In the sanitary ware industry, the bathroom shower head — a daily-se product closely tied to quality of life — has evolved from a single-function “water outlet tool” to a multi-scenario product integrating constant temperature control, water-saving atomization, and intelligent sensing. However, behind this product upgrade, the traditional manual assembly mode has long been a bottleneck restricting industry development: manual installation of components such as shower heads, hoses, interface valves, and gaskets often faces problems like inconsistent torque (leading to water leakage), misaligned assembly (affecting water flow uniformity), and low efficiency (a skilled worker can only assemble 80-100 units per day). With the surge in market demand for personalized shower products (such as constant-temperature, anti-clogging, and multi-mode spray types) and the tightening of labor costs, bathroom shower head assembling machines have emerged as a core solution to achieve “high efficiency, high precision, and flexible production” in the sanitary ware industry.

- Core Composition of Bathroom Shower Head Assembling Machines: Building a Closed-Loop Automation System

A mature bathroom shower head assembling machine is not a single mechanical device, but a systematic solution integrating “feeding, positioning, assembling, detecting, and data management.” Its core modules are designed to address the diverse assembly needs of shower heads (such as different interface sizes, material combinations, and functional components) while ensuring consistency and reliability.

- Multi-Category Material Feeding Unit: Solving “Mixed Component” Supply Challenges

Shower head assembly involves up to 10 types of components, including plastic shower bodies, metal interfaces (G1/2, G3/4 specifications), silicone gaskets, filter screens, hoses, and constant-temperature valves. The feeding unit adopts a “classified conveying + anti-misfeeding” design to avoid confusion:

For small standard parts (gaskets, filter screens): Vibratory bowls with customized guide rails are used, and the inner wall of the bowl is coated with Teflon to prevent silicone gaskets from sticking; a photoelectric sensor at the outlet checks the orientation of parts, and reversely placed gaskets are blown out by an air nozzle, ensuring a feeding qualification rate of over 99.8%.

For large components (shower heads, hoses): Belt conveyors with positioning jigs are used, and each component is attached with a QR code to record its model and batch, which is scanned by a code reader at the feeding port to confirm it matches the current production order (preventing wrong material feeding).

For precision parts (constant-temperature valve cores): Vacuum suction cups with pressure sensors are used for feeding, and the suction force is adjusted according to the weight of the valve core (e.g., 5N for plastic valve cores, 12N for metal valve cores) to avoid damage to the internal thermal sensitive elements.

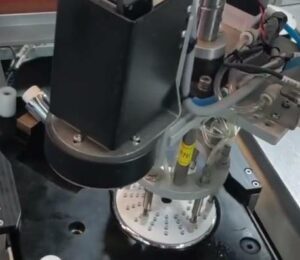

- Visual-Guided Precision Assembly Unit: Guaranteeing “Zero Leakage” Assembly Quality

Water leakage is the most common quality problem of shower heads, which is mostly caused by improper assembly (such as uneven gasket compression or incomplete thread engagement). The assembly unit relies on “visual positioning + torque control” to solve this pain point:

Dual-camera visual guidance: A top-mounted high-resolution camera (20 million pixels) captures the position of the shower head interface, and a side-mounted camera identifies the thread direction of the metal connector; the system calculates the assembly deviation in real time (accuracy ±0.02mm) and guides the six-axis collaborative robot to adjust the angle, ensuring the connector is aligned with the interface at a coaxiality of ≤0.05mm.

Intelligent torque control: For threaded connections (such as shower head and interface), a torque sensor integrated at the end of the robot monitors the tightening force in real time. For example, the torque for plastic interfaces is set to 1.2-1.5 N·m (to avoid cracking), and for metal interfaces to 2.0-2.3 N·m (to ensure sealing); when the torque reaches the preset value, the robot automatically stops rotating, preventing over-tightening or under-tightening.

Flexible pressing for gaskets: For silicone gaskets that need to be pressed into the interface groove, a servo electric cylinder with force feedback is used. The pressing force is controlled at 8-10N, and the pressing depth is monitored by a laser displacement sensor (to ensure the gasket is fully seated in the groove, avoiding water seepage caused by incomplete fitting).

- Multi-Dimensional Quality Detection Unit: From “Assembly Completion” to “Qualified Confirmation”

The detection unit targets the core quality risks of shower heads (sealing, appearance, and functional performance) and implements three-level inspection:

Sealing detection: After assembly, the shower head is connected to a pressure test pipeline, and the system injects water at 0.8MPa (simulating the standard household water pressure). If the pressure drop within 30 seconds exceeds 0.02MPa, it is judged as a leak (most likely due to a missing gasket or improper torque), and the unqualified product is pushed to the rejection area by a pneumatic push rod.

Appearance detection: An AI vision system with self-trained models checks for surface defects (scratches on the shower head, burrs on the interface) and assembly defects (hose misalignment, missing filter screens). The recognition accuracy for scratches ≥0.3mm in length reaches 99.5%, which is far higher than manual visual inspection (about 85%).

Functional sampling inspection: For constant-temperature shower heads, 5% of the products are randomly selected for functional testing: the water temperature is adjusted from 35℃ to 50℃, and the system checks whether the outlet water temperature stabilizes within ±1℃ (meeting national standards) and whether the anti-scald function is triggered when the water temperature exceeds 55℃.

- Digital Central Control System: Realizing “Full-Process Traceability”

The system adopts a “PLC + industrial touch screen + MES integration” architecture, which not only realizes real-time control of the assembly process but also builds a data closed loop:

Production monitoring: Operators can view key data such as current production speed (up to 300 units/hour for standard models), pass rate, and equipment utilization rate on the touch screen; when a fault occurs (such as material shortage or robot jamming), the system automatically sends an alarm to the manager’s mobile app and provides a troubleshooting guide (e.g., “Check the vibratory bowl for gasket blockage”).

Data traceability: Each shower head is assigned a unique serial number, which is linked to assembly data (torque value, pressure test result, inspector) and component batch information (shower head material, valve core supplier) in the MES system. If a after-sales leak occurs, the enterprise can trace back to the specific production line, time, and even the torque parameter of the robot at that time within 10 seconds, facilitating root cause analysis.

Quick changeover: For different types of shower heads (e.g., switching from a handheld shower to a top-spray shower), operators only need to select the corresponding product model on the touch screen; the system automatically calls the preset feeding parameters (vibratory bowl frequency, conveyor speed), assembly parameters (torque, pressing force), and detection standards, and the changeover can be completed within 5 minutes (compared to 2-3 hours for manual adjustment of mechanical structures).

- Key Technological Breakthroughs: Breaking Through the “Flexibility + Precision” Dilemma

The popularization of bathroom shower head assembling machines is not a simple “mechanical replacement of labor,” but relies on three core technological breakthroughs to adapt to the diversified and personalized production needs of the sanitary ware industry.

- Multi-Specification Adaptive Technology: From “Single Model” to “One Machine for Multiple Products”

Traditional automatic equipment can only assemble a single type of shower head, and when switching models, it is necessary to replace mechanical jigs and adjust transmission shafts — a time-consuming and labor-intensive process. The new generation of assembling machines solves this problem through “parameterization + modularization”:

Parameterized control: The system stores the assembly parameters of 50+ common shower head models (such as interface diameter, torque range, and pressing depth) in the database. When producing a new model, it only needs to input the 3D drawing parameters of the product, and the system automatically calculates the optimal assembly path and detection standards (no need for manual programming).

Modular jigs: The positioning jigs for shower heads adopt a quick-change design (using magnetic adsorption + pin positioning). When switching models, operators only need to replace the jig plate (weight ≤2kg) instead of the entire jig structure, and the changeover time is reduced from 2 hours to 5 minutes. For example, a leading 卫浴 enterprise in Guangdong uses this technology to produce 8 types of shower heads on one assembly line, and the equipment utilization rate is increased from 60% to 92%.

- Intelligent Sealing Detection Technology: From “Post-Inspection” to “In-Process Prevention”

Traditional manual assembly often relies on “water testing after assembly” to check for leaks, which not only wastes water resources but also cannot identify the root cause of leaks (e.g., whether it is due to a gasket defect or improper torque). The intelligent sealing detection technology realizes “prevention in advance + accurate positioning of problems”:

Pre-assembly gasket inspection: Before the gasket is fed into the assembly station, a laser thickness gauge measures its thickness (tolerance ±0.05mm). If the thickness is too thin (leading to insufficient compression) or too thick (leading to difficulty in assembly), the gasket is automatically rejected, avoiding subsequent leakage caused by unqualified parts.

Real-time torque curve monitoring: During the thread tightening process, the system records the torque change curve in real time. If the curve is abnormal (e.g., the torque suddenly drops in the middle, indicating thread slipping), the assembly is immediately stopped, and the system prompts “Check the thread of the connector,” preventing defective products from entering the next process. A test by a Zhejiang sanitary ware factory shows that this technology reduces the leak rate of shower heads from 3.5% (manual assembly) to 0.12%.

- Human-Machine Collaborative Safety Technology: Balancing “Automation” and “Operational Flexibility”

In small-batch customized production (e.g., high-end shower heads with personalized engravings), it is sometimes necessary for workers to manually place special components (such as custom decorative rings) into the assembly line. The human-machine collaborative safety technology ensures the safety of operators while maintaining production efficiency:

Safety light curtain + pressure-sensitive floor: A safety light curtain is installed around the robot working area. If a worker’s hand enters the area, the robot immediately reduces its speed to 10% of the original speed; if the hand continues to approach, the robot stops completely. The pressure-sensitive floor under the assembly line also triggers an emergency stop if a worker steps on it by mistake.

Collaborative robot with force feedback: The six-axis robot uses a collaborative model with a maximum operating force of 30N. Even if it accidentally touches a worker, it will not cause injury (meeting the ISO/TS 15066 human-machine collaboration standard). For example, when assembling a custom shower head, the worker can manually place the decorative ring into the positioning jig, and the robot will automatically continue the subsequent assembly steps after detecting that the worker’s hand has left — realizing “man-machine collaboration without isolation barriers.”

III. Industry Application Practices: Tailoring Solutions for Different Scenarios

Bathroom shower head assembling machines are not “one-size-fits-all” equipment. They need to be customized according to the product type, production scale, and quality requirements of sanitary ware enterprises. Below are three typical application scenarios:

- Large-Scale Mass Production: Household Ordinary Shower Heads

For enterprises with a daily output of over 5,000 shower heads (such as mainstream sanitary ware brands), the focus is on “high efficiency and low cost.” The assembly line adopts a “multi-station parallel” design:

6 assembly robots work simultaneously, each responsible for one process (e.g., robot 1 installs gaskets, robot 2 tightens interfaces, robot 3 connects hoses); the conveyor belt uses a “pulsating flow” mode to transfer products between stations, with a beat time of 12 seconds per unit.

The feeding system uses a “centralized storage + automatic replenishment” mode: a 3-meter-high silo stores shower heads and interfaces, and when the material level in the vibratory bowl is lower than the set value, the system automatically replenishes materials through a lifting conveyor, realizing 24-hour continuous production without manual material addition.

Application effect: A Fujian sanitary ware enterprise replaced 20 manual workers with 2 assembly lines (12 robots in total), and the daily output increased from 1,800 units to 6,000 units; the labor cost per unit decreased from 12 yuan to 3 yuan, and the leak rate dropped from 4.2% to 0.15%.

- Medium-Batch Custom Production: Constant-Temperature and Intelligent Shower Heads

Constant-temperature shower heads (with built-in temperature-sensing elements) and intelligent shower heads (with Bluetooth control functions) have high assembly precision requirements and frequent model changes. The assembly machine focuses on “precision and flexibility”:

For the assembly of constant-temperature valve cores: A visual system with 3D imaging function is used to check the alignment of the valve core and the water inlet (required to be within ±0.03mm), and a torque wrench with a precision of 0.01 N·m is used to tighten the fixing screws to avoid damaging the internal thermal sensitive components.

For the assembly of intelligent modules (Bluetooth chips): A laser soldering machine integrated with the robot is used to solder the chip pins to the shower head circuit board, with a soldering temperature controlled at 220±5℃ (to prevent chip overheating) and a soldering spot inspection rate of 100% (using AI vision to check for cold joints or missing soldering).

Application effect: A Shanghai intelligent sanitary ware enterprise uses this equipment to produce 8 types of constant-temperature shower heads, with a model changeover time of 5 minutes; the qualified rate of temperature control accuracy (±1℃) reaches 99.2%, which is 15 percentage points higher than manual assembly.

- Small-Batch High-End Production: Luxury Custom Shower Heads

For high-end shower heads (e.g., imported stainless steel shower heads with engraved patterns, priced over 2,000 yuan per unit), the focus is on “quality and traceability.” The assembly machine is equipped with a “high-precision detection + full-process data recording” system:

Appearance 3D scanning: After assembly, a 3D scanner with a point cloud density of 0.02mm scans the entire shower head to check for scratches (≥0.1mm is considered unqualified) and engraving pattern clarity (ensuring no blurring or missing strokes).

Full-life cycle data recording: Each shower head’s serial number is linked to not only assembly data but also raw material information (e.g., stainless steel grade, engraving machine parameters) and testing data (e.g., 10,000 times of switch fatigue testing results). Consumers can query the entire production and testing process by scanning the QR code on the product.

Application effect: A Guangzhou luxury sanitary ware brand uses this equipment to produce 300-500 custom shower heads per day, with a product qualification rate of 99.8%; the after-sales complaint rate (mainly about appearance defects) dropped from 8% to 0.3%, and the brand’s premium capacity increased by 20%.

- Future Development Trends: Toward “More Intelligent, Greener, and More Integrated”

With the deepening of industrial intelligence and the upgrading of consumer demand, bathroom shower head assembling machines will develop in three directions:

- AI-Driven Predictive Maintenance: Reducing Unplanned Downtime

In the future, the system will be equipped with more than 20 types of sensors (monitoring robot joint temperature, vibratory bowl amplitude, torque sensor drift, etc.) and use AI algorithms to analyze equipment health status:

For example, if the amplitude of the vibratory bowl increases by 15% compared to the normal value, the system judges that the internal guide rail is worn and sends a “replace guide rail within 24 hours” reminder to the maintenance personnel; if the torque sensor’s measurement error exceeds 3%, it automatically calibrates the sensor (without stopping production).

According to industry data, predictive maintenance can reduce equipment unplanned downtime by 40% and maintenance costs by 30%, which is crucial for enterprises that rely on continuous production.

- Green Energy-Saving Design: Responding to Environmental Protection Requirements

Against the background of global carbon neutrality, assembling machines will pay more attention to energy conservation:

Energy-saving motors: The robot and conveyor belt use permanent magnet synchronous motors with an energy efficiency rating of IE4 (higher than the current IE3 standard), reducing energy consumption by 15% during operation.

Water recycling in detection: The water used for sealing pressure testing is filtered (through a 5-micron filter) and disinfected, then recycled to the pressure test pipeline, reducing water consumption by 80% compared to one-time use.

Low-power standby: When the equipment is in standby mode (e.g., between production orders), the system automatically shuts down non-essential modules (such as 3D scanners and laser soldering machines) and reduces the robot’s power supply to standby mode, with standby power consumption reduced from 500W to 50W.

- Integration with the Whole Industry Chain: From “Assembly” to “End-to-End Intelligent Manufacturing”

The assembling machine will no longer be an independent equipment, but will be integrated with upstream raw material supply (e.g., plastic injection molding) and downstream packaging and logistics to form a “smart factory” ecosystem:

Upstream connection: The MES system of the assembling machine is connected to the injection molding machine’s production system. When the injection molding machine produces shower heads of a certain model, it automatically sends the batch information to the assembling machine, which pre-adjusts the assembly parameters (realizing “seamless connection between molding and assembly”).

Downstream connection: After the shower head is assembled and qualified, it is automatically transferred to the packaging station by an AGV; the packaging machine scans the product serial number, prints the corresponding label (including production date, batch, and quality inspection result), and packs it into a carton. The logistics system then automatically generates a shipping order according to the order information, realizing “from raw material to finished product delivery” full-process automation.

Conclusion: The “Invisible Engine” of Sanitary Ware Industry Upgrading

The bathroom shower head assembling machine may not be as eye-catching as intelligent shower products themselves, but it is the “invisible engine” driving the sanitary ware industry to move from “labor-intensive” to “technology-intensive.” It not only solves the traditional pain points of low efficiency and poor quality consistency but also provides technical support for enterprises to respond to personalized market demand (such as small-batch custom products) and green production requirements.

In the future, as technologies such as AI, digital twin, and human-machine collaboration continue to penetrate, bathroom shower head assembling machines will become more “smart” and “flexible,” helping the sanitary ware industry achieve higher-quality development. For consumers, this means more reliable, personalized, and cost-effective shower products; for enterprises, it means stronger competitiveness in the global market. This is the true value of intelligent automation — not just replacing labor, but creating a better industrial ecology and consumer experience.