In the era of “small-batch, multi-variety” manufacturing, where production lines need to switch between different products in minutes rather than hours, traditional rigid equipment often becomes a bottleneck. Among them, the vibratory feeder—an essential device for transporting small to medium-sized parts (such as screws, chips, and medical components) in automated workflows—has long struggled with “inflexibility”: fixed feed paths, long changeover times, and high risk of damaging fragile materials. Today, the Flexible Vibratory Feeder has emerged as a game-changer, breaking through these limitations and becoming a core component in industries ranging from electronics to medical devices, empowering production lines to adapt to rapidly changing market demands.

What Is a Flexible Vibratory Feeder? Breaking Down Its Core Value

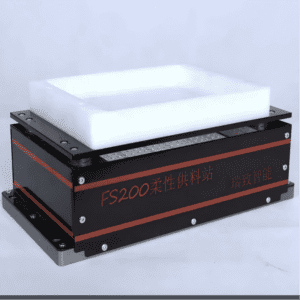

A Flexible Vibratory Feeder is an advanced material handling device that uses controlled vibration to sort, orient, and transport parts—while integrating “flexibility” into every aspect of its design. Unlike traditional vibratory feeders (which use rigid metal trays and fixed vibration parameters), it leverages modular structures, adaptive control systems, and soft-contact materials to achieve three key goals:

Rapid product changeover: Switch between different part types (e.g., from 3mm electronic connectors to 8mm automotive screws) in 5–10 minutes, compared to 1–2 hours for traditional models.

Gentle material handling: Protect fragile or high-precision parts (such as semiconductor chips, glass syringes, and ceramic capacitors) from scratches or deformation.

Intelligent adaptability: Adjust vibration frequency, amplitude, and direction in real time based on part characteristics and production line needs, ensuring stable feeding even for irregularly shaped components.

In short, it transforms the vibratory feeder from a “one-task machine” into a “multi-role collaborator” that fits seamlessly into flexible manufacturing systems.

Core Technologies: How Flexibility Is Achieved

The “flexibility” of this equipment is not just a marketing term—it is supported by four key technological innovations:

- Modular, Quick-Change Feed Trays

The most visible innovation is the use of lightweight, customizable feed trays made from food-grade silicone, polyurethane, or engineering plastics (instead of rigid steel). These trays are designed with:

Interchangeable magnetic bases: No tools are needed to attach or remove trays—operators simply snap the new tray into place, aligning with the feeder’s vibration source.

Customizable contours: Trays can be 3D-printed or injection-molded to match the shape of specific parts (e.g., U-shaped grooves for cylindrical pins, recessed slots for square chips). For small-batch production, some manufacturers even offer “universal trays” with adjustable dividers to fit multiple part sizes.

This modular design eliminates the need for time-consuming mechanical adjustments (such as re-calibrating feed paths) when switching products.

- Adaptive Vibration Control Systems

Traditional vibratory feeders use fixed vibration parameters (e.g., 50Hz frequency, 2mm amplitude), which often cause problems: too much vibration damages fragile parts, while too little leaves parts stuck. Flexible models solve this with closed-loop adaptive control:

A built-in sensor (laser or vision-based) monitors the flow of parts in real time—if parts pile up, the system reduces amplitude; if parts move too slowly, it increases frequency slightly.

Pre-set parameter libraries: Operators can store 50+ sets of vibration data (e.g., “silicone O-rings: 40Hz, 1.2mm amplitude”; “aluminum screws: 60Hz, 1.8mm amplitude”) and call them up with one click when changing products.

This ensures consistent feeding efficiency across different part types, with a stability rate of over 98%.

- Soft Vibration Sources & Noise Reduction

To protect fragile materials, flexible vibratory feeders use electromagnetic vibration drives instead of the eccentric wheel drives in traditional models. Electromagnetic drives generate smoother, more controllable vibration (with no mechanical friction) and can adjust force in micro-increments—critical for parts like thin-walled plastic connectors or glass optical components.

Additionally, the feeder’s base is equipped with rubber shock absorbers, reducing operating noise to 55–65 decibels (comparable to a normal conversation), far lower than the 80–90 decibels of traditional feeders. This improves workshop working conditions and meets occupational health standards.

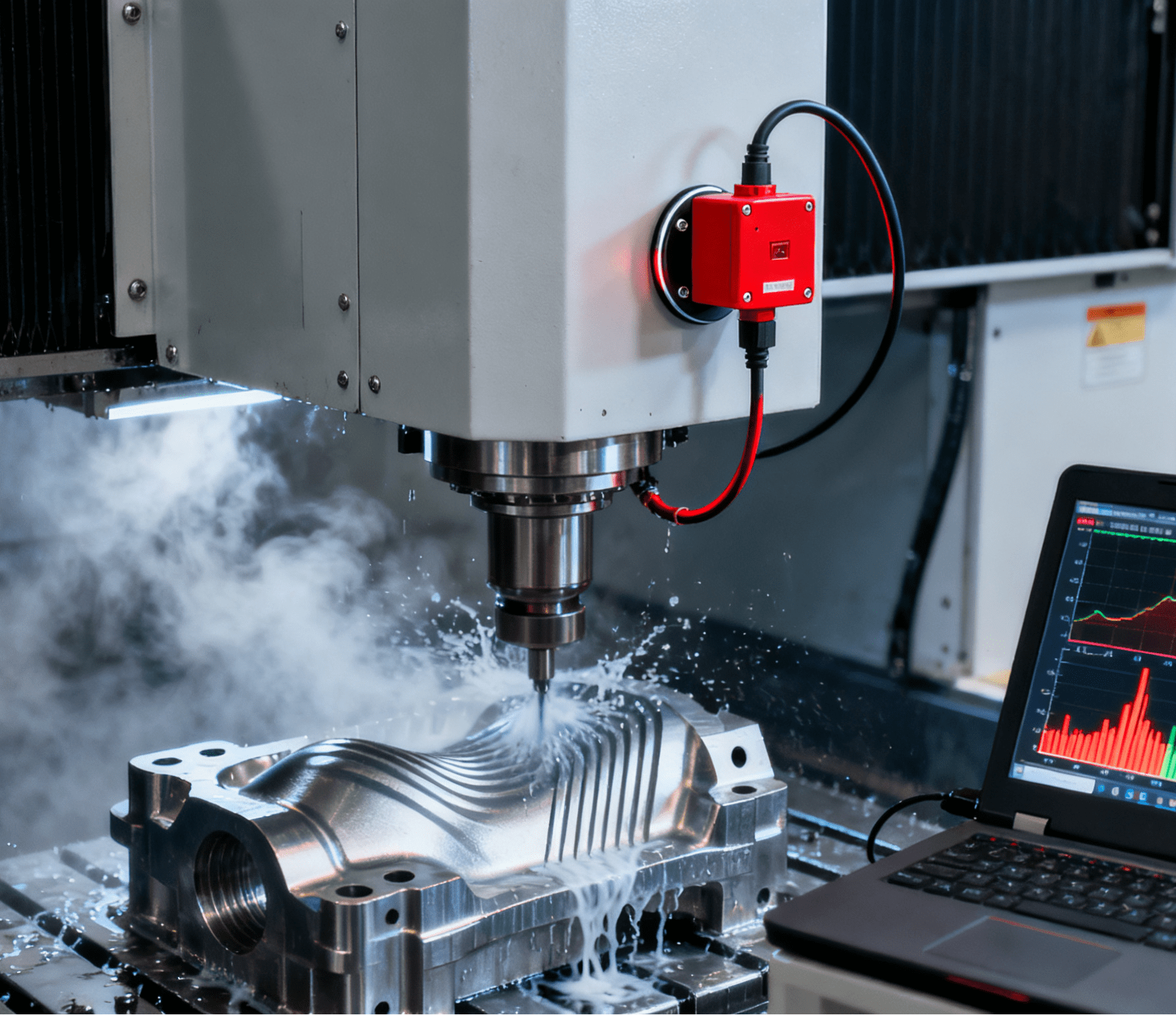

- Integration with Intelligent Production Systems

Modern flexible vibratory feeders are not standalone devices—they support connectivity with MES (Manufacturing Execution Systems) and IoT platforms. Through Ethernet or Wi-Fi, they can:

Transmit real-time data: Feed rate (parts per minute), tray status, and vibration parameters to the central control system.

Receive remote commands: For example, if the downstream assembly robot is temporarily idle, the feeder automatically reduces speed to avoid part accumulation; when production resumes, it ramps up immediately.

Log maintenance data: The system alerts operators when the vibration drive needs calibration or the tray needs replacement, reducing unplanned downtime.

Real-World Applications: Transforming Industries

The flexibility of this equipment makes it indispensable in industries where product variety and precision are critical:

- Electronic Component Manufacturing

In PCB (printed circuit board) assembly lines, manufacturers often need to feed dozens of different components (resistors, capacitors, connectors) in one shift. A leading electronics contract manufacturer in Shenzhen replaced 8 traditional vibratory feeders with 4 flexible models, cutting product changeover time from 2 hours to 8 minutes. The feeder’s soft silicone trays also reduced damage to 0402-sized resistors (the smallest common electronic component) from 3% to 0.1%.

- Medical Device Production

For disposable syringes, insulin pens, and surgical instruments, cleanliness and part integrity are non-negotiable. Flexible vibratory feeders with stainless steel and food-grade silicone components (easy to clean and sterilize) are widely used here. A medical device company in Suzhou uses these feeders to transport glass syringe barrels—thanks to the adaptive vibration control, the barrels are fed upright without tipping, and the defect rate due to scratches dropped from 5% to 0.3%.

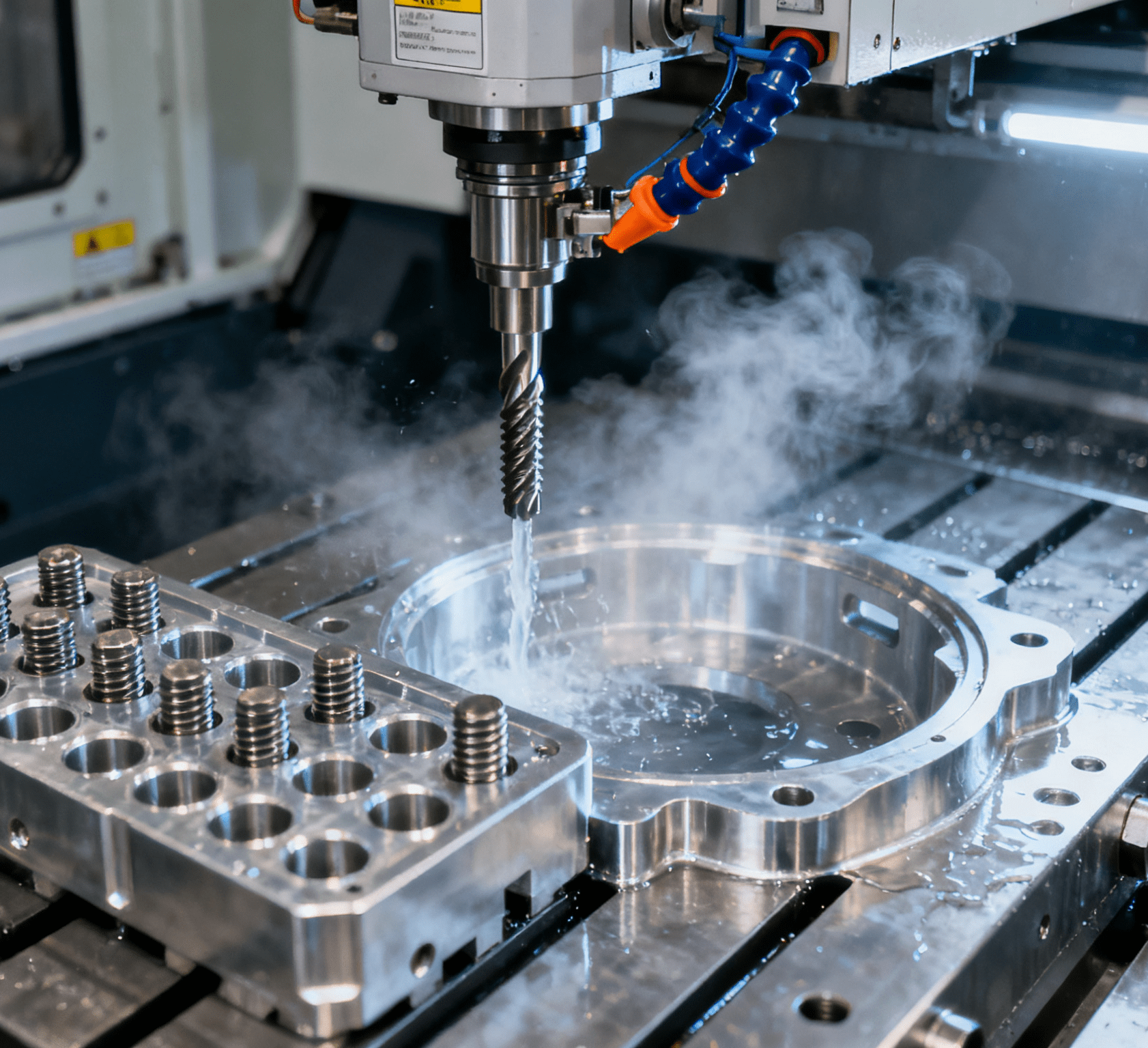

- Automotive Precision Parts Assembly

Automotive electronics (e.g., sensor connectors, battery terminals) require high-precision feeding. A global automotive parts supplier uses flexible vibratory feeders to feed micro-machined aluminum pins (with a diameter of 1.5mm) to robotic assembly arms. The feeder’s vision sensor ensures the pins are oriented correctly (with a 99.9% accuracy rate), eliminating manual rework and increasing assembly efficiency by 25%.

- Food & Pharmaceutical Packaging

In the pharmaceutical industry, flexible vibratory feeders with FDA-approved materials are used to transport capsules, tablets, or small plastic pill bottles. The gentle vibration prevents capsules from cracking, and the quick-change trays allow switching between different capsule sizes (e.g., 00# to 3#) in 5 minutes—ideal for small-batch production of specialty drugs.

Future Trends: More Flexible, More Intelligent

As manufacturing moves toward “mass customization,” flexible vibratory feeders will evolve further:

AI-powered adaptive control: Future models will use machine learning to analyze part characteristics (weight, shape, friction coefficient) and automatically generate optimal vibration parameters, eliminating the need for manual setup.

3D-printed quick-change trays: On-demand 3D printing of trays (using biodegradable materials) will reduce lead times for custom trays from days to hours, supporting ultra-small-batch production.

Miniaturization: Compact flexible feeders (with a footprint of less than 0.2 square meters) will be developed for use in collaborative robot workcells, enabling “one-robot-one-feeder” flexible production units.

Conclusion: A Small Device Driving Big Changes in Manufacturing

The Flexible Vibratory Feeder may seem like a “small part” of the production line, but its impact is far-reaching. By solving the long-standing pain points of traditional feeders—slow changeover, part damage, and poor adaptability—it enables manufacturers to respond faster to market demands, improve product quality, and reduce costs. In the era of intelligent, flexible manufacturing, the Flexible Vibratory Feeder is not just a tool—it is the “flexible backbone” that connects different parts of the production line, making mass customization and efficient small-batch production a reality. For any manufacturer aiming to stay competitive in the future, investing in this technology is no longer an option but a strategic necessity.