Technological Iteration: From Manual to Intelligent, a Paradigm Shift in Packaging

In today’s rapidly developing snack food industry, candies and biscuits, as widely popular categories, continue to see growing production scales and market demand. From manual sorting in traditional workshops to semi-automatic assisted packaging, and now to the widespread adoption of fully automatic high-speed candy and biscuit packaging machines, technological advancements in the packaging process are profoundly transforming the industry’s production logic. This has become a core competitiveness for enterprises to reduce costs, improve efficiency, and seize market opportunities.

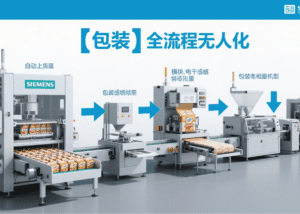

Efficiency Breakthrough: Full-Process Automation, Breaking Production Capacity Ceilings

The core advantage of fully automatic high-speed candy and biscuit packaging machines lies first in their efficient “full-process unmanned” operation. These devices integrate multiple functions such as automatic feeding, precise metering, forming and packaging, and sealing and cutting. From sorting and arranging candies to breakage-proof conveying of biscuits, and from automatic film feeding to precise bottom and side sealing, the entire process requires no manual intervention.

Take the production line of a well-known biscuit enterprise as an example: after introducing high-speed packaging machines, a single unit can complete 300-500 packages per minute, which is 3-5 times more efficient than traditional semi-automatic equipment. Moreover, it can operate stably 24/7, completely breaking the time constraints and fatigue bottlenecks of manual operations.

Quality Assurance: Enhanced Precision and Protection to Safeguard Product Value

Dual guarantees of precision and product protection are another key highlight. Candies and biscuits come in diverse shapes—candies can be round, square, or irregular, while biscuits require both crispness and integrity—placing high demands on the adaptability of packaging machines.

Fully automatic equipment, through the synergy of photoelectric sensors and servo control systems, automatically adjusts packaging film tension and cutting positions according to product sizes. This ensures that the metering error of each package is within ±1g, and the packaging sealing rate exceeds 99%, effectively isolating air and moisture to extend shelf life. For fragile biscuits, some high-end models are equipped with flexible conveying tracks and buffer pressing devices, reducing product breakage rates from 5% (with traditional packaging) to below 0.5% and significantly minimizing production losses.

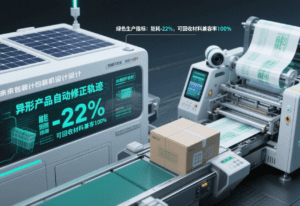

Flexible Adaptation: Empowered by Intelligence to Meet Diverse Market Demands

The deep integration of flexibility and intelligence enables the equipment to easily adapt to diverse market needs. With consumption upgrading, packaging forms for candies and biscuits have become increasingly varied—from single-piece individual packaging to multi-specification combination packs, and from transparent window bags to printed color film bags.

Fully automatic high-speed packaging machines allow quick parameter adjustments via touchscreens, enabling flexible changes to packaging specifications, patterns, and sealing methods. Changeover time is reduced from 1-2 hours (with traditional equipment) to less than 10 minutes. More advanced models are also connected to factory IoT systems, enabling real-time upload of production data (such as packaging quantity, equipment status, and material consumption). This facilitates remote monitoring and intelligent scheduling by managers, providing data support for flexible production and digital management.

Cost Optimization: Highlighting Long-Term Value to Drive Lean Production Transformation

In terms of cost control, the long-term value of fully automatic high-speed packaging machines is particularly prominent. Although the initial investment is high, over their full lifecycle, they significantly reduce labor costs (one machine can replace 6-8 workers), minimize packaging material waste (increasing film utilization by 15%-20%), and lower rework rates through stable production quality.

Practice at a candy enterprise shows that after introducing the equipment, the comprehensive cost of the packaging process decreased by approximately 30%, with an investment payback period of only 1-2 years.

Future Trends: Higher Adaptability and Greenization to Set New Industry Benchmarks

From an industry development perspective, fully automatic high-speed candy and biscuit packaging machines are moving toward “higher speed, better precision, and stronger adaptability.” In the future, with the application of AI visual recognition technology, equipment will more accurately identify irregular products and automatically correct packaging trajectories. Upgraded compatibility with environmentally friendly materials will also help the industry achieve the dual goals of “efficient production” and “green sustainability.”

For candy and biscuit enterprises, introducing such equipment is not just an upgrade of production tools, but a key step in transforming from “scale expansion” to “lean operation,” ultimately winning consumer favor through efficiency and quality in fierce market competition.