by merging inkjet precision with robotic agility, the company has developed a breakthrough system that prints vivid, complex designs directly onto 3D objects—from curved automotive parts to textured helmets—ushering in a new era of digital customization for industrial production. Unveiled at Automatica 2025 in Munich, this direct-to-form printing technology marries Epson’s engineering prowess in both printing and robotics, solving long-standing challenges in decorating irregularly shaped items.

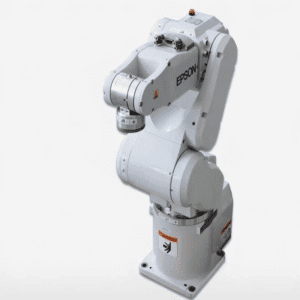

Seiko Epson Corporation’s system pairs S800 PrecisionCore inkjet heads with a six-axis articulated robot, enabling four-color and white printing on objects with intricate geometries. The S800, the smallest in Epson’s PrecisionCore lineup, excels at 600 x 600 DPI printing on 3D substrates, thanks to its compact size and independent height adjustment. Up to five heads can be positioned at varying heights to match the contours of the target object—whether it’s a household appliance, automotive component, or even apparel—ensuring consistent coverage across curves, edges, and uneven surfaces.

To tackle the distortions caused by curved surfaces, the system integrates advanced trajectory control and real-time image processing, automatically correcting alignment and color distribution. This precision eliminates the need for manual adjustments, making it feasible to mass-produce decorated 3D items with minimal errors.

Beyond graphic printing, the technology doubles as a tool for functional applications. It supports up to five colors (including white) with customizable inks, opening doors to printing conductive sensors for electronics or specialized coatings for industrial parts. By replacing analog processes—such as masking, painting, or labeling—with a fully digital workflow, Epson’s system reduces reliance on specialized tools, cuts down on material handling, and shrinks production line footprints.

Sustainability is another key advantage: localized inkjet printing minimizes ink usage and waste compared to traditional methods, aligning with Epson’s commitment to eco-friendly manufacturing.

Epson is now seeking global partnerships to scale the solution, offering a turnkey package that includes hardware, ink formulations, image processing software, and technical support. For European clients, a permanent demonstration hub will open at Epson Deutschland in Düsseldorf starting July 2025, serving as a testing ground for custom materials and applications.

This fusion of inkjet and robotics isn’t just a technical feat—it’s a catalyst for industrial creativity. By enabling high-precision, on-demand printing on 3D forms, Epson empowers manufacturers to rethink design possibilities, reduce time-to-market, and embrace sustainable practices. As industries increasingly demand customization and efficiency, this innovation positions Epson at the forefront of bridging digital design and physical production, proving that the future of manufacturing lies in the seamless integration of seemingly disparate technologies.

What are the application cases of Epson robots in the industrial field?