Industrial automation powers modern manufacturing, from massive stamping presses to precision small-scale machines. While automated equipment is designed for self-sufficiency, human interaction remains critical—for setup, monitoring, troubleshooting, and initiation. For decades, physical buttons, electromechanical dials, and manual controls handled this human-machine interface (HMI). Today, however, touchscreen HMIs—with their versatile input/output capabilities—have revolutionized how production facilities, original equipment manufacturers (OEMs), and systems integrators (SIs) interact with custom automated assembly machinery, unlocking new levels of efficiency and flexibility.

The Evolution of HMIs in Custom Automated Assembly Machinery

In custom automated assembly systems, the HMI is the bridge between operator and machine. Traditional physical controls worked for basic tasks but lacked adaptability: reconfiguring a dial for a new product line or adding a new monitoring metric required hardware changes, slowing down customization.

Touchscreen HMIs have transformed this. For custom automated assembly machinery—built to handle unique parts, workflows, or industry-specific requirements—touchscreens offer:

Real-time customization: Operators can adjust parameters (e.g., assembly speed, torque limits) or switch between product profiles with a few taps, critical for low-volume, high-mix production.

Integrated data visibility: Live dashboards display key metrics (error rates, cycle times, maintenance alerts) directly on the screen, enabling faster decision-making.

Simplified training: Intuitive interfaces reduce onboarding time for operators, even as machinery complexity grows.

This shift isn’t just about convenience—it’s about making custom automated assembly machinery more agile, a must in today’s fast-changing manufacturing landscape.

PMi2: Expertise in Custom Automated Assembly Machinery & Turnkey Automation

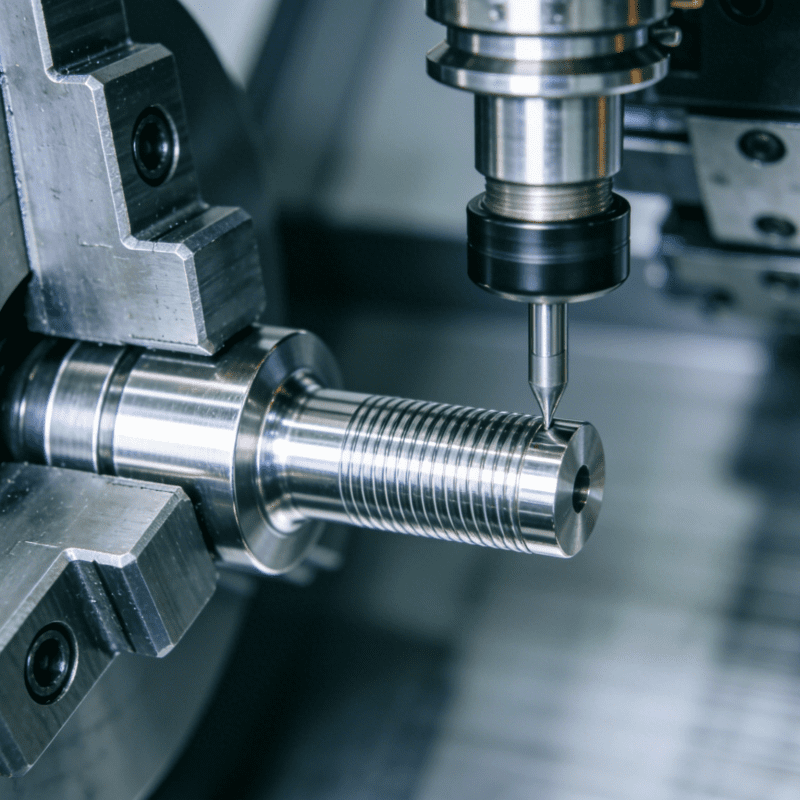

With over 30 years in industrial automation—first as an engineer at a major automotive supplier, now as owner of PMi2 (Seneca, S.C.)—I’ve seen firsthand how custom automated assembly machinery drives manufacturing success. PMi2 stands out for its dual focus: half our business delivers precision production machining, while the other half specializes in building custom automated equipment and integrating turnkey automation solutions for clients worldwide.

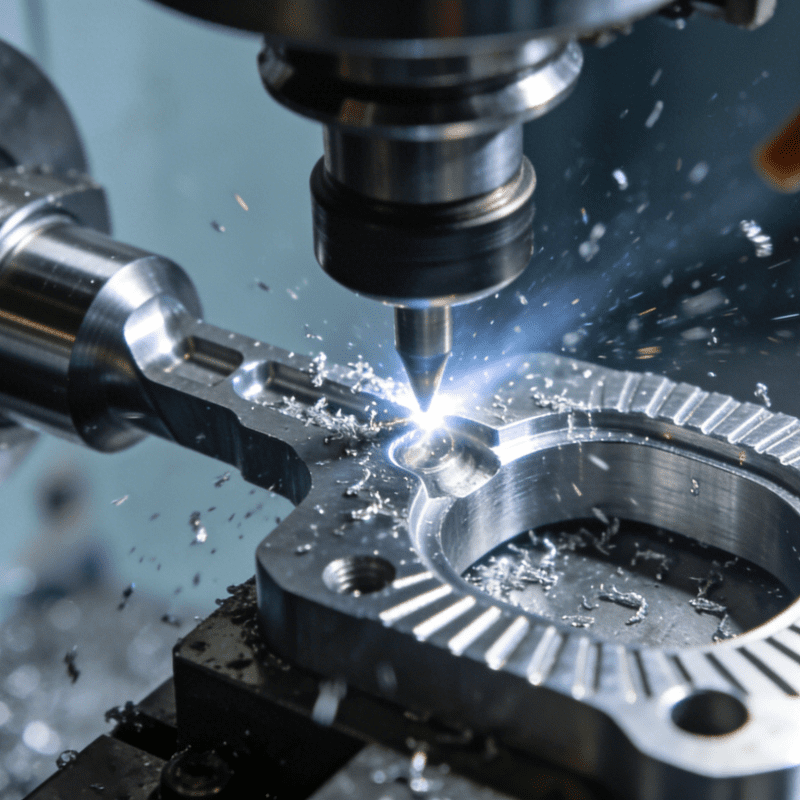

This synergy—combining machining expertise with automation design—lets us tackle unique challenges. We follow an ISO 9000-registered process for every stage, from design to manufacturing, ensuring consistency and quality. Our custom automated assembly machinery portfolio includes:

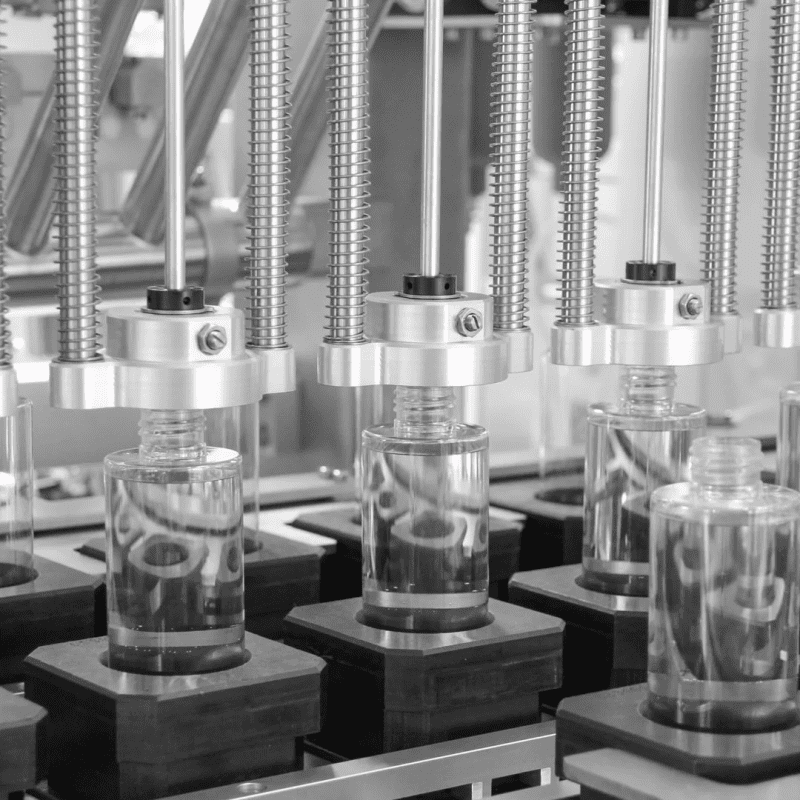

Specialized production machines: Tailored for discrete parts assembly, from automotive components to medical device parts.

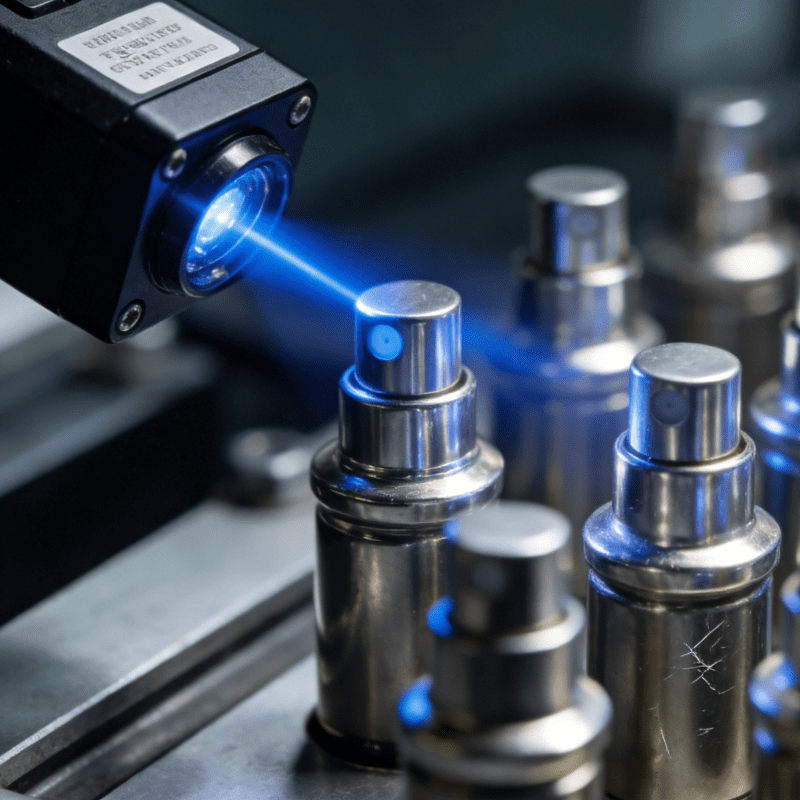

Testing & inspection systems: Integrated with vision sensors and AI to verify part quality in real time during assembly.

Robotics & material handling: Automated feeding, tending, and transfer systems optimized for specific part geometries and production volumes. A standout example is our 4-Axis Robotic Tray Loading System, engineered to handle diverse part sizes—from small electronic components to larger medical devices—with unparalleled flexibility. Equipped with a touchscreen HMI, operators can quickly reprogram tray layouts, adjust loading speeds, or switch between product types (e.g., from battery cells to surgical tools) in minutes. The 4-axis design enables precise positioning even with irregularly shaped parts, while integrated sensors confirm proper loading alignment—critical for avoiding jams in downstream assembly or packaging.

Serving Diverse Industries with Custom Solutions

Custom automated assembly machinery isn’t one-size-fits-all—and neither are our solutions. PMi2’s systems support a wide range of sectors:

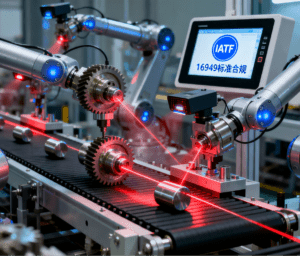

Automotive: Assembly lines for transmission components, sensors, and electrical connectors, built to meet IATF 16949 standards.

Energy: Automated machinery for battery cell assembly and renewable energy component production, focused on precision and safety.

Electronics & Batteries: High-speed assembly systems for micro-components, with touchscreen HMIs to adjust for tight tolerances.

Pharmaceutical & Medical: Cleanroom-compatible automated assembly and inspection systems, designed to comply with FDA and ISO 13485 regulations—including our 4-Axis Robotic Tray Loading System, which minimizes human contact in sterile environments.

Why Custom Automated Assembly Machinery Matters

In a world where manufacturing demands are increasingly specialized—whether for unique part designs, strict regulatory requirements, or low-volume production—off-the-shelf equipment falls short. Custom automated assembly machinery, paired with modern touchscreen HMIs, delivers:

Efficiency: Systems built to match your exact workflow, reducing waste and cycle times.

Flexibility: Easy reconfiguration for new products, keeping your facility adaptable.

Quality: Integrated testing and data tracking ensure consistent output, reducing defects.

At PMi2, we don’t just build machines—we design custom automated assembly solutions that grow with your business. From concept to deployment, our dual expertise in machining and automation ensures your system—whether a specialized assembly line or a 4-Axis Robotic Tray Loading System—is precise, reliable, and ready to tackle tomorrow’s manufacturing challenges.

Contact us today to explore how custom automated assembly machinery can transform your production line.

Artificial Intelligence Five-sided Automatic Assembly Machine

Optimization of the five-sided automatic assembly machine by AI