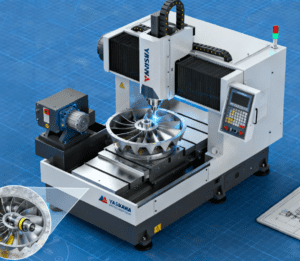

In the field of precision mechanical machining, multi-axis machining technology has attracted widespread attention. However, some question whether it is over-hyped. What is the real situation? Let us look at the outstanding performance of this technology in the industry.

3D Machining Breakthrough: Boosting Precision and Production Efficiency

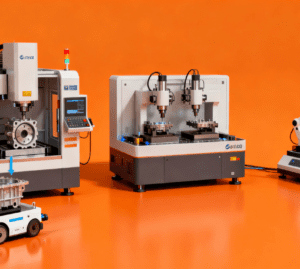

Take Aier Precision Machinery as an example. It has deeply applied multi-axis machining technology in its precision mechanical machining business, demonstrating numerous unparalleled advantages. In the manufacturing process of energy storage equipment, where extremely high machining accuracy is required for components, multi-axis machining technology shines brightly. Traditional machining methods are limited by the number of machine tool axes and can usually only perform simple planar or single-dimensional machining on workpieces. In contrast, multi-axis machining technology enables all-round three-dimensional machining. Through the coordinated operation of multiple motion axes, the cutting tool can approach the workpiece from any angle and direction, accurately shaping complex geometric forms. For instance, the special-shaped heat sinks in energy storage equipment—with their unique curved surfaces and fine heat dissipation grooves—can be machined in one go using multi-axis machine tools. This not only ensures product accuracy but also significantly improves production efficiency.

Quality Stability Enhancement: Minimizing Errors via One-Time Clamping

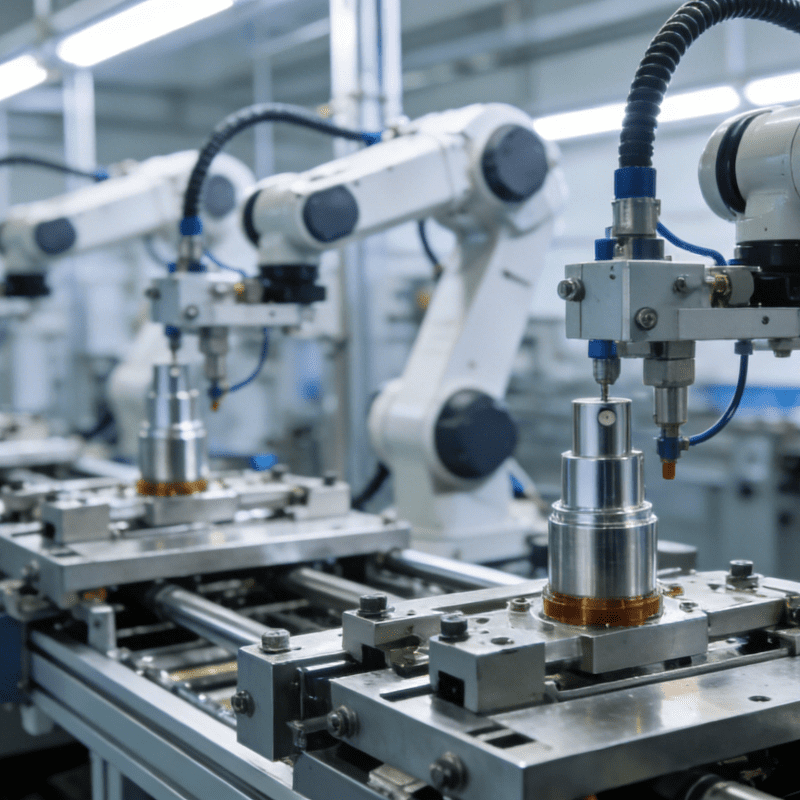

Multi-axis machining technology also plays a crucial role in enhancing the stability of product quality. For the high-precision energy storage equipment connectors produced by Aier Precision Machinery, traditional machining methods previously required multiple clamping and tool changes, which easily introduced human errors and led to product dimensional deviations. With multi-axis machining, however, a workpiece only needs to be clamped once to complete the machining of multiple surfaces and features. This reduces the number of clamping operations, minimizes error accumulation to the greatest extent, greatly improves product quality consistency, significantly lowers the rejection rate, and saves enterprises substantial costs.

Complex Design Adaptability: Meeting Miniaturization and Integration Needs

Furthermore, from the perspective of meeting complex product design requirements, multi-axis machining is undoubtedly the top choice. Today, to pursue higher performance, energy storage equipment is constantly developing toward miniaturization and integration, with increasingly complex internal structures. Relying on multi-axis machining technology, Aier Precision Machinery easily handles these complex designs. Whether it is a housing with a complex inner cavity or a transmission component with a special spiral structure, multi-axis machine tools can smoothly transform design blueprints into physical products, meeting the market’s urgent demand for high-performance energy storage equipment.

In the highly competitive precision mechanical machining market, multi-axis machining technology is not an empty hype. Through practical application, Aier Precision Machinery has fully proven that it genuinely drives industry progress, injects strong momentum into precision mechanical machining—especially in the field of energy storage equipment manufacturing—and opens a new chapter of high-precision, high-efficiency, and high-flexibility production. As technology continues to develop and improve, multi-axis machining technology will surely continue to empower industrial upgrading and help more enterprises embark on a new journey toward intelligent manufacturing.

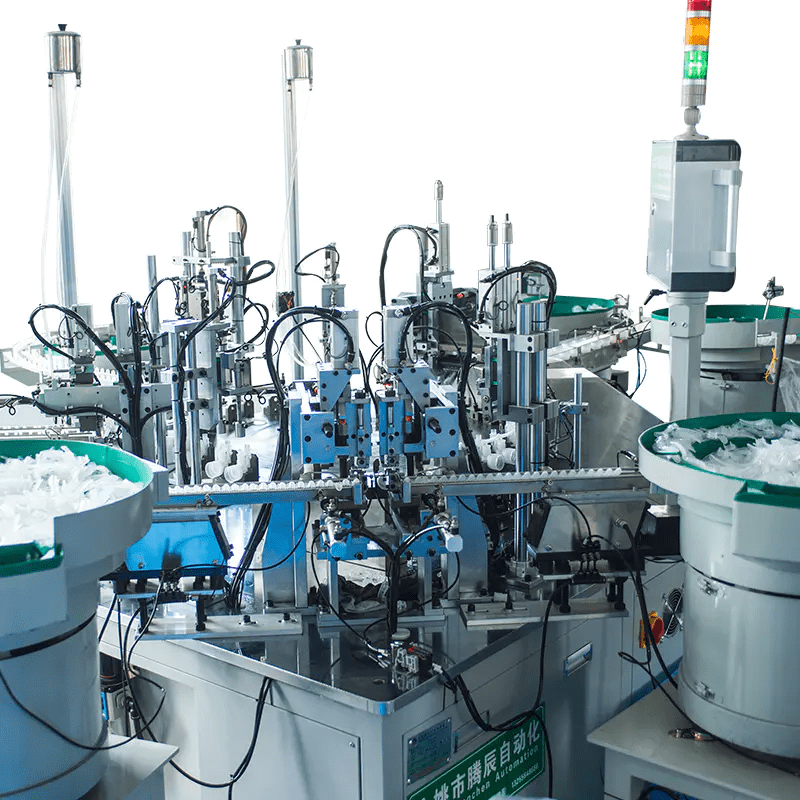

Robots realize the automated assembly of automotive connectors