Simply put, Electrical Discharge Machining (EDM) is a “dialogue” between electrical energy and metal. Imagine a pair of well-coordinated “electric spark partners” — the electrode (usually made of copper or graphite) and the workpiece maintain a tiny gap. Driven by a pulsed power supply, instantaneous high-temperature electric sparks are continuously generated between them. These visible “miniature lightning bolts” act like tiny drills, instantly melting or even vaporizing the metal material at the contact points. Through the accumulation of countless precise electrical erosions, the preset shape is finally “drawn” on the surface of the workpiece. The entire process requires no direct contact between the cutting tool and the workpiece, similar to pyrography (art created by burning patterns onto materials), achieving non-contact engraving through precise control of energy.

The magic of this machining method lies in two key aspects:

It is not limited by material hardness. Whether it is hardened steel (as hard as diamond) or titanium alloy (with an extremely high melting point), any conductive material can become its “canvas”.

Its machining accuracy can be controlled at the micrometer level (equivalent to 1/100 the diameter of a human hair), allowing even fine textures and complex cavities on metal surfaces to be presented with precision.

Application Scenarios: An All-Round Craftsman from Precision Molds to Aerospace Parts

In the arena of industrial manufacturing, EDM is a well-deserved “all-rounder” with wide-ranging applications:

Mold Machining

It is the “soul shaper” of injection molds and die-casting molds. When molds require the machining of deep narrow grooves, thin-walled structures, or complex curved surfaces (such as the streamlined grooves of automotive panel molds), traditional milling struggles to perform. However, EDM, relying on the flexible shaping of electrodes, can carve high-precision cavities into hard mold steel like an embroidery needle — ensuring that the subsequent plastic or metal parts produced have smooth surfaces and precise dimensions.

Precision Component Machining

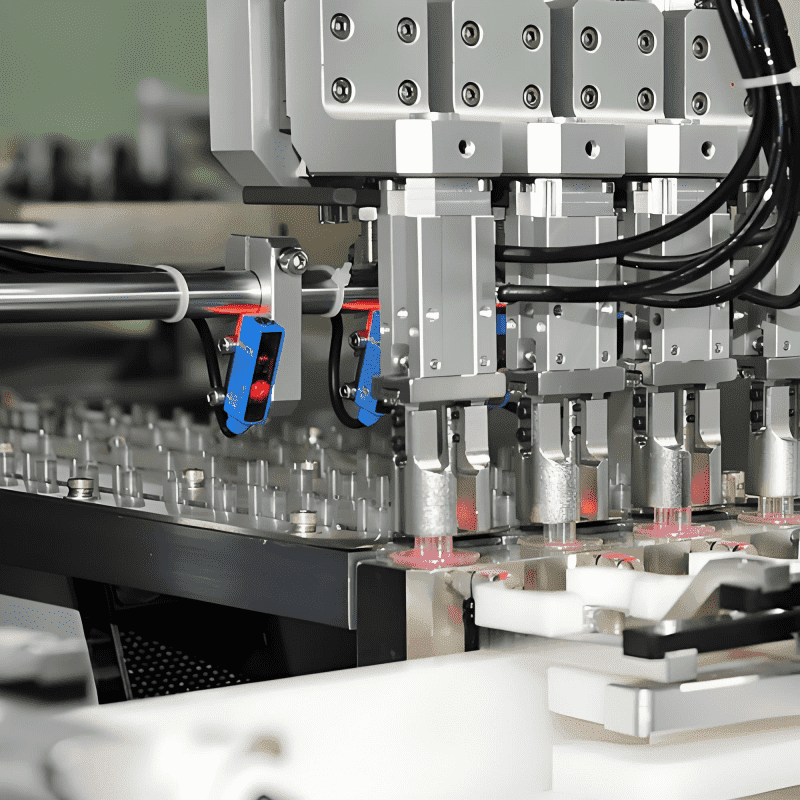

In fields such as watches and electronic components, it acts as a “micrometer-level engraver”. For example, when machining micro-holes with a diameter of 0.1 mm (thinner than a human hair), or gears and threads with extremely high precision requirements, EDM uses point-by-point electrical discharge to avoid vibration errors in mechanical machining. This allows even small components to achieve the same precision as large-scale heavy machinery.Notably, the miniature electronic components processed by EDM — such as high-precision sensor chip bases and micro-connector contacts — rely on Automatic placement machines (auto mounters) for efficient and precise assembly in subsequent mass production. Equipped with high-resolution visual positioning systems and ultra-fine suction nozzles, these auto mounters can accurately place EDM-machined micrometer-level components onto circuit boards, achieving a placement accuracy of ±0.02 mm and a speed of up to 12,000 components per hour. This forms a collaborative chain of “EDM precision machining + auto mounter high-efficiency assembly”, which is crucial for the mass production of miniaturized devices in consumer electronics and industrial control.

Special Material Machining

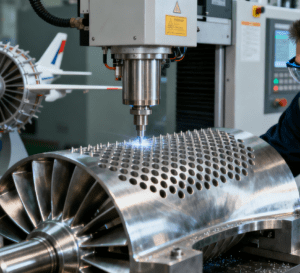

When facing difficult-to-machine materials in the aerospace field — such as superalloys and cemented carbides (which are hard, tough, and prone to wear traditional cutting tools) — EDM transforms into a “tough problem solver”. Relying on electrical energy to overcome hardness with heat, it easily machines cooling film holes in aircraft engine blades, safeguarding the high-temperature performance of aircraft.

Core Advantages: Three “Magics” Redefining Precision Machining

Material Compatibility: Overcoming Hardness with Flexibility

Traditional mechanical machining is like a strongman relying on brute force, using the hardness of cutting tools to shape workpieces. In contrast, EDM is more like a gentle masseur, removing material through thermal energy converted from electrical energy. This characteristic allows it to treat all materials equally: whether it is hardened steel as hard as stone (hardness HRC60+) or aluminum alloy as soft as butter, any conductive material can be precisely machined. It is like a top chef who does not “pick ingredients” — capable of creating exquisite dishes with both steak and tofu.

Shape Freedom: Navigating Complexity with Precision

When a workpiece requires machining in areas inaccessible to conventional tools — such as a slender hole 100 mm deep but only 1 mm in diameter, or a complex cavity with spiral grooves on the inner wall — EDM electrodes act like “shape-shifting wands”. They can be made into any shape according to design requirements, and with the precise movement of the numerical control system, they complete seemingly impossible tasks inside the workpiece. This freedom to machine “anywhere needed” frees designers from the constraints of machining processes, opening the door for the implementation of innovative products.

Micrometer-Level Precision: Guarding Accuracy with Stability

In precision machining, errors are enemies that must be completely eliminated. EDM relies on the high-precision positioning of the numerical control system (with an error of less than 0.001 mm) and the stable control of the discharge process to lock machining accuracy firmly at the micrometer level. What is even more impressive is its ability to use layered discharge and gradual accumulation — similar to piecing together a high-definition image with pixels — to control the contour error of complex curved surfaces within a range invisible to the naked eye. This provides a “millimeter-level commitment” to the reliability of high-end equipment.

The “Smart Brain” Behind the Technology: Tacit Cooperation Between CNC Systems and Pulsed Power Supplies

The magical performance of EDM cannot be achieved without the tacit cooperation of two core components:

CNC System (Computer Numerical Control System): Acting as the “commander” of the machining process, it generates machining paths based on CAD models and controls every tiny movement of the electrode in three-dimensional space — ensuring that the “electric spark partners” move with zero deviation.

Pulsed Power Supply: Serving as the “rhythm master” of energy, it precisely controls the time, energy, and interval of each discharge. This ensures that the electric sparks have enough power to vaporize metal, while avoiding excessive force that could damage the workpiece. This balanced control is the key to achieving high-precision machining.

From cold metal to precision parts, EDM weaves a legend of precision manufacturing through the interweaving of electrical and thermal energy. It is a problem-solver that breaks through material limitations, a “magic wand” that enables design freedom, and a loyal guardian that upholds the bottom line of accuracy. In today’s era where high-end manufacturing competes at the “millimeter level”, this silent “electric spark artist” is using invisible sparks to light up the “craftsmanship glow” of every part. When we marvel at the delicate craftsmanship of precision instruments, we should remember that behind those smooth surfaces lies the persistence and wisdom of countless spark flashes.