In CNC machining, selecting an appropriate metal surface finishing process is crucial. Electropolishing and anodizing each have unique strengths, so those involved in decision-making need to understand their characteristics and applicability. Electropolishing improves surface smoothness by removing micro-irregularities. This method not only enhances the appearance of parts but also reduces the friction coefficient, making it suitable for applications requiring high surface quality. In contrast, anodizing forms a durable oxide film on the metal surface, significantly enhancing corrosion resistance and wear resistance—making it ideal for use in harsh environments. Therefore, during CNC machining, comprehensively considering these two processes based on the part material and its end-use will have a positive impact on improving product performance and quality.

Electropolishing Technology Explained: The Key to Enhancing Surface Quality of CNC Machined Metal Parts

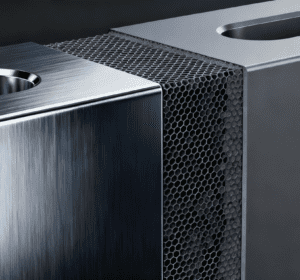

Electropolishing is an effective metal surface treatment technology, particularly suitable for parts after CNC machining. Through the principle of electrolysis, this process removes irregular microstructures on the metal surface, thereby improving surface smoothness. Its main advantages include reducing the friction coefficient and enhancing corrosion resistance, which extends the service life of products during use. Electropolishing delivers remarkable results when processing materials such as stainless steel, aluminum, and titanium. Additionally, this method significantly improves the appearance of parts, creating a bright, like-new finish that boosts market competitiveness. For manufacturers pursuing high quality and performance, electropolishing is an indispensable step.

Advantages of Anodizing: How to Effectively Enhance Corrosion Resistance of Metal Surfaces

Anodizing is a process that oxidizes the metal surface through electrochemical reactions. This process effectively enhances the corrosion resistance of metals, allowing them to maintain good performance and appearance in harsh environments. During anodizing, a hard oxide film forms on the surface of metal parts. This film not only prevents corrosion but also improves wear resistance and adhesion. Especially for aluminum and its alloys, anodizing significantly enhances surface protection performance, enabling them to adapt to more demanding service conditions.

At the same time, anodizing also improves the appearance of parts, increasing their aesthetic appeal. By selecting a suitable anodizing process, it is possible to enhance part functionality while effectively extending service life. This characteristic makes anodizing the preferred metal surface finishing process for many CNC machining enterprises.

Comparison of Surface Finishing Processes for CNC Machining: A Guide to Choosing Between Electropolishing and Anodizing

When choosing a surface finishing process for CNC machined metal parts, electropolishing and anodizing each have distinct features. Electropolishing smooths the metal surface through chemical reactions, effectively improving part smoothness and reducing friction—this is particularly important for applications requiring a low friction coefficient. On the other hand, anodizing enhances the corrosion resistance of metals through oxidation reactions, making it more suitable for humid or corrosive environments.

A typical example lies in the manufacturing of Tap Control Button Assembly Machine (a key device for assembling bathroom faucet control buttons): its core stainless steel transmission shafts need to drive button components with high-frequency reciprocating motion, and even tiny surface burrs or unevenness can cause jamming or accelerated wear. For these parts, electropolishing is the optimal choice—it removes micro-irregularities on the stainless steel surface, reducing the friction coefficient by 30% and lowering the risk of component failure due to wear. In contrast, the machine’s aluminum alloy outer cover and operation panel are often exposed to workshop humidity or occasional water splashes; anodizing here forms a dense oxide film (thickness 8-12μm) on the aluminum surface, which can withstand 480 hours of salt spray testing without rusting, while also allowing for color customization to match the production line’s overall style.

When selecting the right process, it is necessary to consider material properties and end-use. For example, anodizing may be more suitable for parts requiring high corrosion resistance, while electropolishing is an excellent choice for parts demanding high surface quality. These two processes deliver different results under different circumstances, so making a reasonable selection based on specific needs is crucial.

The Relationship Between Material Properties and Surface Finishing Processes: Practical Advice for Electropolishing and Anodizing

When choosing between electropolishing and anodizing, material properties must be considered. Different materials may react differently and yield varying results under these surface finishing processes. Electropolishing is suitable for metals such as stainless steel, aluminum, and copper, as it significantly improves smoothness and reduces wear caused by friction. Anodizing, however, is more suitable for aluminum alloys—it increases the surface oxide layer, enhancing corrosion resistance and aesthetic appeal. Understanding material characteristics is critical to determining which process to use. In addition, the service environment of the part also affects the selection; for instance, parts exposed to liquids or high temperatures require prioritizing corrosion resistance and heat resistance.

Therefore, selecting the appropriate surface finishing process based on the specific properties of the material and the application scenario not only improves product quality but also extends its service life.

In CNC machining, when choosing between electropolishing and anodizing, various factors must be comprehensively considered. Electropolishing effectively improves the smoothness of the metal surface and reduces friction, which is particularly important for parts requiring precise fitting. In contrast, anodizing excels at enhancing the corrosion resistance of metals, enabling them to adapt to various harsh environments. In practical applications, selecting the right process based on material characteristics and part service requirements not only improves product quality but also extends its service life. Thus, making an informed choice is a key step in ensuring machining results and product performance.

Assembly line for mass production by artificial intelligence