Modern Manufacturing’s Precision Demands and the Role of Five-Axis CNC

In modern manufacturing, the precision requirements for complex parts are becoming increasingly stringent. With the continuous development of industries such as aerospace, automotive, and medical devices, the demand for high-precision components with complex shapes and curved surfaces has surged. Traditional machining methods often struggle to meet these exacting standards, especially when dealing with intricate geometries.

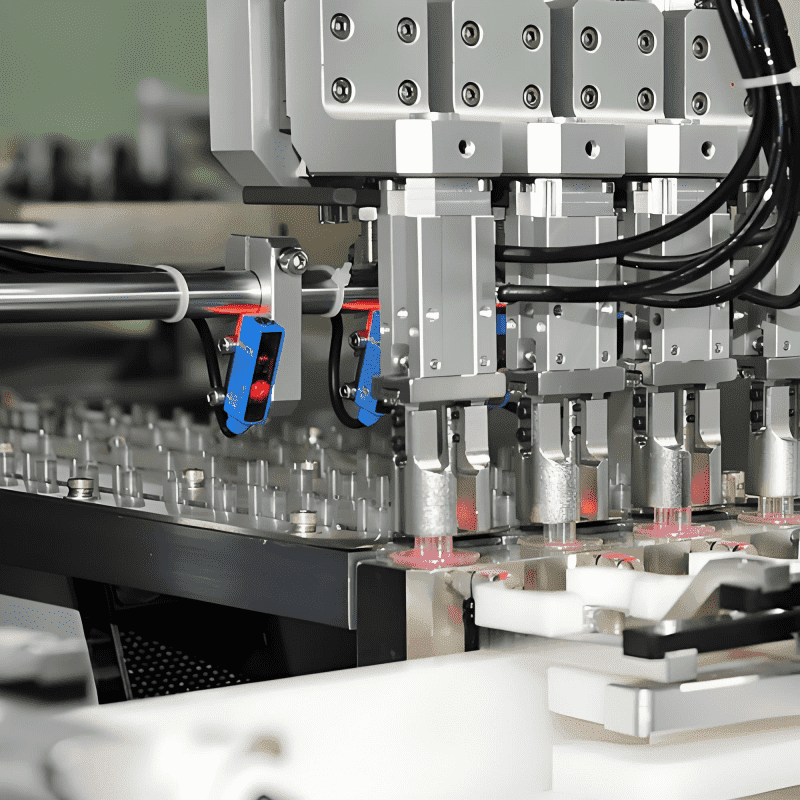

This is where the five-axis linkage CNC machining center comes into play. As a revolutionary tool in the manufacturing landscape, it has emerged as the key solution to the challenges of machining curved surfaces and irregularly shaped parts. Thanks to its multi-dimensional motion capabilities, this advanced equipment can manipulate the tool in multiple directions simultaneously, providing an unprecedented level of flexibility and accuracy. Notably, in the integrated manufacturing of products combining metal precision components and injection-molded parts, the five-axis CNC machining center synergizes seamlessly with the Injection Molded Parts Automated Assembly System with Auto-Loading—the micron-level precision of CNC-machined metal structures provides standardized positioning references for the assembly system, ensuring stable and accurate integration of injection-molded parts.

Core Technology Analysis of Five-Axis Linkage

The core of a five-axis linkage CNC machining center lies in the coordinated operation of its five motion axes. Among them, the three linear axes (X/Y/Z) are responsible for controlling the spatial movement of the tool, determining the position of the tool in the three-dimensional space of length, width, and height. For example, in the machining of a complex part, the X-axis can move the tool horizontally, the Y-axis can move it vertically, and the Z-axis can control its up-and-down movement.

The two rotary axes (A/C or B/C) play a crucial role in adjusting the angle direction of the workpiece or the tool. For instance, in the production of an aircraft engine blade, the A-axis, which rotates around the X-axis, and the C-axis, which rotates around the Z-axis, can precisely change the orientation of the workpiece or the tool. This allows for the machining of complex curved surfaces from various angles. The combination of these multiple degrees of freedom enables the tool to reach any point on the workpiece surface from an arbitrary angle, making it particularly suitable for processing complex curved surface structures such as aircraft blades and medical implants.

To achieve high-precision synchronous motion, the equipment is equipped with a closed-loop servo control system. This system functions by continuously and in real-time feeding back the position data of each axis. For example, an encoder installed on the axis can accurately measure the actual position of the axis during movement. The control system compares this actual position with the preset position in the machining program. If there is a deviation, the system immediately calculates the correction amount and sends control signals to the servo motor to dynamically correct the trajectory deviation. For example, when cutting an arc-shaped contour, the numerical control system will simultaneously calculate the angle of the rotary axis and the displacement of the linear axis. By precisely controlling the rotation angle of the A and C axes and the linear movement of the X, Y, and Z axes, it ensures that the cutting point is always perpendicular to the normal of the curved surface. This results in high-quality machining with consistent surface finish and dimensional accuracy. Additionally, the dynamic compensation system, through monitoring temperature fluctuations and mechanical vibrations, automatically fine-tunes the tool path, maintaining the positioning accuracy within ±3 microns.

Precision Breakthrough Solutions for Curved Surface Machining

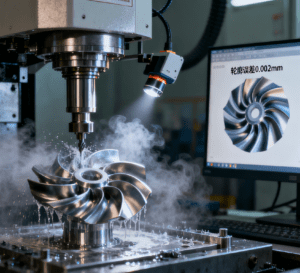

In response to the high-precision machining requirements of complex curved surfaces, the five-axis linkage CNC machining center achieves technological breakthroughs through multi-dimensional coordinated control. The equipment makes full use of the synchronous motion of the rotary axes and linear axes. This allows the tool to always contact the workpiece surface at the optimal angle. By doing so, it effectively reduces vibrations and deformations during the cutting process. For example, when machining a complex curved surface of a high-performance engine component, the synchronous movement of the axes ensures that the cutting force is evenly distributed, minimizing the risk of surface roughness and dimensional errors caused by uneven forces.

To address interference factors such as temperature fluctuations and material stress, the dynamic compensation system plays a crucial role. It continuously monitors the machining status in real-time. High-precision sensors are installed at various key positions on the machine tool, such as on the spindle, bed, and workpiece fixture. These sensors can detect parameters like temperature changes, mechanical vibrations, and tool wear. Once the system detects any deviation from the optimal machining conditions, it automatically corrects the tool path deviation. The precision control can reach within ±3 microns.

Take the aviation engine blade as an example. The curved surface contour error of the blade is compressed to 1/20 of the diameter of a human hair. This extremely high-precision machining meets the stringent requirements of aerodynamic performance. The shape and surface quality of the engine blade directly affect the efficiency and performance of the engine. With the five-axis linkage CNC machining center, the fine-tuning of the tool path by the dynamic compensation system ensures that the blade’s curved surface can achieve the required accuracy, reducing air resistance and improving engine thrust.

Through the intelligent tool path optimization algorithm, the system can also increase the machining efficiency by 30%. The algorithm analyzes the 3D model of the workpiece and the machining requirements in advance. It then plans the most efficient tool path, reducing unnecessary movements such as air-cutting and overlapping paths. This not only shortens the machining time but also improves the surface quality of the workpiece, avoiding issues such as surface scratches and unevenness caused by redundant tool paths. This efficiency advantage is further amplified in integrated production lines, where the CNC machining center’s high-speed precision machining is matched with the continuous operation of the Injection Molded Parts Automated Assembly System with Auto-Loading, significantly improving the overall production efficiency of complex assemblies.

Intelligent Tool Path Optimization and Dynamic Compensation

In modern five-axis machining systems, intelligent tool path optimization technology plays a crucial role in achieving precise planning and dynamic adjustment of the tool path. When dealing with complex curved surfaces or irregular structures, the control system will analyze the 3D data of the workpiece in real-time. Based on this analysis, it automatically generates a motion trajectory that can not only avoid interference areas but also reduce the idle-running time of the tool. This algorithm takes into account not only the contact angle between the tool and the workpiece but also adjusts the cutting parameters according to the material properties. For example, when machining titanium alloy, which has high strength and low thermal conductivity, the system will automatically reduce the feed rate to prevent overheating. Excessive heat during the machining of titanium alloy can lead to workpiece deformation, tool wear, and a decline in surface quality. By reducing the feed rate, the heat generated during cutting can be effectively controlled, ensuring the machining quality.

The dynamic compensation system is equally important in this process. It continuously monitors variables such as the vibration of the machine tool spindle and temperature-induced deformation through high-precision sensors. These sensors are distributed at key positions on the machine tool, such as on the spindle, bed, and tool holder. When the system detects that the tool has deviated by a micron-level due to long-term machining, it can recalculate the compensation value within 0.01 seconds. This ensures that the cutting point always coincides with the preset path.

This closed-loop control mechanism is particularly suitable for the multi-angle machining of medical device joint components. Even after continuous operation for 12 hours, it can still maintain a positioning accuracy of ±3 microns. The high-precision machining of medical device joint components requires strict control over the shape and surface quality of the parts. The dynamic compensation system can correct the tool path in real-time according to the changes in the machining process, ensuring that the parts meet the high-standard requirements for implantation in the human body. For medical devices that integrate CNC-machined metal joints and injection-molded plastic components, this precision also ensures that the parts can be seamlessly matched with the Injection Molded Parts Automated Assembly System with Auto-Loading, avoiding assembly errors caused by dimensional deviations.

Zero-Error Manufacturing Applications for Irregular Parts

When faced with the machining requirements of complex curved surfaces and irregular structures, the five-axis linkage CNC machining center demonstrates unique advantages.

In the aerospace field, components such as engine turbine blades are typical irregularly shaped parts. These parts need to balance both aerodynamics and structural strength. Traditional machining methods, due to multiple clamping operations, are prone to error accumulation. For example, in the past, when machining turbine blades, the need to re-position the workpiece multiple times during different machining steps could lead to cumulative errors in the overall shape and dimensions of the blade. This would affect the aerodynamic performance of the engine, reducing efficiency and increasing fuel consumption.

However, with the intelligent tool path optimization technology, the system can automatically plan the tool path. It takes into account the material properties of the blade, such as high-temperature alloys with low thermal conductivity and high strength. By avoiding vibrations caused by material characteristics or geometric mutations, it ensures the integrity of the machining process. The dynamic compensation system plays a vital role in real-time monitoring of the machining status. It can automatically adjust the spindle speed and feed rate. When the temperature rises during machining, which may cause thermal deformation of the workpiece, the dynamic compensation system can quickly respond. It adjusts the machining parameters to control the error caused by thermal deformation and mechanical vibration within ±3 microns. This high-precision machining ensures that the turbine blades meet the strict aerodynamic requirements, improving the performance and reliability of the engine.

The medical device field also benefits significantly from this technology, especially in the manufacturing of artificial joints. The complex biocompatible curved surfaces of artificial joints require extremely high-precision machining. With the five-axis linkage CNC machining center, these complex surfaces can be precisely machined in one clamping. The intelligent tool path optimization technology ensures that the tool moves along the most appropriate path, avoiding unnecessary collisions and ensuring the accuracy of the surface shape. The dynamic compensation system continuously monitors the machining process. Even if there are slight changes in the machining environment, such as temperature fluctuations or minor tool wear, it can quickly adjust to ensure that the surface roughness of the artificial joint can reach below Ra0.2μm. This meets the stringent standards for human implants, reducing the risk of rejection and improving the quality of life for patients.

In the automotive industry, the synergy between the two technologies is even more prominent. For example, in the production of automotive transmission system components that combine CNC-machined metal gears and injection-molded plastic housings, the five-axis CNC machining center ensures the gear’s tooth profile accuracy and shaft hole precision. The Injection Molded Parts Automated Assembly System with Auto-Loading then uses its auto-loading mechanism to feed the injection-molded housings and automatically assemble them with the precision gears. The consistent dimensional accuracy between the two types of parts, guaranteed by the CNC machining center, enables the assembly system to achieve a 99.5% pass rate, significantly reducing manual intervention and improving production stability.

Conclusion: The Value and Prospect of Five-Axis Linkage CNC Technology

The innovative application of five-axis linkage CNC machining technology has achieved remarkable results. It has provided a reliable path to solve the manufacturing challenges of complex curved surfaces and irregularly shaped parts. Through multi-angle coordinated cutting and real-time dynamic compensation, the equipment can automatically correct errors generated during the machining process due to material deformation or tool wear, ensuring that key dimensions are stably within the micron-level accuracy range.

The intelligent tool path optimization system further enhances machining efficiency. By using algorithms to predict the best combination of tool paths, it reduces the time losses caused by empty travel and repeated positioning. In the aerospace field, this technology has enabled the highly consistent production of turbine blade aerodynamic surfaces. The high-precision machining of turbine blades ensures the efficient operation of aircraft engines, improving flight safety and fuel efficiency. In medical device manufacturing, it has helped achieve nearly perfect surface finish for artificial joints and other irregular components. High-quality artificial joints can better match the physiological functions of the human body, reducing patient pain and improving the success rate of implantation surgery. In integrated manufacturing scenarios, its synergy with the Injection Molded Parts Automated Assembly System with Auto-Loading has opened up new possibilities for high-precision, high-efficiency production of complex assemblies.

These achievements not only verify the engineering value of five-axis linkage technology but also play a crucial role in promoting precision manufacturing towards the goal of zero-error. They have significantly improved the quality and efficiency of manufacturing in high-end industries, enhancing the competitiveness of products in the global market. Looking ahead, with the continuous development of technology and the increasing demand for high-precision components in various industries, five-axis linkage CNC technology will continue to innovate and develop. It is expected to be applied in more fields, bringing more advanced manufacturing solutions and contributing to the continuous progress of the global manufacturing industry.

How to choose a multi-component capping assembly machine suitable for your production line?