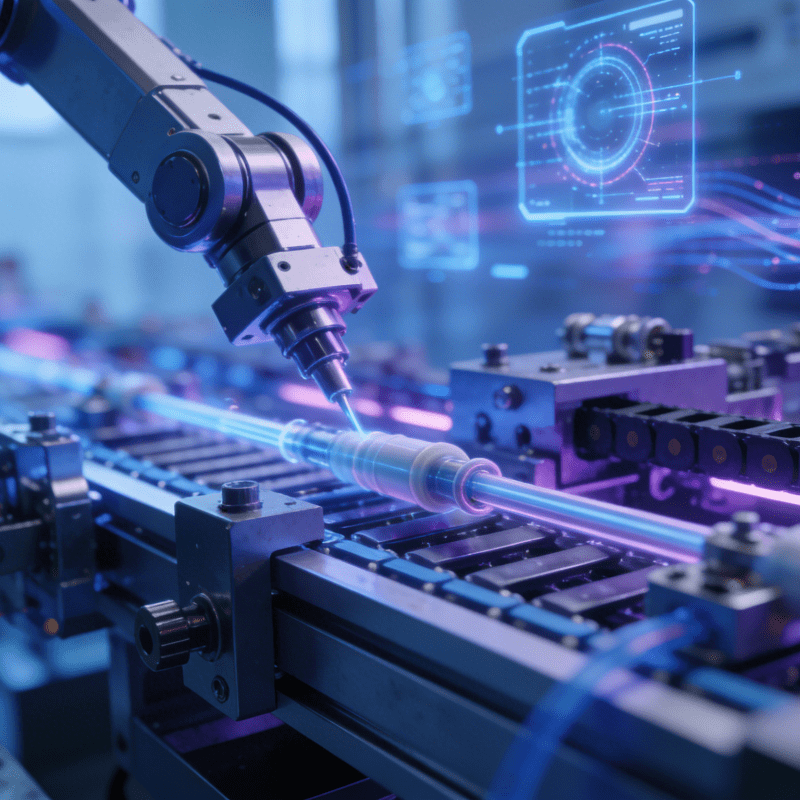

Brittle material forming: Laser-assisted heating CNC machining technology softens materials through localized heating, significantly reducing the occurrence of cracks during processing.

Ultra-thin-walled part processing: Ultra-precision lathes equipped with aerostatic bearings and vacuum suction fixtures can machine ultra-thin-walled parts that meet the miniaturization requirements of medical equipment.

This technological progress has facilitated the transition of numerous high-performance materials from laboratory research to large-scale industrial application, driving the lightweight upgrading of key components in fields such as new energy vehicles.

Innovation in Complex Structure Manufacturing Capabilities and Unleashing Design Flexibility

Traditional machining is limited by the number of machine tool axes and programming capabilities, but new CNC technologies have overcome these constraints:

Micro-nano structure processing: High-precision slow-feeding wire-cut EDM machines can process micro-groove structures required for the manufacturing of MEMS (Micro-Electro-Mechanical Systems) sensors.

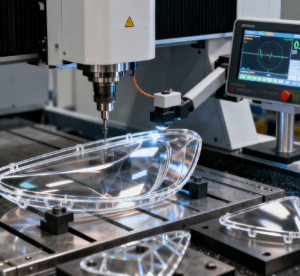

Multi-curvature surface processing: 5-axis machining with advanced tool orientation technology enables precise processing of free-form surfaces (e.g., for automotive lighting components), eliminating the need for traditional manual polishing processes.

Deep-cavity precision processing: Deep-hole drilling machines with extremely high length-to-diameter ratios, combined with high-pressure internal cooling systems, achieve high-precision deep-hole machining of aerospace components.

With these technologies, design engineers can develop more complex integrated designs. For instance, bionically designed porous lightweight parts offer far superior performance compared to traditional structures.

Technology-Driven Industrial Transformation and Future Prospects

Breakthroughs in high-precision CNC machining technology not only improve precision and quality but also reshape the underlying logic of the entire precision machining industry:

Enhanced industrial division of labor: The rise of specialized precision machining service providers drives the industrial chain toward greater specialization.

Accelerated integration of production and design: The emergence of manufacturability analysis tools based on CNC technology significantly shortens product development cycles.

Faster intelligent transformation: The integration of CNC equipment with the Internet of Things (IoT) enables real-time analysis of processing data, shifting production methods from experience-driven to data-driven.

As technologies such as AI algorithms, quantum metrology, and additive manufacturing are integrated, the future of high-precision CNC machining will exhibit trends including consistent high precision, self-optimizing processing processes, and collaborative multi-technology manufacturing. The core of market competition will shift from equipment hardware to the comprehensive capabilities of software, technology, and information. Enterprises must maintain technological iteration and talent development to gain an edge in the high-precision manufacturing field.

Assembly line for mass production by artificial intelligence