In modern manufacturing, CNC machining centers are widely used for processing various parts due to their high precision, high efficiency, and high level of automation. CNC machining centers can be categorized into 3-axis, 4-axis, and 5-axis types based on the number of motion axes. This article will elaborate on the characteristics and application fields of 3-axis, 4-axis, and 5-axis CNC machining centers to help readers better understand the differences between them.

3-Axis CNC Machining Centers: Foundation and Efficiency

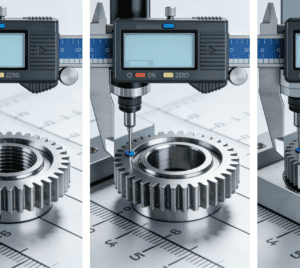

A 3-axis CNC machining center is the most traditional type of machining center, consisting of three linear motion axes: X, Y, and Z. It is suitable for most conventional milling, drilling, and cutting operations. 3-axis machines excel at processing flat parts and simple 3D components, but they may be limited when dealing with complex curved surfaces. For standard cylindrical springs or flat spiral springs produced by Automatic Spring Equipment, 3-axis machining centers can efficiently complete the machining of basic forming molds and fixing fixtures, leveraging their cost-effectiveness and high efficiency to meet mass production needs.

4-Axis CNC Machining Centers: Added Flexibility

A 4-axis CNC machining center adds one rotary axis (usually the A-axis or B-axis) to the 3-axis configuration. This allows the machine to rotate the workpiece during the machining process, enabling the fabrication of more complex geometric shapes. 4-axis machines are suitable for processing parts with bevels or specific angular requirements. When manufacturing precision torsion springs or conical springs—core products of Automatic Spring Equipment—4-axis machining centers utilize their rotary axis to process mold cavities with inclined grooves or spiral angles in a single clamping, ensuring consistent spring pitch and angle precision, which is difficult to achieve with 3-axis equipment.

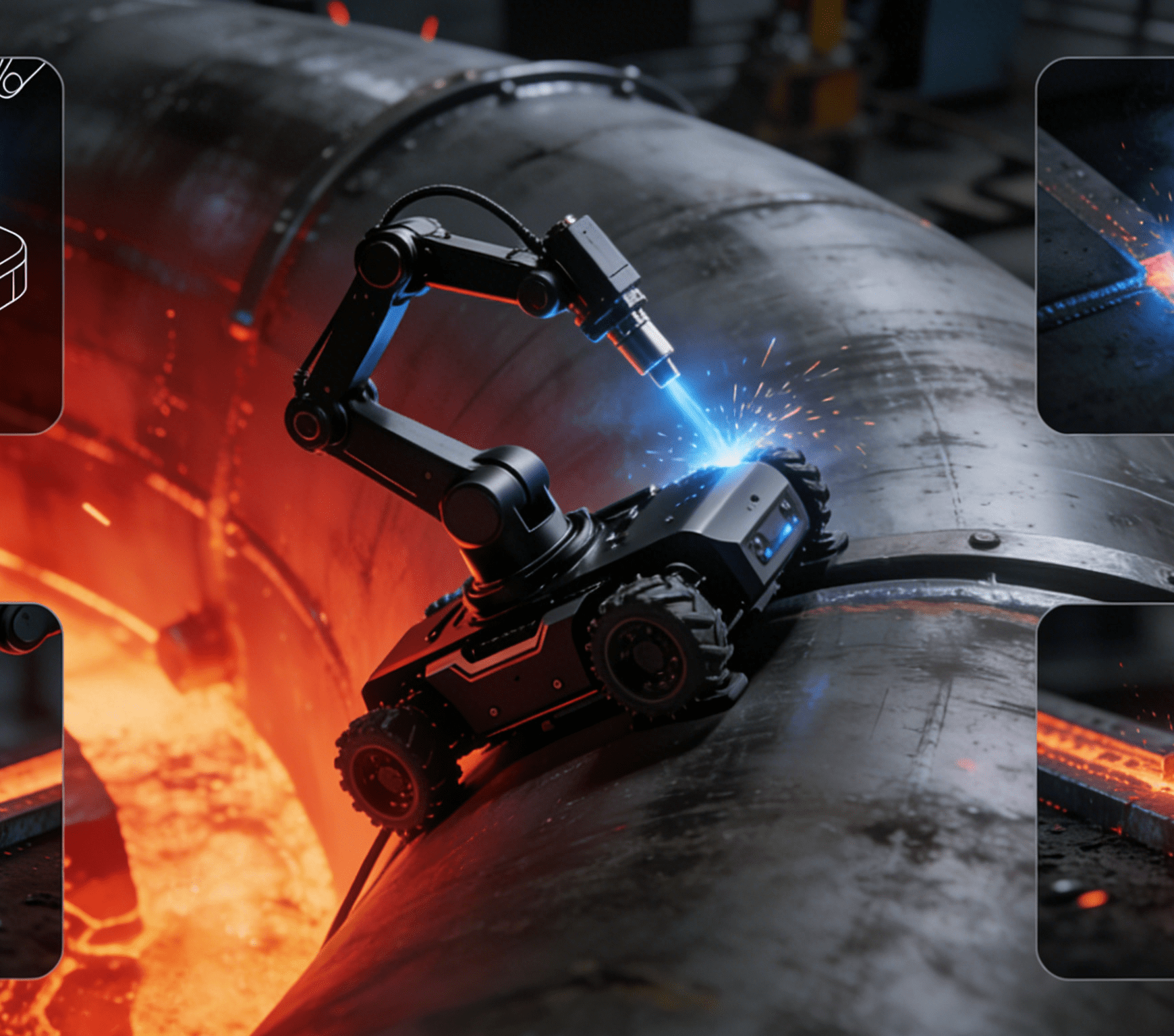

5-Axis CNC Machining Centers: The Solution for Complex Machining

A 5-axis CNC machining center comprises three linear axes (X, Y, Z) and two rotary axes (any two of A, B, or C axes). This configuration offers extremely high machining flexibility, allowing machining at nearly any angle in a single clamping setup. 5-axis machines are particularly suited for processing complex spatial surfaces, molds, and aerospace components. For high-end custom Automatic Spring Equipment used in aerospace or medical fields, which requires machining of complex spatial curved springs (such as variable-pitch spiral springs or 3D shaped springs), 5-axis machining centers can achieve full-dimensional precision machining of core molds and forming components, ensuring the spring’s spatial structure accuracy and fatigue resistance.

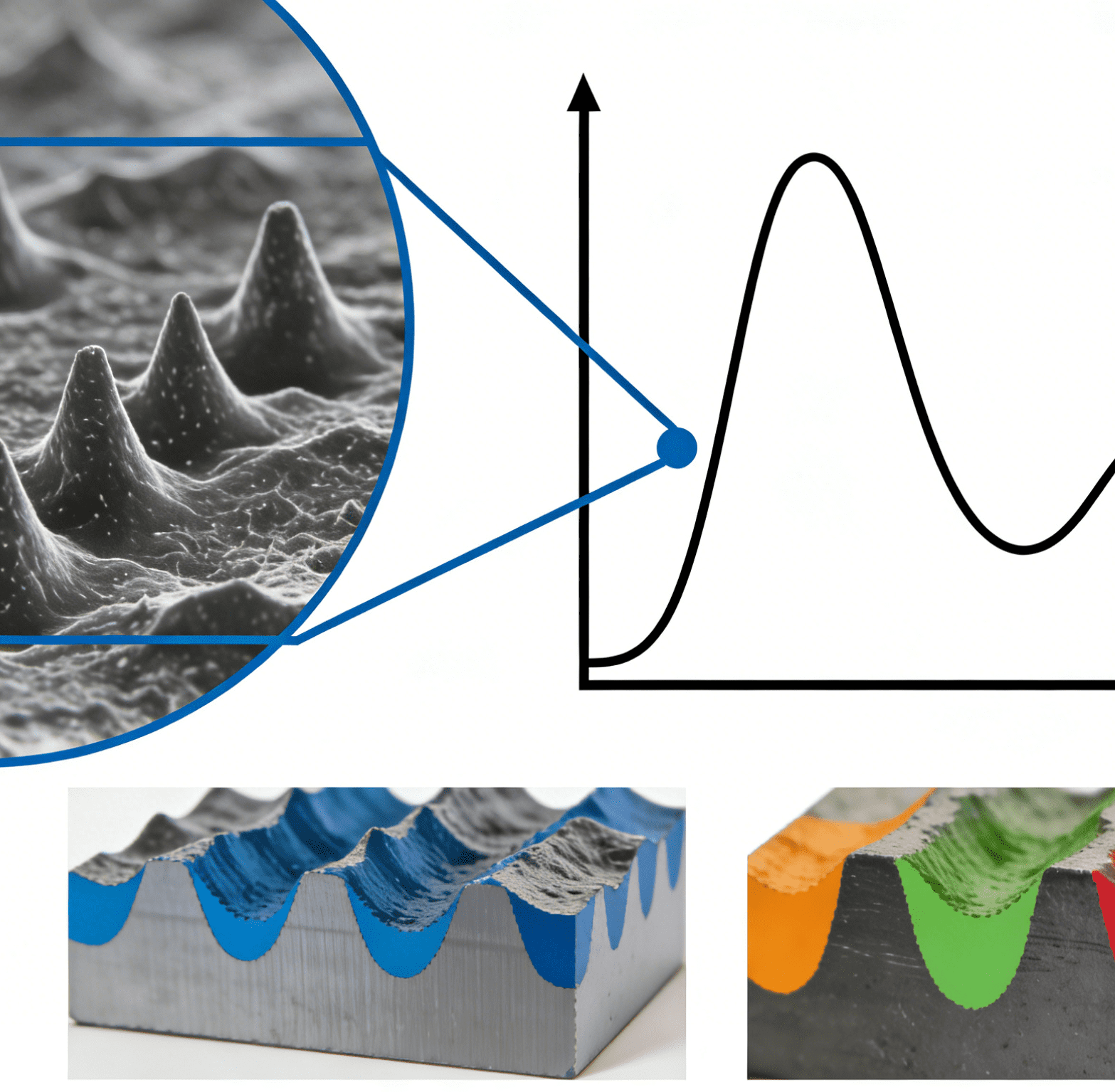

Technical and Application Differences

Machining Precision: As the number of axes increases, the machining precision and repeatability of the machine tool improve accordingly.Machining Efficiency: Multi-axis machines can complete machining with fewer clamping operations, thus boosting production efficiency.Complexity: 3-axis machines are suitable for simple parts, while 4-axis and 5-axis machines are designed for processing complex components.Cost: The more axes a machine has, the higher its purchase and maintenance costs will be.

- axis, 4-axis, and 5-axis CNC machining centers each have unique advantages and applicable fields. 3-axis CNC machining centers are ideal for processing relatively simple parts, featuring low cost and easy operation. 4-axis CNC machining centers add one rotary axis to the 3-axis design, enabling multi-axis machining and making them suitable for complex parts. 5-axis CNC machining centers support five-axis movement, allowing full-dimensional machining and catering to high-complexity, high-precision parts. ARES Precision should select the appropriate CNC machining center based on specific machining requirements, part complexity, and cost considerations.

How to choose a multi-component capping assembly machine suitable for your production line?