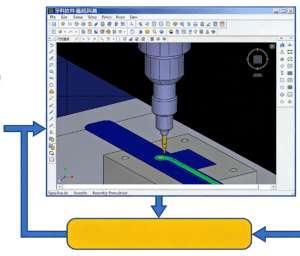

The core of precision digital manufacturing lies in the precise control of the machining process through programming. By virtue of sophisticated algorithms and advanced control principles, it achieves a seamless connection from design to finished products, laying a solid foundation for the production of high-precision items.

Technical Core of Programming-Driven Accurate Machining: Algorithms and Control

Programming plays a vital role in precision digital manufacturing. First and foremost, programmers need to convert design drawings into machine-understandable instructions using specific programming languages and software in accordance with product design requirements. These instructions cover the movement trajectory of machining tools, cutting parameters, feed rate and other aspects. Precise control over these parameters ensures the accuracy and stability of the machining process.

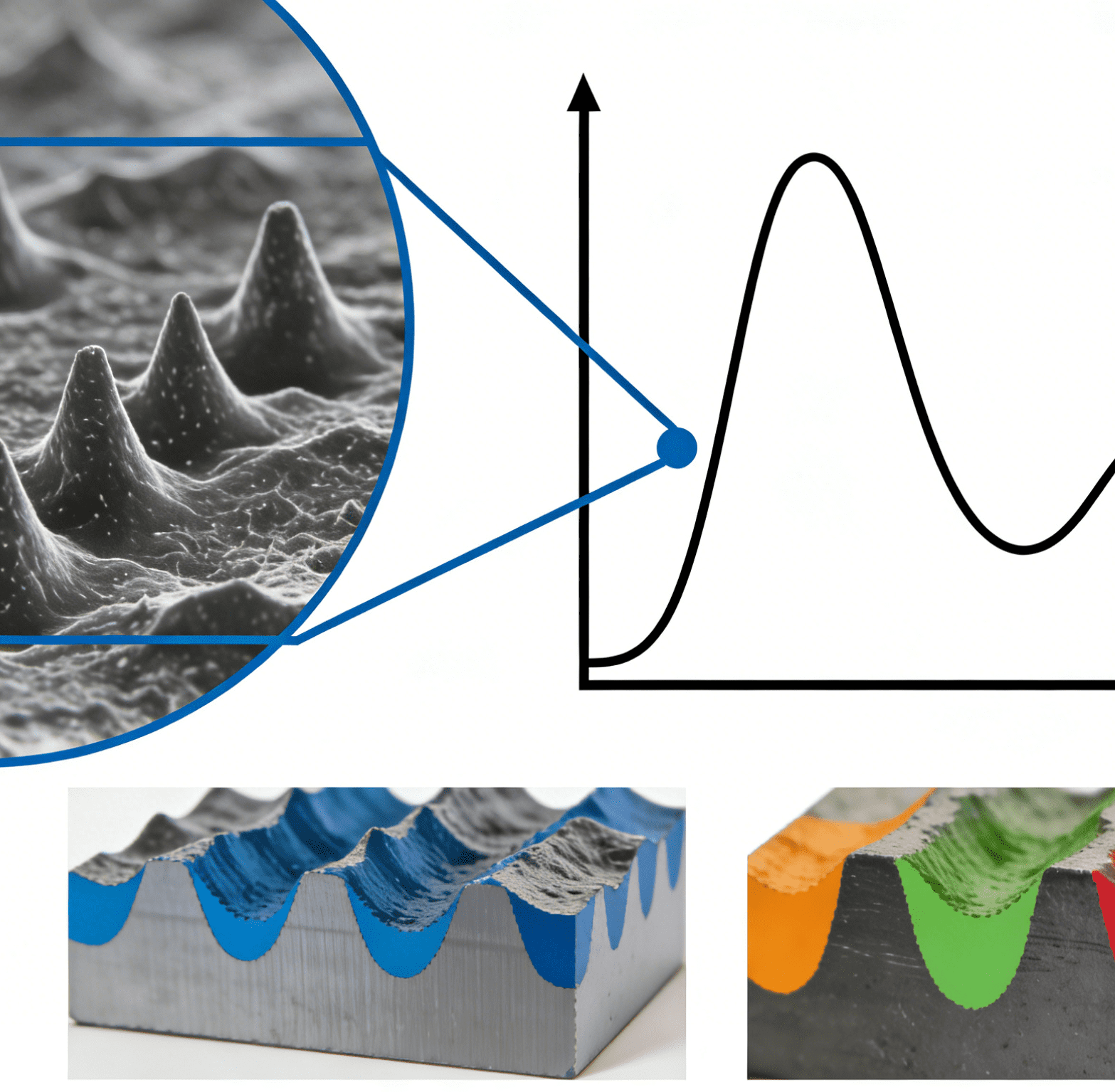

In terms of algorithms, precision digital manufacturing adopts a variety of advanced algorithms to achieve accurate machining. For example, path planning algorithms can determine the optimal movement path of machining tools on workpieces, so as to maximize machining efficiency and precision. Interpolation algorithms are used to generate a series of intermediate positions between two known points, enabling the smooth movement of machining tools and thus reducing machining errors. In addition, error compensation algorithms can monitor errors in the machining process in real time and adjust machining parameters to guarantee product precision.

Control principles also constitute a key link in precision digital manufacturing. A closed-loop control system is usually adopted, which uses sensors to monitor various parameters in the machining process in real time, such as position, speed and force, and feeds these parameters back to the controller. The controller compares the feedback information with preset target values, then calculates control signals and drives actuators to adjust the machining process. This closed-loop control ensures that the machining process is always in a stable and accurate state.

Industry Application Practice: Empowering High-Precision Medical Equipment Manufacturing

As a leader in the field of precision digital manufacturing, Ares Precision Machinery plays an important role in the medical equipment and parts industry. The manufacturing of dental equipment and supplies demands extremely high precision, because any minor error may affect patients’ comfort and treatment outcomes. With advanced programming technology and precision machining equipment, Ares Precision Machinery is capable of producing high-precision products such as dental drills and crowns. These products not only feature high dimensional accuracy but also boast excellent surface quality, meeting the needs of both dentists and patients.

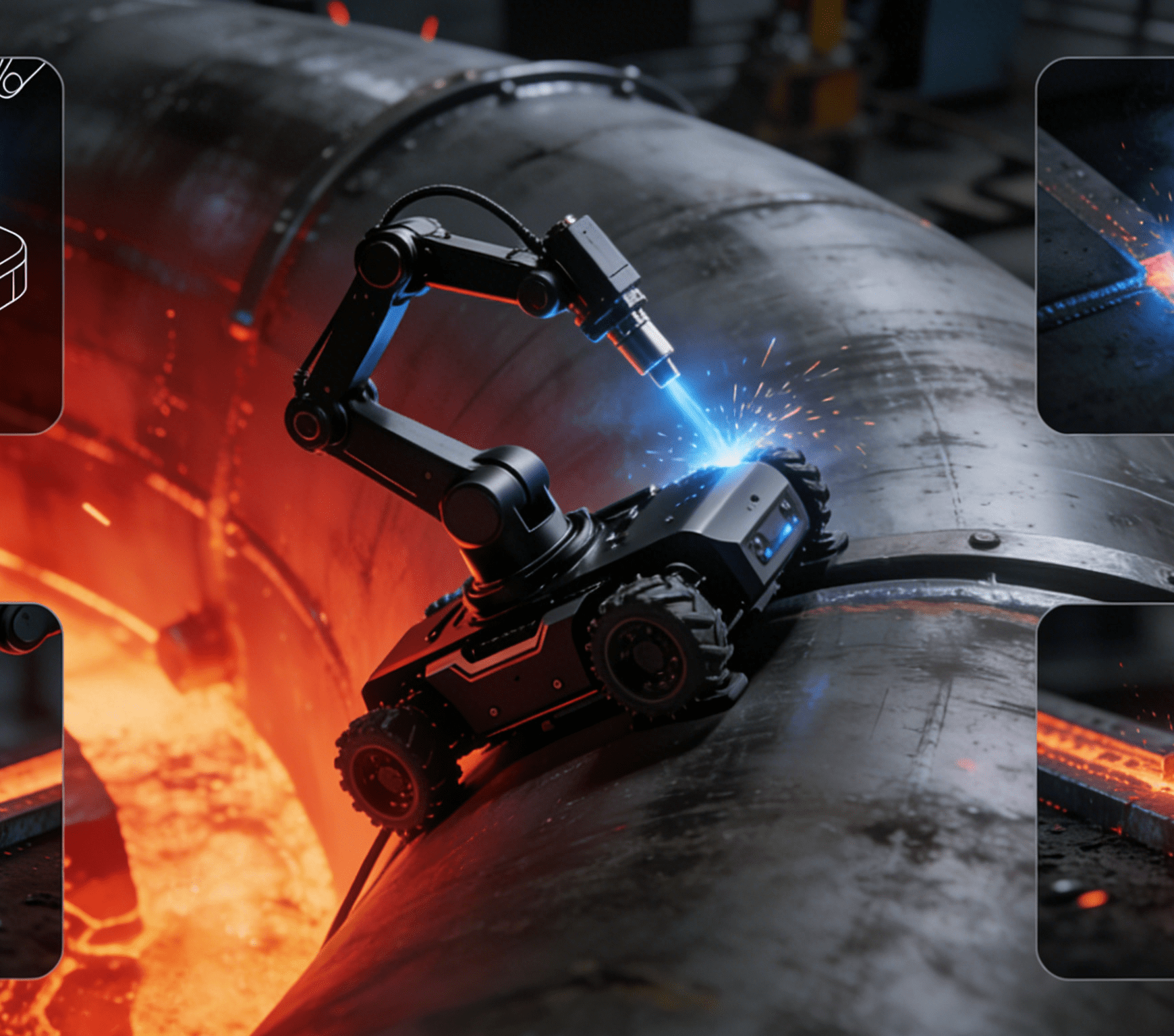

To further realize the seamless connection between high-precision machining and assembly in medical small product manufacturing, Ares Precision Machinery has integrated a 4 – Axis Robotic Small Product Assembly System into its digital production line, with programming as the core control link. This system relies on pre-written precision assembly programs to control the 4-axis flexible movement of the robot—programmers input assembly path parameters, torque thresholds and positioning accuracy requirements into the control system through specialized software, enabling the robot to complete high-precision assembly of small medical components such as dental implant accessories and miniaturized surgical instrument parts. The assembly program is also interconnected with the machining program: the machining link transmits workpiece size and surface quality data to the assembly system in real time, and the program automatically adjusts the robot’s clamping force and assembly angle to avoid assembly errors caused by machining deviations. This programming-driven “machining-assembly” integrated mode not only eliminates manual assembly errors but also improves the consistency of product assembly accuracy, fully meeting the strict quality requirements of the medical industry.

The manufacturing of medical devices also requires a high degree of precision and reliability. Medical devices are usually directly related to patients’ lives and health, so the quality requirements for such products are extremely stringent. Relying on its exquisite programming technology and strict quality control system, Ares Precision Machinery can provide high-quality parts and components for the medical device industry. For instance, in the production of surgical instruments, precise programming control ensures the sharpness, strength and durability of the instruments, providing reliable tools for doctors’ surgical operations.

Challenges and Breakthroughs: Advancing Precision Digital Manufacturing

Nevertheless, precision digital manufacturing is faced with several challenges. Firstly, the complexity of programming technology requires programmers to possess high-level professional knowledge and skills. Meanwhile, as product complexity continues to increase, the difficulty of programming also rises. Secondly, there are many sources of errors in the machining process, such as tool wear and uneven workpiece materials, which necessitate constant error compensation and optimization. In addition, the cost of precision digital manufacturing equipment is relatively high, which may be unaffordable for some small and medium-sized enterprises.

To address these challenges, researchers and engineers are constantly carrying out technological innovation and optimization. On the one hand, they are committed to developing more intelligent programming software to lower programming difficulty and improve programming efficiency. On the other hand, they are improving machining processes and equipment to reduce machining errors and enhance product quality and stability. At the same time, governments and enterprises are increasing investment in precision digital manufacturing, promoting the popularization and application of related technologies, reducing equipment costs and enabling more enterprises to benefit from it.

Precision digital manufacturing realizes accurate machining through programming, bringing enormous development opportunities to fields such as the medical equipment and parts industry. The continuous innovation and efforts of enterprises like Ares Precision Machinery will further drive the development of precision digital manufacturing technology, making greaterand worry-free contributions to the improvement of human health and quality of life.