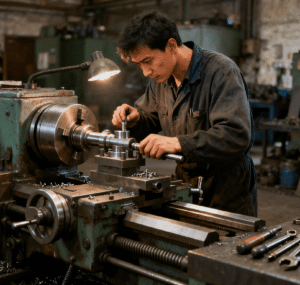

For a long time, the production of precision parts in the manufacturing industry relied on the manual operation of skilled workers. This model not only had limited efficiency but also saw its precision easily affected by human factors. A turning point came with the introduction of numerical control (NC) technology. By digitizing machining instructions and inputting them into a computer control system, machine tools can automatically execute complex cutting paths. This innovation has completely transformed the production method, freeing the machining process from absolute dependence on individual skills and significantly improving repeat precision and consistency. With the rapid development of computer processing capabilities, CNC systems have been continuously upgraded, making programming more convenient and efficient, and machining capabilities have been steadily enhanced. It is this evolutionary process from manual operation to high automation that has established the irreplaceable core position of CNC technology in today’s batch precision parts manufacturing field, paving the way for meeting the strict requirements of modern industry for precision, efficiency, and reliability.

Advantages of High-Precision Machining

The core advantage of CNC machining lies in its excellent high-precision machining capability, which directly promotes the wide application of customized batch precision parts manufacturing. Through the computer numerical control system, the machining process can achieve micron-level error control, ensuring that each part has consistent dimensions and meets strict standards, thereby greatly reducing the scrap rate and improving production efficiency. This precision advantage is particularly suitable for the medical and aerospace fields. For example, when manufacturing implantable devices or aircraft engine components, the surface finish and tolerance of parts are required to reach extremely high standards. In addition, the combination of high-precision machining and multi-axis technology further optimizes the ability to process complex geometric shapes, laying a solid foundation for subsequent multi-axis machining processes.

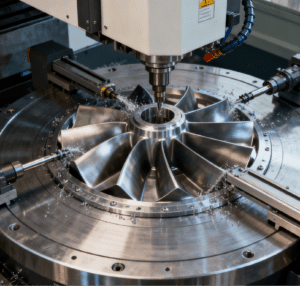

Multi-Axis Machining Technology

Compared with the traditional 3-axis machining method, multi-axis machining technology represents a major leap in the field of CNC machining. Its core lies in the fact that the machine tool is equipped with four or more controllable motion axes (usually including rotary axes), which can realize complex linkage of workpieces or cutting tools in multiple directions. This capability allows the cutting tool to cut into the workpiece from multiple angles or even continuously, eliminating the need for frequent manual re-clamping and positioning as required by 3-axis machine tools. For instance, a 5-axis machining center enables the worktable to rotate in multiple directions; when combined with the linear motion of the cutting tool, it can complete the machining of multiple surfaces or even the entire surface of parts with complex geometric shapes (such as turbine blades, precision medical implants, or aerospace structural components) in a single clamping. This technology greatly improves the machining efficiency and precision of complex curved surfaces, significantly reduces human errors, and serves as a key support for meeting the requirements of high complexity and strict tolerances in modern customized batch precision parts manufacturing. Moreover, the high-precision positioning and automation capabilities of CNC systems can also be integrated with auxiliary processes like automatic sealing ring feeding and assembly—for precision hydraulic components or medical instrument casings that require sealing, CNC-equipped automated lines can seamlessly connect machining with automatic feeding, positioning, and assembly of sealing rings, ensuring consistent assembly precision and avoiding leakage risks caused by manual operation errors.

Application Cases in the Medical and Aerospace Fields

It is precisely the high precision and multi-axis coordination capability of CNC machining that make it the first choice for customized batch precision parts manufacturing in the medical and aerospace fields. In the medical industry, CNC equipment can stably machine artificial joint implants with complex curved surfaces (such as knee joints and hip joints) and core components of minimally invasive surgical instruments with micron-level precision. These instruments have extremely high requirements for biocompatibility and surface finish and must pass strict certifications. In the aerospace field, multi-axis CNC technology can efficiently and reliably manufacture engine turbine blades, precision fuel nozzles, and aircraft frame connectors with complex structures. These parts not only have complex and variable shapes but also are often made of difficult-to-machine materials (such as titanium alloys and superalloys), and have nearly harsh requirements for machining dimensional consistency, surface integrity, and stress control. Relying on its programmability and repeat precision, CNC machining ensures the stable performance and reliable delivery of these key parts in batch production.

It can be seen that the maturity and popularization of CNC machining technology have completely reshaped the pattern of precision parts manufacturing. Its core advantage lies in the perfect combination of high-precision machining and multi-axis machining capabilities, which ensures that parts with complex geometric shapes can still maintain strict consistency in customized batch precision parts manufacturing. The high efficiency and stability brought by this technological accumulation are exactly the key factors that make it the preferred manufacturing method in the demanding medical and aerospace application fields. From initially replacing manual operations to now becoming the backbone of complex customized production, CNC machining has not only achieved a leap in production methods but also, through continuous technological iteration, provided the manufacturing industry with a reliable solution to meet diverse and high-precision needs, supporting the core demands of modern industry for precision, reliability, and rapid response.