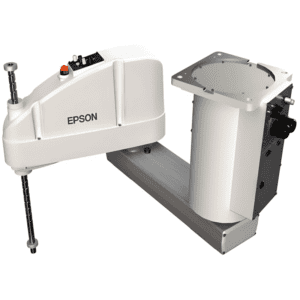

its first industrial collaborative robot with fully integrated vision guidance. This next-generation solution merges Epson’s precision robotics expertise with intelligent visual perception, creating a system that doesn’t just operate—it sees and adapts. Designed to redefine automation in dynamic environments like manufacturing, logistics, and life sciences, the robot enables safer, faster, and more flexible workflows where human-robot collaboration is seamless and intuitive.

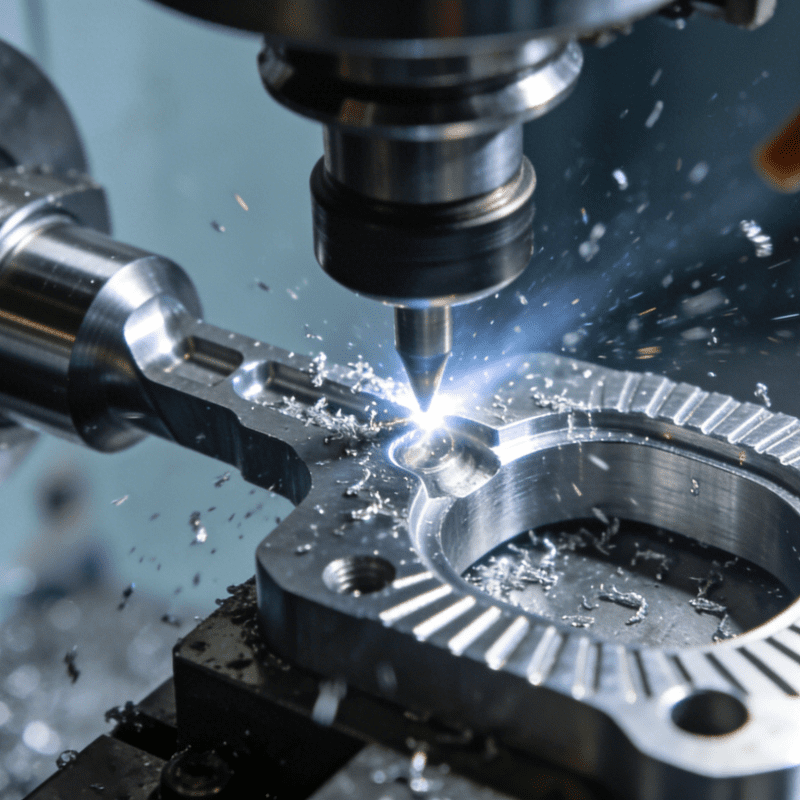

At the core of this innovation is the Epson AX6-A901S, a 6-axis collaborative robot that unites hardware and vision software in a single, cohesive package. Epson’s industry-proven Vision Guide system serves as the robot’s “eyes,” allowing it to perceive its surroundings in real time: identifying parts, adjusting to variations in shape or position, and executing intricate tasks with unmatched accuracy. Whether inspecting microcomponents under tight tolerances or guiding high-speed pick-and-place operations, the robot leverages visual data to make split-second decisions, eliminating the need for rigid, pre-programmed paths.

Volker Spanier, Head of Robotics at Epson Europe, emphasizes the transformative nature of this integration: “In modern automation, vision isn’t an afterthought—it’s the foundation of adaptability. Our collaborative robot is engineered from the ground up to interact visually with its environment, ensuring precision and safety even in settings where cleanliness, accuracy, and flexibility are non-negotiable, like pharmaceutical labs or electronics manufacturing.”

Key Features Redefining Collaborative Automation

- Integrated Vision Excellence: Powered by Epson Vision Guide, the system supports up to six cameras, enabling high-accuracy part detection, detailed inspection, dimensional gauging, and barcode reading—all without external add-ons.

- Human-Centric Safety: Built for close human collaboration, the AX6-A901S features real-time collision sensing and clean-room compatible construction, making it suitable for sensitive sectors like biotech and pharmaceuticals.

- Compact Powerhouse: With a 6 kg payload and 900 mm reach, its lightweight design and space-saving controller integrate seamlessly into tight workspaces, including mobile platforms like AGVs and AMRs.

- Universal Adaptability: Compatible with 100–230 VAC and 48 VDC power sources, it thrives in diverse environments, from factory floors to laboratory benches.

- Accessible Programming: Python-based coding simplifies customization, allowing developers and integrators to tailor workflows without specialized robotics expertise—accelerating deployment and scaling.

From identifying misshapen parts on a fast-moving conveyor to handling delicate lab samples with micron-level precision, Epson’s new collaborative robot represents a shift in automation: machines that don’t just follow commands, but perceive context. This fusion of vision and robotics empowers businesses to tackle complex, variable tasks that once required human dexterity—all while working safely alongside their teams.

Sales of the Epson AX6-A901S will begin in autumn 2025. Until then, visitors can experience the robot live at Automatica 2025 in Hall B5, Stand 311 at Messe München—where the future of seeing, adapting, and collaborating is already in motion.