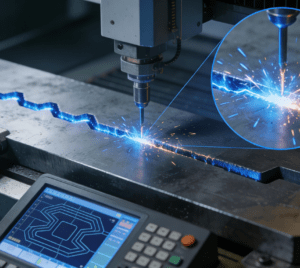

CNC Wire Cut EDM TechnologyCNC wire cut Electrical Discharge Machining (EDM) technology uses a continuously moving thin metal wire (referred to as the electrode wire) as the tool electrode. It removes metal from the workpiece through pulsed electrical discharge, thereby achieving cutting and machining of the workpiece.During the machining process, a certain discharge gap is always maintained between the electrode wire and the workpiece. When the pulse voltage generated by the pulse power supply is applied between the electrode wire and the workpiece, spark discharge occurs in an extremely short time. This causes the local metal on the workpiece surface to melt and vaporize instantly and be eroded away. By controlling the movement trajectory of the electrode wire through the CNC system, workpieces of various complex shapes can be cut with high precision.Classification of CNC Wire Cut EDM Technology

High-Speed Wire Cut EDM

High-speed wire cut EDM is an original wire cut machining technology developed in China. The electrode wire usually adopts molybdenum wire, which moves back and forth at a relatively high speed (generally 8–10 m/s).

The advantages of high-speed wire cut EDM are high machining efficiency and low cost, making it suitable for machining workpieces with relatively low precision requirements. However, its machining accuracy and surface quality are relatively low, so it is generally applied in the manufacturing of medium and low-precision molds and parts processing.

Low-Speed Wire Cut EDM

The electrode wire used in low-speed wire cut EDM is usually copper wire or brass wire, which moves unidirectionally at a relatively low speed (generally 0.2–0.5 m/s).

Low-speed wire cut EDM has the advantages of high machining accuracy and excellent surface quality, and can achieve nanometer-level machining precision. Nevertheless, its machining efficiency is relatively low and the cost is high. It is suitable for machining workpieces with extremely high precision requirements, such as precision components in the aerospace field and micro-parts in the electronics and electrical appliance industry.

Characteristics of CNC Wire Cut EDM Technology

High Precision

CNC wire cut EDM technology enables high-precision machining. Especially low-speed wire cut EDM, which can achieve nanometer-level machining accuracy. This gives it a unique advantage in manufacturing high-precision molds and precision parts.

Since the diameter of the electrode wire is very small, usually ranging from 0.05 to 0.3 mm, it can cut extremely fine gaps and complex shapes, meeting the needs of various high-precision machining tasks.

Strong Capability in Machining Complex Shapes

CNC wire cut EDM technology can machine workpieces of various complex shapes by controlling the movement trajectory of the electrode wire through the CNC system. Whether it is 2D planar graphics or 3D solid shapes, they can be cut and machined easily.

For workpieces with complex structures such as sharp corners, narrow slots, and deep grooves, CNC wire cut EDM technology also demonstrates excellent machining capability, which is difficult to achieve with other machining methods.

No Need for Special Tools

Different from traditional mechanical machining methods, CNC wire cut EDM technology does not require the use of special tools. The electrode wire can be replaced according to machining needs, and the cost is relatively low.

This makes CNC wire cut EDM technology well-adapted to machining materials of various hardness levels. It can effectively process both high-hardness materials such as cemented carbide and quenched steel, and soft materials such as aluminum alloy and copper alloy.

Environmentally Friendly Machining Process

The CNC wire cut EDM machining process generates no cutting force, and produces no cutting waste or noise pollution. Meanwhile, as water-based working fluid is used for cooling and chip removal, the machining process is relatively environmentally friendly.

This has enabled CNC wire cut EDM technology to be widely used in occasions with high environmental requirements, such as the manufacturing of electronics, electrical appliances and medical devices.

Application Fields of CNC Wire Cut EDM Technology

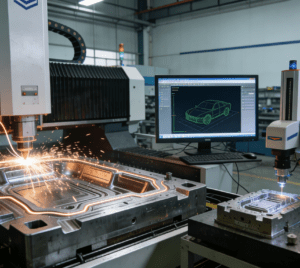

Mold Manufacturing

CNC wire cut EDM technology plays an important role in mold manufacturing. It can be used to produce various stamping molds, injection molds, die-casting molds, etc. Through precise machining, it can ensure the dimensional accuracy and surface quality of the molds, and improve the service life and production efficiency of the molds.

For example, in automotive mold manufacturing, CNC wire cut EDM technology can machine complex automotive panel molds, and many manufacturers further adopt the Universal Assembly System to match the high-precision mold components—this system uses standardized positioning modules and adaptive clamping mechanisms to quickly assemble the wire-cut precision parts, avoiding assembly errors caused by manual operation, and realizing efficient connection between high-precision machining and assembly, providing stronger support for the development of the automotive industry.

Aerospace Field

In the aerospace field, the requirements for the precision and quality of parts are extremely high. CNC wire cut EDM technology can machine various high-precision aerospace parts, such as aircraft engine blades and spacecraft structural components.

These parts usually have complex shapes and strict dimensional accuracy requirements, and CNC wire cut EDM technology can meet these requirements, making contributions to the development of the aerospace industry.

Electronics and Electrical Appliance Industry

Many parts in the electronics and electrical appliance industry are characterized by miniaturization and precision. CNC wire cut EDM technology can machine various micro-parts, such as mobile phone chips and electronic connectors.

At the same time, CNC wire cut EDM technology can also be used in the manufacturing of Printed Circuit Boards (PCBs), providing important technical support for the development of the electronics and electrical appliance industry.

Medical Device Manufacturing

Medical device manufacturing has very high requirements for the precision and hygiene of parts. CNC wire cut EDM technology can machine various high-precision medical device parts, such as artificial joints and dental instruments.

Due to the environmentally friendly machining process that does not cause pollution to the parts, CNC wire cut EDM technology has been widely applied in the field of medical device manufacturing.