Technological Breakthrough

Dalian Rubber & Plastics Co., Ltd., a subsidiary of Dalian Heavy Industry Equipment Group, has developed four sets of new synthetic resin extrusion granulation units for a domestic petrochemical enterprise. As a core project this year, these units boast extremely high technological standards and market value. To meet the performance requirements of the units and effectively produce qualified special resin particles, the units adopt ultra-long, ultra-thin mandrels with an ultra-large length-to-diameter ratio. High-precision machining of such special mandrels has long been recognized as a major challenge in the industry, posing significant difficulties for Dalian Rubber & Plastics.

Core Challenges: Ultra-Large Aspect Ratio and Incoming Material Warpage

In addition to the mandrel’s inherent ultra-large length-to-diameter ratio, factors such as material warpage of incoming workpieces also exert a great impact on machining. These issues lead to core pain points including large mandrel deflection, poor rigidity, and easy warpage, which have long restricted high-precision processing in the industry.

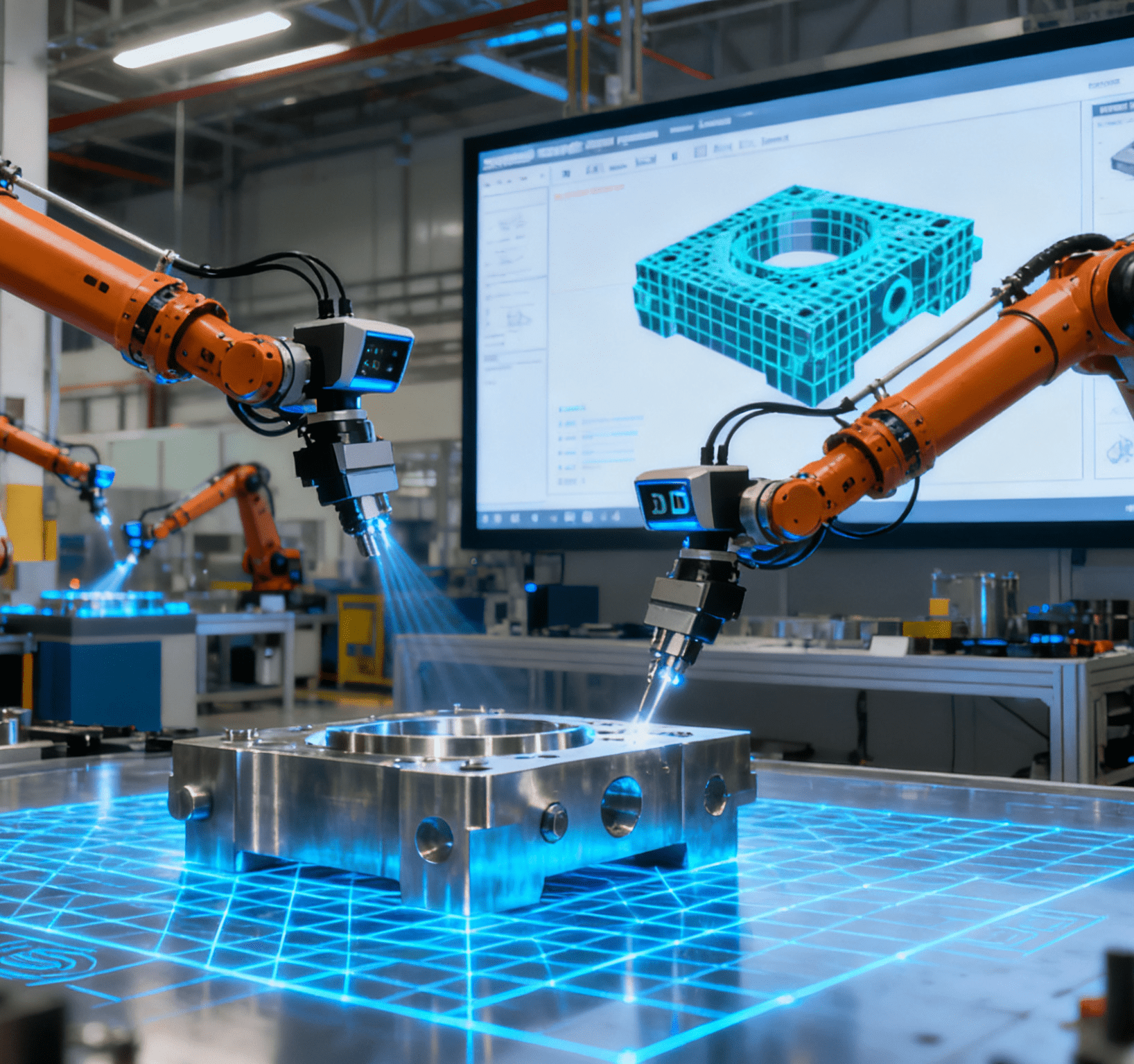

Systematic Breakthrough: 15 Key Measures Covering the Entire Machining Chain

To address these constraints, Dalian Rubber & Plastics established a research team based on its “Skill Committee”, focusing on three key processes: turning, grinding, and hobbing. Leveraging advanced equipment such as intelligent straightening machines, 15-meter CNC grinding machines, and 15-meter CNC hobbing machines, the team formulated and implemented 15 technological measures. Seven measures target lathe machining and seven focus on grinding (covering support tooling optimization, warpage control, intelligent compensation, and datum transfer), with one additional measure for standard storage specifications. The team also adopted self-developed auxiliary tooling, program compensation, optimized tool/abrasive selection, and refined cutting parameter adjustment, while implementing the “previous process serving the next process” concept for efficient process connection.

Dual Gains in Efficiency & Quality: Technological Leap and Industry Advantages

Finally, the team successfully overcame multiple technical bottlenecks, increasing the mandrel’s overall machining efficiency by more than 40% and achieving dual improvements in efficiency and quality. All 15 achievements have been put into application, with two key technologies to be patented. This breakthrough ensures the on-schedule and high-quality delivery of key projects, enhances the company’s core competitiveness in high-end equipment manufacturing, accumulates valuable experience for complex part machining, and consolidates its industry-leading technological advantages.