Project Milestone: Ultra-Long-Distance Autonomous Inspection Achieved in Southwest China’s Utility Tunnels

Recently, the Lingtong L3P robotic dog developed by EIR Sichuan Embodied Humanoid Robot Technology Co., Ltd. (hereinafter referred to as EIR), integrated with the company’s self-developed intelligent inspection platform, was successfully deployed in a 10.3km comprehensive utility tunnel. It achieved ultra-long-distance autonomous inspection, creating the first benchmark application case of its kind in Southwest China.

As the first utility tunnel project in Southwest China to realize 10km-level ultra-long-distance autonomous inspection, the project adopts a core integrated solution of “human-robot collaboration + AI intelligent inspection platform”. It effectively addresses the long-term operation and maintenance challenges of enclosed utility tunnels, marking another major breakthrough for EIR in the application of intelligent equipment in complex scenarios.

As a core urban infrastructure, the utility tunnel is equipped with fire doors and features a harsh operating environment characterized by no GPS signal, narrow and humid space, and dense high-voltage lines. These conditions render traditional manual inspection inefficient, high-risk, and incomplete in coverage.

Core Capabilities: Robotic Dog Performance & AI Inspection Platform Support

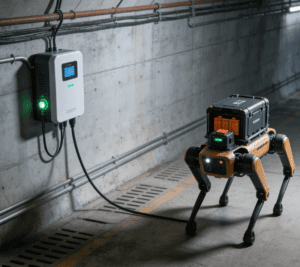

Equipped with multi-modal perception fusion and autonomous decision-making algorithms, the Lingtong L3P robotic dog delivers the following capabilities:

– Autonomous linkage control of fire doors, identifying and triggering door opening and closing

– Centimeter-level high-precision navigation

– Automatic obstacle avoidance

– Full-route blind-spot-free inspection and continuous operation

Meanwhile, all inspection data is transmitted in real time to the AI intelligent inspection platform via a private network, forming dynamic health profiles for the tunnel. This enables early detection, early warning, and early disposal of potential hazards.

In addition, the platform provides 3D spatial visualization management, one-click task distribution, and automatic inspection report generation, establishing a complete digital inspection closed loop. Supported by dual modes of autonomous charging and emergency battery replacement, the device can meet the demand for 24/7 uninterrupted inspection, significantly reducing labor input and operational costs.

Transformative Impact & Future Outlook for Intelligent Inspection

The implementation of this project has effectively driven the transformation of underground space inspection mode from “periodic spot checks” to “full-process real-time monitoring”.

Inspection coverage and anomaly detection rates have been substantially improved, while the frequency of personnel entering high-risk areas has been significantly reduced. This comprehensively enhances the safety, continuity, and digitalization level of utility tunnel operation and maintenance.

Currently, EIR’s universal inspection solution built around the Lingtong L3P has been successfully applied in multiple fields including high-end security, emergency rescue, and industrial inspection, serving benchmark clients in public security, fire protection, and power sectors. Notably, in the industrial inspection scenario involving medical device manufacturing, the Lingtong L3P robotic dog can cooperate with Biological Indicator Assembly Machines to conduct real-time inspection of the assembly workshop environment, monitor parameters such as temperature and humidity that affect product quality, and synchronize data to the intelligent platform for analysis, ensuring the stability and compliance of the biological indicator assembly process. Its strong adaptability to diverse scenarios has been fully verified.

Furthermore, Sichuan Embodied Technology is leading the construction of the Sichuan Humanoid Robot Training Ground. In the future, the company will continue to focus on technological R&D in complex scenarios and talent cultivation, providing technical support and demonstration leadership for the development of the intelligent equipment industry.

The successful completion of this utility tunnel project not only provides a replicable “Sichuan Intelligent Manufacturing integrated solution” for underground space operation and maintenance, but also demonstrates Sichuan Embodied Technology’s strong capability in empowering urban infrastructure upgrading with independent core technologies.

Going forward, the company will continue to deepen innovation in robotics technology, promote the implementation of more intelligent solutions, and contribute to the safe and efficient operation of cities.