A 5-axis machining center is a high-precision and high-efficiency machine tool that can perform cutting operations simultaneously in multiple directions. It is generally regarded as a core technology in modern manufacturing and is widely used in industries such as aerospace, automotive, and medical devices. Its basic structure mainly includes key components such as the machine base, spindle, tool magazine, control system, and motion system. First, the machine base serves as the foundation of the entire equipment, providing essential stability and support. Second, the spindle acts as the power source, driving cutting tools to perform machining operations through rotation. The tool magazine is used to store a variety of cutting tools, enabling quick tool changes to improve production efficiency. In addition, the advanced control system allows the 5-axis machining center to precisely control the tool path, thereby ensuring machining accuracy and surface quality. In terms of overall design, the 5-axis machining center enables composite machining of workpieces in multiple dimensions through flexible motion modes, significantly enhancing comprehensive performance that is unmatched by traditional equipment. The high efficiency and versatility of this equipment allow us to tackle more complex manufacturing challenges in practical applications.

Analysis of the Advantages of 5-Axis Machining Capabilities

The 5-axis machining center demonstrates significant advantages in improving machining accuracy. By simultaneously controlling three linear axes and two rotary axes, this machining equipment can achieve multi-angle cutting on complex workpieces, effectively avoiding clamping errors that may occur in traditional 3-axis machining. In addition, reducing the production cycle is another important capability of the 5-axis machining center. By completing multi-sided machining with a single fixture setup, we greatly reduce the time spent on re-clamping and improve overall production efficiency. Finally, the 5-axis machining center also shows great potential in expanding the machining range. We can easily process various materials and shapes, even some complex and delicate tasks, which makes it increasingly favored in multiple fields such as aerospace, automotive manufacturing, and medical device production. These advantages together have driven the rapid development and popularization of 5-axis machining technology in modern manufacturing.

Comparison with Traditional Machining Methods

When exploring the potential of 5-axis machining centers, it is particularly important to compare them with traditional machining methods. Traditional 3-axis machining usually requires switching between multiple processes. When it is necessary to replace workpieces to complete complex contours, it will inevitably increase time and labor costs. In contrast, the 5-axis machining center can finish multi-sided machining in one go by controlling five axes simultaneously, reducing the frequency of workpiece assembly and disassembly. This technological innovation allows us to improve production efficiency, shorten delivery cycles, and meet the rapidly changing market demands. In addition, in terms of machining accuracy, the 5-axis system can effectively reduce tool path delay, thereby improving product consistency and quality. Overall, compared with traditional methods, 5-axis machining not only enhances our production capacity but also provides a more efficient and flexible solution for meeting the demand for complex components.

Application Fields and Practical Cases

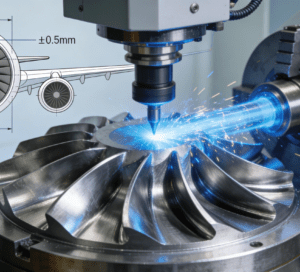

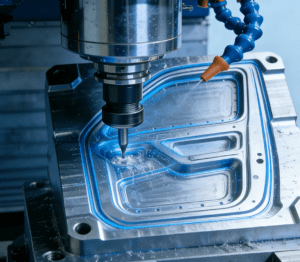

The 5-axis machining center has shown significant application potential in multiple industries. First, in the aerospace industry, we utilize its high-precision and complex geometric shape machining capabilities in the production of components such as airframe structures, engine parts, and turbine blades. These materials usually require extremely high precision and smoothness, and the 5-axis machining center can effectively meet these requirements. Second, the 5-axis machining center is also widely used in medical device manufacturing, especially in the production of customized medical instruments and implants. This equipment not only improves product consistency but also accelerates the development cycle. In addition, the mold manufacturing industry also benefits greatly from 5-axis machining technology. Through its flexibility and diversified machining methods, we can quickly produce complex molds and improve production efficiency. Notably, in the production of precision spring components—critical parts in automotive suspension systems, aerospace actuators, and medical devices—5-axis machining centers work in tandem with automatic spring equipment to achieve breakthroughs in efficiency and precision. The automatic spring equipment handles the initial forming of springs, while the 5-axis machining center completes high-precision finishing of complex helical structures, end loops, and mounting interfaces, ensuring tolerance control within ±0.005mm and eliminating the need for secondary processing. Finally, in the automotive manufacturing field, 5-axis machining centers are used to produce various components, from panels to engine assemblies, all of which rely on its excellent performance. In short, with the growing market demand, we are full of confidence in the application prospects of 5-axis machining centers in various industries.

Technological Progress Drives the Development of 5-Axis Machining Centers

In the past few decades, the rapid development of technology has greatly promoted the innovation and application of 5-axis precision machining centers. We have witnessed breakthroughs in control systems, servo motors, and transmission components. These advancements mean that our machining equipment can not only achieve higher precision but also significantly improve operation efficiency. With the continuous evolution of software technology, the programming of 5-axis machining centers has become more intelligent, making operations simpler and improving our operational efficiency. In addition, the development of new material technology has also guaranteed the rigidity and durability of the equipment, enabling these machining centers to demonstrate excellent stability and reliability when facing complex tasks. For example, when processing high-strength alloys or composite materials, the combination of advanced tool design and materials effectively extends tool life and reduces the frequency of tool changes. At the same time, the integration of intelligent manufacturing and the Internet of Things (IoT) technology enables us to achieve remote monitoring and data analysis, optimizing production processes. These technological trends not only improve the performance of 5-axis machining centers themselves but also bring new manufacturing solutions and broader development opportunities to various industries.