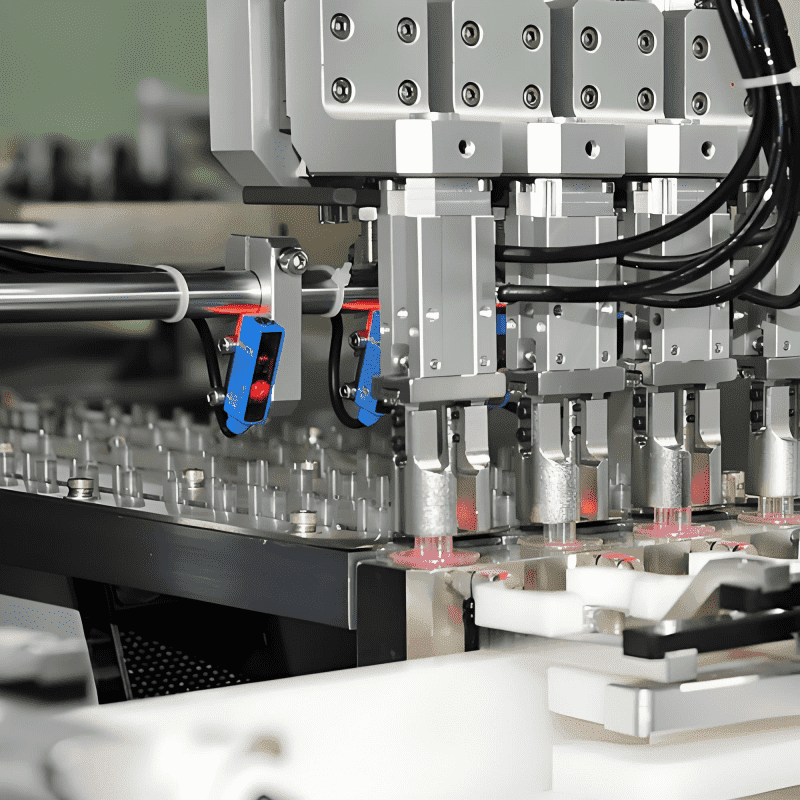

In 2011, when the concept of “Industry 4.0” was first introduced at the Hannover Messe in Germany, the global industrial sector could hardly have anticipated that 14 years later, the wave of artificial intelligence (AI) would permeate the production lines of modern factories at such a rapid pace: real-time transmission of PLC equipment data via 5G signals, cloud platforms automatically scheduling edge computing power to complete AI quality inspections, and sensors from different brands achieving seamless collaboration through standardized interfaces. This vision was brought to life at the 2025 Shanghai Industry Fair, where Schneider Electric showcased its intelligent flip machines and Ru Dong IoT Cube Robots.

This demonstration also served as a live showcase of Schneider Electric’s concurrently released Open Automation Empowering Factory Intelligent Solutions. As a global leader in industrial technology, Schneider Electric has long been deeply engaged in the field of open automation and launched an open automation platform five years ago. Today, it clearly presents to the industry the transformative changes that the global industrial sector is undergoing.

Currently, the global manufacturing industry is trapped in a “transformation paradox.” The traditional “black-box” control systems, represented by PLC + fieldbus, feature integrated hardware and software, closed protocols, and limited scalability. When faced with large-scale data empowerment, the deployment of AI models at the edge, and the integration of industrial cellular networks, these systems gradually reveal three critical flaws: “data silos,” “network barriers,” and “computing power bottlenecks.” These issues act like invisible shackles, rendering concepts such as flexible production, cross-domain collaboration, and global supply chain scheduling difficult to implement.

The introduction of open automation technology, however, achieves deep integration of IT (Information Technology) and OT (Operational Technology) by adopting software-defined approaches and open standards at the control layer. According to Open Automation Empowering Factory Intelligent Solutions, relying on standards such as IEC 61499 and OPC UA, Schneider Electric’s EcoStruxure Open Automation Platform (hereinafter referred to as the EAE Platform) decouples control logic from hardware, enabling free migration between industrial PCs and edge gateways. Meanwhile, the integration of 5G and TSN (Time-Sensitive Networking) builds a deterministic network to address cross-domain communication latency issues. Additionally, leveraging “cloud-edge-device” computing power collaboration, AI inference achieves millisecond-level response at the workshop level.

This paradigm shift not only provides technical support for realizing true “flexible manufacturing” but, more importantly, serves as an accelerator for the digital and intelligent transformation of industry. It shifts the focus of value creation from capital expenditure (CapEx) on fixed assets to operational expenditure (OpEx) on software services and innovation. Therefore, open automation is no longer just a technical option but a necessary prerequisite for the manufacturing system to address future challenges and secure a strategic competitive advantage.

Driven by the Wave of Intelligence: Open Automation Becomes a Consensus for Transformation

To understand why open automation has emerged globally, we must consider the in-depth needs of industrial evolution. Currently, the digital transformation of the global manufacturing industry has shifted from node-level “equipment intelligence” to comprehensive “smart factories.” However, the three structural bottlenecks of traditional industrial control systems—related to data, networks, and computing power—have become the biggest constraints on this process.

The solution logic of open automation is a systematic approach designed to address these pain points. As outlined in Open Automation Empowering Factory Intelligent Solutions, unlike the closed model of traditional systems where “software is tied to hardware,” software-defined automation separates control logic from proprietary hardware, forming a logical layer that can be migrated and scheduled across multiple hardware platforms (industrial PCs, edge gateways, real-time virtualized environments). At the same time, standardized interfaces (based on IEC 61499, OPC UA, TSN, etc.) enable protocol interoperability between IT and OT. Furthermore, edge-cloud collaboration schedules AI inference and data services to the most appropriate locations on demand, ensuring deterministic control while extending intelligent capabilities to production lines and equipment on a large scale.

From a macro global perspective, the rise of open automation aligns with the interests of multiple stakeholders. On one hand, many manufacturing powers around the world are leveraging smart manufacturing as a key means to enhance the resilience of their industrial chains. In this process, open standards and composable platforms help avoid lock-in to a single supplier, fostering an innovative ecosystem driven by multi-entity competition.

On the other hand, system integrators and software vendors see business opportunities in providing customers with integrated “equipment-platform-service” value through platform-based services. The open architecture facilitates the integration of innovations scattered among system integrators, independent software vendors (ISVs), and cloud service providers into deliverable industrial solutions. Take Schneider Electric as an example: in recent years, it has expanded its cooperative network through ecosystem partnership programs and built joint development and delivery capabilities across multiple industry scenarios—evidence that open automation has moved beyond the conceptual stage to ecological practice.

Against this backdrop, open automation has become a viable path to address the common pain points of the global manufacturing industry and an architectural choice for long-term evolvability. Through standardization, modularization, and ecological development, it not only lowers the threshold for enterprises’ digital transformation but also provides a long-term maintainable technical foundation for the large-scale deployment of intelligent capabilities.

Integration of “Network, Computing, and Control” Technologies and Ecological Collaboration: Exploring Innovative Practices in Smart Factories

While demand-driven factors have sparked the rise of open automation, scaling it from pilot projects to large-scale implementation requires deep integration of three types of technologies: industrial cellular networks (including 5G/private networks and TSN) to ensure determinism and bandwidth; edge-cloud collaboration and lightweight AI inference platforms to enable computing power and model deployment at the edge; and software-defined control and standardized interfaces to ensure system interoperability and rapid deployment.

Schneider Electric’s newly released Open Automation Empowering Factory Intelligent Solutions outlines a clear roadmap for the implementation of open automation—breaking traditional boundaries through multi-dimensional technology integration and unlocking industrial value through ecological collaboration. Schneider Electric’s EAE Platform has achieved engineering integration across this technology stack and jointly released a series of reports with operators, edge computing power providers, and software partners, mapping out a closed-loop roadmap from “network to computing power to control logic.”

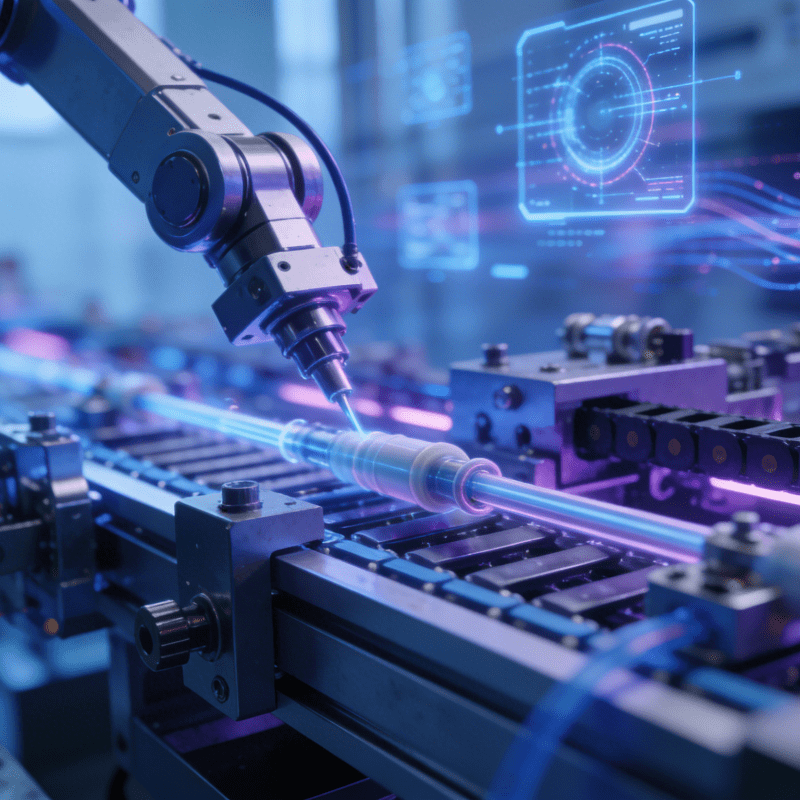

At the network level, the introduction of industrial cellular networks makes it feasible to expand workshop communication from wired buses to wireless industrial cellular networks. However, the key to enabling wireless networks to enter the control loop lies in ensuring “time sensitivity” and “determinism.” One solution is to combine 5G with TSN: TSN provides deterministic time scheduling at the local area network (LAN) layer, while 5G handles wide-area wireless coverage. This integration is not just a theoretical advancement but a practical enabler for even niche manufacturing equipment—such as a bathroom shower head assembling machine in a Chinese sanitary ware plant. This machine, once limited to single-model production by closed PLC systems, now connects torque sensors (for nozzle tightening), pressure sensors (for water flow testing), and vision cameras (for gasket alignment checks) via 5G+TSN. The wireless network ensures that assembly parameters (e.g., 0.8 N·m tightening torque for plastic nozzles) are transmitted to the edge gateway in real time, with latency kept below 10 milliseconds—critical for avoiding over-tightening or loose parts.

Furthermore, regarding software-defined control and protocol interoperability, traditional PLCs typically tie control logic, engineering tools, and hardware together, limiting the rapid iteration of control strategies. For the bathroom shower head assembling machine, this meant spending 4 hours reconfiguring hardware every time switching from a 3-function to a 5-function shower head. Now, with the EAE Platform’s software-defined architecture, operators simply call pre-built software modules (e.g., “multi-nozzle calibration” or “detachable handle assembly”) to complete the switch in 20 minutes—no hardware replacement required. Meanwhile, sensors from three different vendors (a German torque sensor, a Chinese pressure sensor, and a Japanese vision camera) communicate seamlessly via OPC UA, eliminating the “data silos” that once forced workers to manually log data from each device.

Secondly, the open automation architecture emphasizes “cloud-edge-device” three-tier computing power collaboration. Non-real-time data analysis and model training are conducted in the cloud; real-time inference and rapid closed-loop optimization are executed at edge nodes or edge containers; and direct I/O operations and high-speed control are still performed in local controllers or dedicated real-time environments. For the shower head assembling machine, this means the edge AI model can instantly analyze vision data to detect misaligned gaskets (a common defect) and adjust the mechanical arm’s position in 2 milliseconds—reducing defect rates by 35% compared to manual inspection. The cloud, meanwhile, aggregates data from 20 such machines across the plant to identify trends (e.g., higher defects during morning shifts due to temperature changes) and push optimized parameters back to the edge monthly.

The EAE Platform is built on this concept, aiming to establish a multi-vendor interoperable control software ecosystem where third-party algorithms, device drivers, and vertical industry applications can be quickly integrated on a unified platform. This foundation provided by open automation creates broader opportunities for breakthroughs in hardware technology—even for specialized equipment like bathroom shower head assemblers, which once struggled to keep up with the pace of intelligent transformation.

From Innovation to System Reconstruction: Unlocking New Value in the Global Industry

Globally, from Germany’s Industry 4.0 and the U.S. Advanced Manufacturing Partnership to China’s “Intelligent Transformation and Digital Upgrade” and ASEAN’s manufacturing upgrading strategies, open automation has become a common choice for major industrialized countries. This wave of innovation led by open automation is triggering systemic changes in the global manufacturing industry, and its value has long transcended individual technological upgrades to drive in-depth reconstruction of the industrial system.

In the past, intelligent transformation was often exclusive to large leading enterprises—due to high engineering costs and reliance on single solutions. Through standard interfaces, modular control, and ecological market mechanisms, open automation transforms “reusable control modules + industry-specific applications” into assets that can be purchased and integrated like apps from a software store. This allows small and medium-sized enterprises (SMEs) to obtain customized intelligent capabilities at lower costs. This is particularly important for countries with large manufacturing bases and fragmented ecosystems: when the transformation threshold is lowered, the marginal benefits of intelligence can accumulate across a wider range of enterprises, driving improvements in overall industrial chain efficiency and reallocation of the value chain.

Under the open architecture, new platform-based value distribution models have emerged among equipment manufacturers, system integrators, software vendors, and cloud service providers: equipment is no longer just a one-time-sold product but a source of data and services. Platform providers integrate these data and services through ecological governance to deliver comprehensive capabilities to end users. For system integrators, their capability boundaries extend from pure engineering delivery to continuous operation and optimization services; for software and AI vendors, open platforms provide channels for productization and large-scale adoption.

The release of Schneider Electric’s Open Automation Empowering Factory Intelligent Solutions has once again drawn industry attention to the value of this transformation—reconstructing the core competitiveness of manufacturing: when control logic is no longer constrained by hardware, the speed of innovation increases exponentially; when data is no longer fragmented by protocols, collaboration efficiency undergoes qualitative changes; when ecosystems are no longer blocked by barriers, industrial vitality is fully unleashed.

This technological revolution represented by open automation is accelerating the global manufacturing industry’s transition from a closed, isolated, experience-driven model to a new era of openness, collaboration, and algorithm-driven operations—injecting a steady stream of new momentum into the high-quality development of the global industrial system.

As Ding Xiaohong, Member of the Executive Committee of Schneider Electric Group, Senior Vice President, and Head of Industrial Automation Business in China, stated: “Genuine industrial intelligence must be built on the integration of hardware and software, as well as the integration of IT and OT. Only then can intelligent connectivity be achieved from the perception layer to the decision-making layer, and from the device end to the cloud.” The wave of open automation showcased at the 2025 Industry Fair has already begun to unfold on a global scale.

Automatic assembly machine for switch components

AI automatic assembly robot for switch components