In the field of modern mechanical processing, the application of digital technology has made precision CNC milling one of the key processes for manufacturing high-accuracy workpieces. With its characteristics of high precision, high efficiency and high flexibility, it plays an important role in numerous industries. Especially for enterprises like Ares Precision Machinery, it is an indispensable processing method in the medical equipment and parts industry (such as dental equipment and supplies, medical devices, etc.)

Core Hardware Foundations: CNC System and Machine Tool Structure

The core of precision CNC milling lies in the advanced CNC system. This system is like the “brain” of the machine tool, accurately directing every machining action. It can precisely control the movement trajectory, speed and feed rate of the milling cutter in three-dimensional space according to pre-written programs.

In the medical equipment and parts industry, the requirements for precision are extremely high. For example, the processing of denture models in dental equipment and supplies requires micron-level dimensional accuracy to ensure the perfect fit of dentures with patients’ oral cavities. Through high-precision interpolation algorithms, the CNC system can achieve extremely smooth motion control, enabling the milling cutter to cut accurately along the predetermined path during processing, thus ensuring the shape accuracy of the workpiece. At the same time, it can also monitor the operating status of the machine tool in real time and compensate for errors in the machining process promptly. For instance, when machining errors caused by factors such as machine tool thermal deformation or tool wear are detected, the CNC system can automatically adjust the tool position or compensate for cutting parameters to ensure the stability of machining accuracy.

To achieve high-precision CNC milling, the structure of the machine tool itself must have high rigidity and high precision. Key components such as the machine tool bed, column and guide rail need to be made of high-quality materials and undergo precision machining and heat treatment processes to ensure good stability and vibration resistance.

Ares Precision Machinery pays attention to details in machine tool manufacturing. It uses high-strength cast iron to make the machine tool bed. This material has good vibration absorption and stability, which can effectively reduce the impact of vibration on precision during processing. The guide rails adopt high-precision linear guide rails or ball screw guide rails to ensure the straightness and positioning accuracy of the worktable during movement. In addition, the spindle of the machine tool is also one of the key components, which needs to have the characteristics of high speed, high stability and high precision. For the processing of medical equipment and parts, high-speed electric spindles are usually adopted, whose rotation speed can reach tens of thousands of revolutions per minute or even higher, and can maintain minimal radial runout and axial movement, providing strong support for high-precision milling. Moreover, to further enhance positioning accuracy and loading/unloading efficiency in batch machining scenarios, Ares Precision Machinery is equipped with a 4 – Axis Robotic Frame Pick – up System for its high-precision CNC milling machines. This system leverages the high flexibility and precise positioning capability of 4-axis movement to realize automatic picking, handling and clamping of machining frames and workpieces. By linking signals with the CNC system, it accurately positions the workpiece into the machining coordinate system, which not only completely avoids positioning errors caused by manual clamping but also significantly shortens auxiliary machining time, perfectly adapting to the continuous processing needs of small-batch and high-precision workpieces in the medical equipment field.

Key Machining Elements: Tool Selection, Management and Process Planning

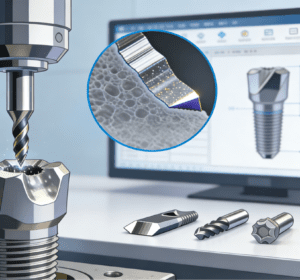

The cutting tool is the part that directly contacts the workpiece in CNC milling, and its quality and performance directly affect the machining accuracy and surface quality. When selecting tools, comprehensive consideration should be given to factors such as workpiece material, shape and processing requirements.

For materials commonly used in the medical equipment and parts industry, such as stainless steel and titanium alloy, tool materials with high hardness and good wear resistance need to be selected. For example, cemented carbide tools are a common choice, which have high cutting efficiency and long service life. Meanwhile, the geometric shape of the tool is also very important; different tool shapes are suitable for different machining processes. For example, when machining curved surfaces, ball-end milling cutters may be selected; while for face milling, flat-end milling cutters are more appropriate.

In addition, tool management is also an important link to ensure machining accuracy. Ares Precision Machinery has established a strict tool management system, covering tool procurement, acceptance, storage, use and maintenance. It regularly inspects and sharpens tools to ensure that the cutting edges of the tools are always sharp and in good condition. At the same time, it adopts an advanced tool condition monitoring system to monitor tool wear in real time, and replaces tools in a timely manner when the wear reaches a certain level, so as to avoid the decline of machining accuracy caused by tool wear.

Reasonable machining process planning is an important guarantee for achieving high-precision CNC milling. Before processing, a comprehensive analysis of the workpiece is required, including its structural characteristics, dimensional accuracy requirements and surface quality requirements, and then a detailed machining process plan is formulated.

Determine a reasonable machining sequence. Generally speaking, rough machining is carried out first to remove most of the machining allowance, followed by semi-finishing and finishing to gradually improve machining accuracy. In rough machining, larger cutting parameters can be adopted to improve machining efficiency; while in finishing, cutting parameters need to be reduced to ensure machining accuracy and surface quality.

Optimize the selection of cutting parameters. The reasonable matching of parameters such as cutting speed, feed rate and depth of cut has an important impact on machining accuracy and efficiency. Through a large number of experiments and practical experience, Ares Precision Machinery has established a complete cutting parameter database, which can quickly and accurately select the optimal cutting parameters according to different workpiece materials and processing requirements.

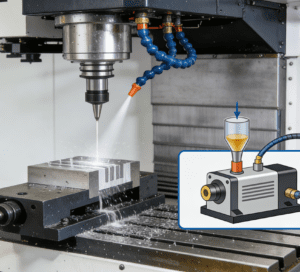

It is also necessary to consider cooling and lubrication during the machining process. Good cooling and lubrication can reduce cutting temperature, reduce tool wear and improve the surface quality of machined parts. In the processing of medical equipment and parts, minimum quantity lubrication (MQL) or dry cutting technology is usually adopted to avoid workpiece contamination by cutting fluid.

Quality Assurance: Real-Time Monitoring and Precision Inspection

In the process of precision CNC milling, strict quality inspection and control are indispensable links. Ares Precision Machinery adopts a variety of advanced testing methods to conduct real-time monitoring of workpieces during processing and inspection of finished products.

During processing, an online measurement system is used to measure the dimensions of the workpiece in real time. Once the dimensional deviation is found to exceed the allowable range, adjustments are made immediately. At the same time, by detecting the roughness of the machined surface, cutting parameters are adjusted in a timely manner to ensure that the surface quality meets the requirements.

For finished workpieces, high-precision measuring equipment such as coordinate measuring machines (CMMs) is used for comprehensive inspection to ensure that various indicators such as dimensional accuracy, shape accuracy and position accuracy of the workpieces meet the design requirements. In addition, appearance inspection is also carried out on the workpieces to ensure that the surface is free of scratches, cracks and other defects.

Through the above series of measures, precision CNC milling can produce high-accuracy workpieces, meeting the strict requirements for precision and quality in the medical equipment and parts industry and other fields. In the process of continuous exploration and innovation, enterprises such as Ares Precision Machinery have continuously improved the level of precision CNC milling technology, making positive contributions to promoting the high-quality development of the manufacturing industry. With the continuous advancement and application of digital technology, it is believed that precision CNC milling will play a greater role in more fields and create more sophisticated workpieces.