In modern industrial production, the importance of surface quality is self-evident. Whether it is power transmission components, laboratory instruments, or medical devices, all have extremely high requirements for surface quality. As an advanced type of digitally controlled mechanical machining, precision CNC grinding plays a crucial role in improving surface quality. As an industry leader, Arie Precision Machinery has garnered significant attention for its precision CNC grinding technology.

Precision CNC grinding is a machining method that uses numerical control technology to control grinding tools for micro-removal of material from the workpiece surface. By precisely controlling parameters such as the movement trajectory, pressure, and speed of the grinding tool, high-precision machining of the workpiece surface can be achieved, thereby enhancing surface quality.

Principles of Precision CNC Grinding for Improving Surface Quality

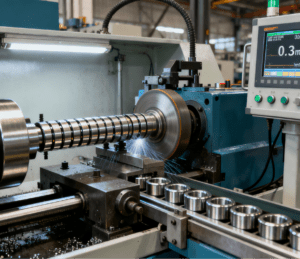

Removal of surface micro-defects

Workpiece surfaces often have micro-defects such as scratches, pits, and protrusions during machining. Precision CNC grinding can remove these micro-defects through the micro-cutting action of the grinding tool, making the surface smoother and flatter. For example, in the manufacturing of power transmission components, surface micro-defects can affect the transmission accuracy and service life of the components. Precision CNC grinding removes surface scratches and protrusions, improving the surface quality of the components, thereby reducing the friction coefficient, increasing transmission efficiency, and extending service life.

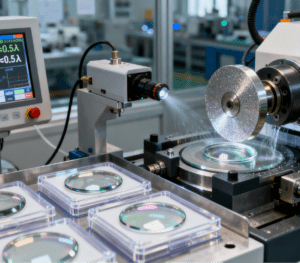

Reduction of surface roughness

Surface roughness is one of the important indicators for measuring surface quality. Precision CNC grinding can minimize the surface roughness of workpieces by controlling the movement trajectory and pressure of the grinding tool. For laboratory instruments and medical devices, reduced surface roughness can improve the accuracy and reliability of the instruments, reduce the likelihood of bacterial growth, and ensure the safety of medical equipment. A typical example is medical catheters—their inner walls and tip parts that directly contact human tissues rely on precision CNC grinding to achieve ultra-low surface roughness, avoiding tissue irritation and reducing bacterial adhesion; subsequently, catheter assembly machines integrate these precisely ground components (such as catheters, connectors, and guide wires) with high precision, ensuring the overall tightness and smoothness of the catheter and further guaranteeing its safety and reliability in clinical applications.

Formation of uniform surface textures

Precision CNC grinding can form uniform surface textures on the workpiece surface according to different requirements. Such surface textures can improve the wear resistance, corrosion resistance, and lubrication performance of the workpiece. For example, in the manufacturing of laboratory instruments, precision CNC grinding can create specific textures on the instrument surface, enhancing its wear and corrosion resistance, enabling it to maintain good performance even in harsh experimental environments.

Key Technologies of Precision CNC Grinding

Numerical control system

The core of precision CNC grinding is the numerical control system. It can precisely control parameters such as the movement trajectory, pressure, and speed of the grinding tool to achieve high-precision machining of the workpiece surface. Arie Precision Machinery’s numerical control system adopts advanced control algorithms and high-precision sensors, enabling real-time monitoring and adjustment of the grinding process to ensure the stability and reliability of machining quality.

Grinding tools

The selection and design of grinding tools have a significant impact on the effect of precision CNC grinding. Different workpiece materials and machining requirements call for different types of grinding tools. For example, for workpiece materials with high hardness, grinding tools with higher hardness are required; for medical devices with extremely high surface quality requirements, grinding tools with special shapes and materials need to be selected to ensure machining effectiveness.

Optimization of machining process parameters

Machining process parameters of precision CNC grinding include grinding pressure, grinding speed, feed rate, etc. Optimizing these parameters can improve machining efficiency and surface quality. Through extensive experiments and data analysis, Arie Precision Machinery can optimize machining process parameters for different workpiece materials and machining requirements to achieve optimal machining results.

As an advanced type of digitally controlled mechanical machining, precision CNC grinding has significant advantages in improving surface quality. Through principles such as removing surface micro-defects, reducing surface roughness, and forming uniform surface textures, as well as key technologies including numerical control systems, grinding tools, and optimization of machining process parameters, precision CNC grinding can play an important role in fields such as power transmission components, laboratory instruments, and medical devices. As a leading enterprise in the industry, Arie Precision Machinery’s precision CNC grinding technology will provide strong support for the development of various industries.

Automation engineering of production lines in the automotive industry

AI production line automation robots in the automotive industry