In the automated production of precision machinery, fixtures are indispensable tools that play a key role in achieving high-precision and high-efficiency machining. Their design and application are particularly crucial for enterprises focusing on high-end manufacturing such as Ares Precision Machinery, as well as in the medical equipment and parts industry (including dental equipment and supplies, medical devices, and other fields).

The Functions of Fixtures

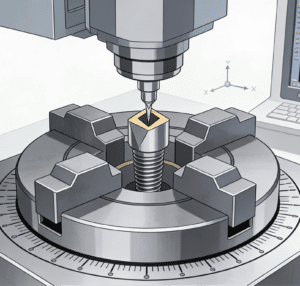

Improving Machining Accuracy

Through accurate positioning and stable clamping, fixtures can ensure the positional and dimensional accuracy of workpieces during machining. This is especially important in the processing of medical equipment and parts. For example, in the production of dental implants, the precision of fixtures directly affects the fit between the implant and the patient’s alveolar bone, which is related to the success rate of the surgery and the patient’s user experience. Only high-precision fixtures can ensure that parameters such as the thread size, shape, and position of implants meet strict medical standards.

Enhancing Production Efficiency

The use of fixtures enables rapid clamping and positioning of workpieces, reducing the time spent on manual adjustment and alignment, thus greatly improving production efficiency. This advantage is more pronounced in mass production. By optimizing fixture design, Ares Precision Machinery has realized the automation and high efficiency of production lines, and can quickly and accurately complete the processing of a large number of medical equipment parts. To further amplify the efficiency of automated production, Ares has also integrated the 4 – Axis Robotic Tray Loading System with its high-precision fixtures. This system utilizes the flexible positioning capability of 4-axis movement to automatically load and unload workpiece trays, and seamlessly links with fixtures and CNC machine tool control systems to realize continuous feeding of workpieces to fixtures and transfer of finished parts. It completely eliminates manual tray handling and workpiece transfer time, and ensures that fixtures can always maintain a high-frequency clamping state in batch processing of small medical parts, significantly increasing the overall throughput of the production line.

Meanwhile, fixtures can be used in conjunction with the automated control systems of machine tools to achieve multi-station or continuous machining, further boosting production efficiency. For instance, in CNC machining centers, the use of rotatable fixtures or automatic fixture changing devices allows multiple surfaces or processes to be completed in a single clamping, reducing the number of workpiece loading and unloading operations and auxiliary machining time.

Ensuring Machining Consistency

In mass production, fixtures can ensure that the clamping position and clamping force of each workpiece remain consistent during processing, thereby guaranteeing the stability and consistency of machining quality. This is critical for the medical equipment and parts industry, as these products often require strict quality control and traceability. For example, in the production of medical devices, using the same fixtures can ensure that the dimensional accuracy and surface quality of each part are within the specified range, avoiding product quality fluctuations caused by human factors or clamping differences. This not only improves the product qualification rate but also reduces the cost and workload of quality inspection.

Expanding the Scope of Machining Processes

Some specially designed fixtures can enable special machining processes, such as the processing of irregular parts and multi-surface machining. Through the innovative design of fixtures, Ares Precision Machinery can provide more diversified processing solutions for the medical equipment and parts industry to meet the needs of different customers. For example, for some dental equipment and supplies with complex shapes, the design of special fixtures allows complex machining processes to be carried out on ordinary machine tools, reducing production costs and equipment investment. At the same time, fixtures can be used with other auxiliary tools (such as cutting tools and measuring tools) to further expand the possibilities of machining processes.

Fixtures play an irreplaceable role in the automated production of precision machinery. Their design and manufacturing are directly related to machining accuracy, production efficiency, and product quality. Enterprises such as Ares Precision Machinery continue to innovate and optimize the design and application of fixtures, providing strong support for high-end manufacturing fields such as the medical equipment and parts industry. With the continuous advancement of science and technology and the development of the manufacturing industry, the design and technology of fixtures will also be continuously innovated and improved, making greater contributions to promoting the development of the precision manufacturing industry.