In today’s rapidly developing medical industry, from minimally invasive surgical instruments to implantable medical devices, the performance of every core component is directly related to patients’ life safety and treatment outcomes. The foundation of all this relies on the high-standard machining of precision medical parts. Compared with ordinary industrial precision parts, precision medical parts not only need to meet strict dimensional tolerances but also take into account special requirements such as biocompatibility and corrosion resistance stability. This makes “precision machining” no longer a mere technical indicator, but a core link that bears medical responsibilities.

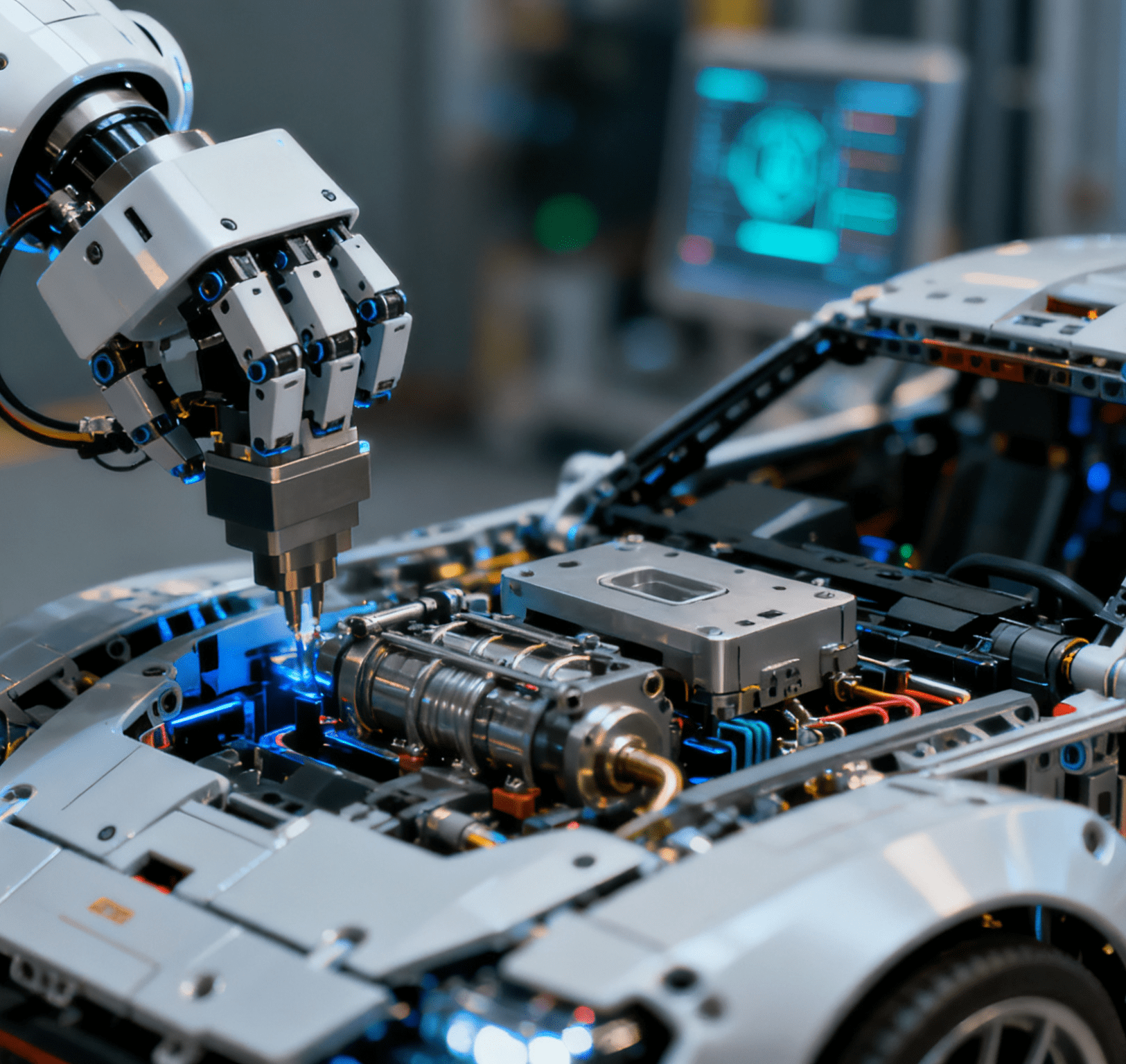

Taking the end effector parts of surgical robots as an example, their motion precision directly determines the accuracy of surgical incisions, and slight errors may cause irreversible harm to patients. This characteristic means that the machining of precision medical parts must comply with higher precision standards from the very beginning.

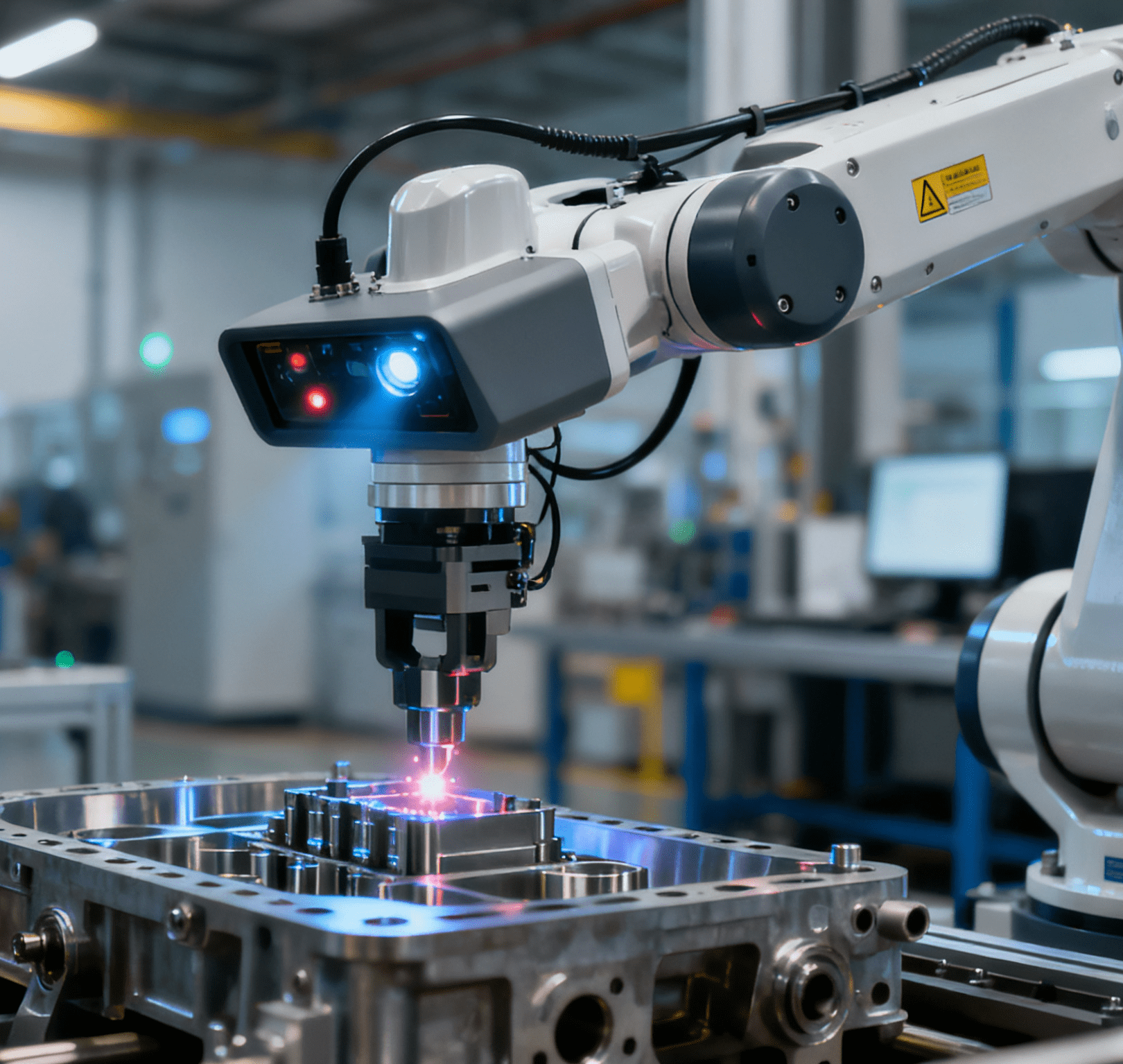

Notably, in the assembly process of precision medical equipment components that require stable fastening—such as the connection parts of surgical instrument handles or the fixed structures of medical imaging device brackets—the Automatic Nut Bolt Washer Assembly Machine has become a key guarantee for precision and consistency. This equipment integrates visual positioning, torque control and automatic feeding systems, which can complete the sequential assembly of nuts, bolts and washers with micron-level positioning accuracy. It not only avoids the fastening torque inconsistency and assembly deviation caused by manual operation but also realizes real-time recording of assembly parameters (such as torque value, tightening angle) and uploads them to the quality traceability system. For example, in the assembly of minimally invasive surgical forceps joints, the machine controls the bolt tightening torque within ±0.05 N·m, ensuring the smooth rotation of the forceps while preventing loosening risks during surgery, perfectly matching the high-precision and high-reliability requirements of medical precision machining.

Beyond Micron-Level: The Unique Precision Requirements of Medical Parts

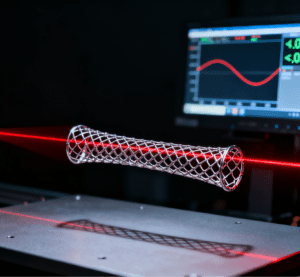

The precision requirements for precision medical parts have exceeded the traditional industrial understanding of “micron-level” and entered a more refined precision field, showing the characteristic of “multi-dimensional synchronous precision”. Taking the electrode array parts of cochlear implants as an example, each electrode contact must meet extremely high dimensional tolerance standards, the contact spacing error must be controlled within an extremely low range, and the surface roughness of the electrodes must reach an ultra-fine level. Only by meeting these indicators can the accurate connection between the electrodes and the auditory nerve be ensured, and the impact of signal transmission deviations on hearing recovery effects be avoided.

In addition, implantable parts such as cardiovascular stents have extremely thin tube walls. During the machining process, it is necessary to ensure that the tube walls are uniform without deviations, and at the same time, ensure that the angle error of each support unit after the stent is expanded is within a very small range. This dual precision challenge of “thin-walled + complex structure” is a prominent feature that distinguishes medical precision machining from other fields.

The Three-In-One System: Technology, Process and Inspection

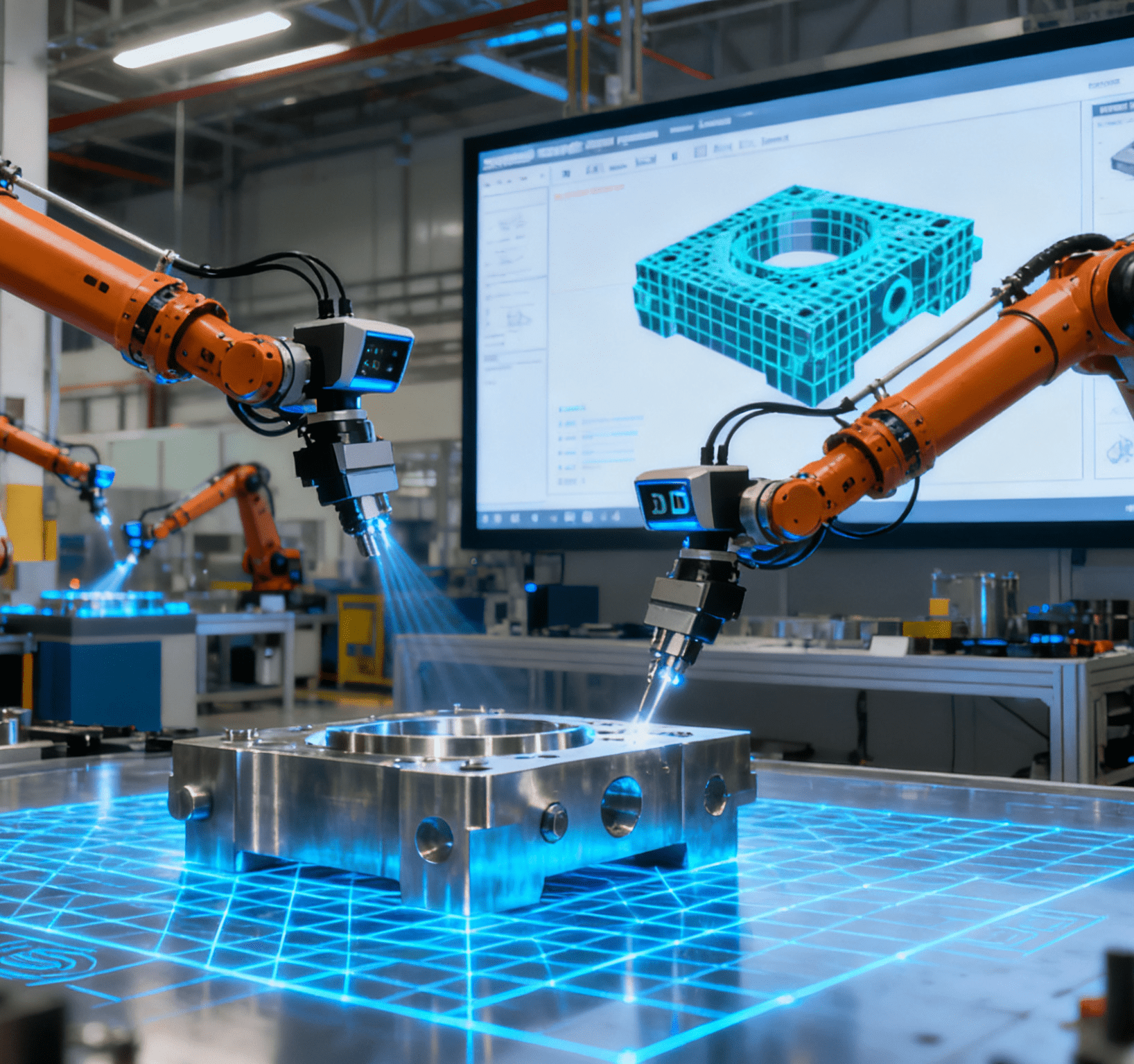

To meet the ultimate precision requirements of precision medical parts, it is not enough to rely solely on high-end equipment; it is more necessary to build a three-in-one precision machining system integrating “technology + process + inspection”.

At the level of machining equipment, it is necessary to introduce 5-axis linkage machining centers and ultra-precision grinding machines. Among them, 5-axis equipment has extremely high repeat positioning accuracy and can accurately process complex curved surfaces and special-shaped structures of medical parts. For example, for the arc guide rail parts in the orthopedic surgical navigation and positioning module, 5-axis synchronous machining can complete the milling and polishing of the guide rail curved surface in one go, avoiding the accumulation of errors caused by multiple clamping operations.

At the same time, in view of the machining characteristics of special materials such as medical titanium alloy and PEEK, it is necessary to develop exclusive cutting parameters and cooling processes. For instance, when machining titanium alloy parts, low-temperature oil mist cooling technology is adopted, which can not only reduce the precision deviation caused by material thermal deformation but also avoid the impact of cutting fluid residues on biocompatibility, achieving dual guarantees of precision and material performance.

Real-Time Monitoring & Full-Process Traceability: The Precision Guarantee Line

“Real-time monitoring + full-process traceability” is the core system to ensure the stable precision of precision medical parts. During the machining process, online laser diameter gauges and coordinate measuring machines (CMMs) must be equipped. Laser diameter gauges can perform high-frequency real-time detection of key dimensions of parts; once a deviation exceeding the preset threshold is found, the equipment will automatically pause and adjust parameters. CMMs, on the other hand, need to conduct comprehensive precision review of the machined parts, covering dimensional tolerances, geometric errors, and surface roughness, and all data must be entered into an exclusive quality traceability system.

In addition, it is necessary to establish a constant temperature and humidity medical machining workshop to strictly control the ambient temperature and humidity. Changes in temperature can cause linear expansion of titanium alloy materials, which in turn affects the dimensional precision of parts. This precise control of environmental variables is a strict requirement for precision control in the field of medical precision machining.

With the continuous advancement of precision medicine and personalized medicine, the precision requirements for precision medical parts are constantly escalating, driving continuous innovation and breakthroughs in the field of precision machining. Currently, the industry not only needs to provide standardized precision medical part machining services but also needs to offer “customized precision solutions” based on the R&D needs of different medical devices. For example, in the R&D of tumor proton therapy equipment, it is necessary to optimize the machining process through joint research, controlling the aperture tolerance of beam control parts within an extremely high precision range, to help the equipment achieve precise “targeted strike” on tumor cells and reduce damage to normal tissues.

In the future, the field of medical precision machining should adhere to the development concept of “unlimited precision, boundless responsibility”, continue to deepen technological innovation, and empower the development of the medical industry with more exquisite craftsmanship and more stable quality, so as to safeguard life and health.

Robots realize the automated assembly of automotive connectors