In the modern metal manufacturing sector, CNC (Computer Numerical Control) spinning has emerged as one of the key processes bridging material properties and the demands of precision manufacturing, thanks to its high-efficiency shaping capability for rotationally symmetric workpieces. Based on traditional spinning technology, it achieves automated control through a CNC system. This not only preserves the mechanical properties of metal materials but also meets the diverse requirements of different industries regarding workpiece precision, cost, and mass production. Currently, it is widely applied in various core manufacturing fields such as automotive, aerospace, and new energy.

Technical Principles and Core Characteristics of CNC Spinning

CNC spinning is essentially a metal plastic deformation process. Its core workflow revolves around two key actions: “rotation” and “feed”, and standardized production is achieved through the precise control of the CNC system.

Technical Principles

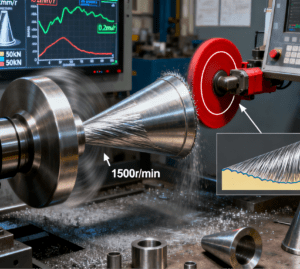

A metal sheet or prefabricated blank is fixed on the spindle of a CNC spinning machine, which drives the blank to rotate at high speed. Meanwhile, the CNC system controls the spinning wheel (a forming tool) to feed towards the blank along a preset path. By continuously applying pressure, the metal material gradually conforms to the contour of the mold, eventually forming a workpiece with a rotationally symmetric structure, such as cylindrical, conical, or curved generatrix shapes.

Core Characteristics

Different from traditional manual spinning, the core advantages of CNC spinning lie in “controllability” and “consistency”. The CNC system can precisely set parameters such as spindle speed, spinning wheel feed rate, and pressure, ensuring that the dimensional error of workpieces in the same batch is controlled within the range of ±0.01mm. Additionally, processing parameters can be stored and reused, significantly reducing the cost of production changeovers and meeting both small-batch customization and large-batch production needs.

Core Application Fields and Typical Workpieces of CNC Spinning

The core applicable scenario of CNC spinning is “rotationally symmetric metal workpieces”, and its applications cover the entire range from precision components to large structural parts. The main fields and typical products are as follows:

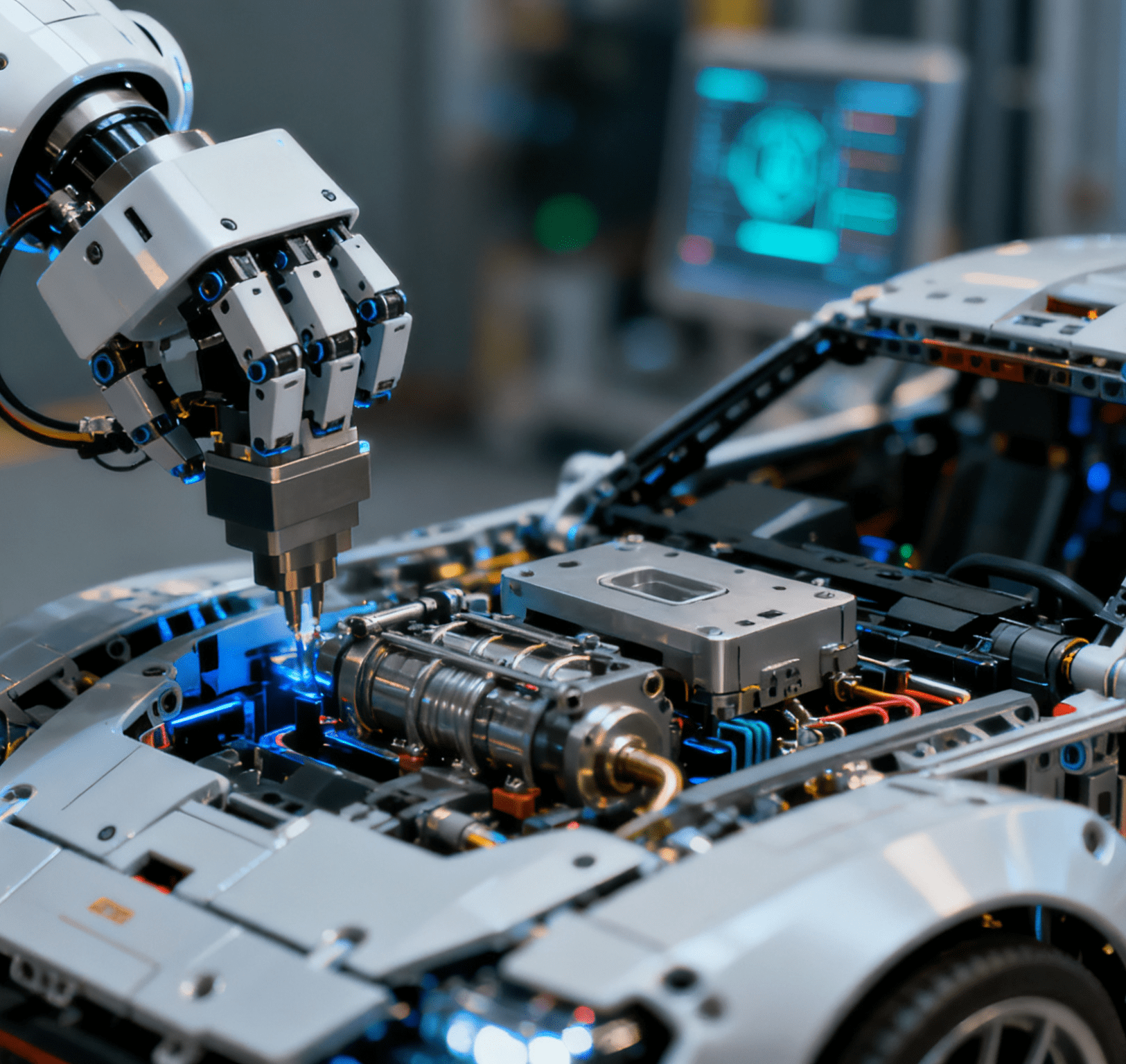

Automotive Industry: It is mainly used for power system and body structural parts, such as turbocharger housings, exhaust system bellows, fuel tank end caps, and steering wheel skeletons. These workpieces need to balance light weight and high strength. CNC spinning can achieve a material utilization rate of over 95%, which is superior to traditional cutting processes.

Aerospace Field: It is suitable for components requiring high precision and high reliability, such as aircraft engine ducts, hemispherical heads of fuel tanks, and satellite antenna reflectors (mostly made of aluminum alloy or titanium alloy via spinning). The processing process has no weld seams, which can avoid stress concentration and improve the fatigue resistance of the workpiece.

New Energy Field: The application is concentrated in energy storage and power generation equipment, such as lithium battery casings (cylindrical and prismatic), hydrogen storage cylinder heads, and wind turbine hub connecting sleeves. Among them, the spinning forming of lithium battery casings can reduce wall thickness deviation and improve battery energy density and safety.

Civil and Industrial Hardware: It covers components for daily use and general equipment, such as kitchen utensils (stainless steel pot liners), lamp housings, pressure vessel heads, and motor end caps. Most of these workpieces are small to medium-sized. CNC spinning enables quick mold change, meeting the production needs of multiple varieties and short cycles. Notably, in the production of hardware fasteners and assembly parts, CNC spinning is often integrated with Automatic Buckle Feeding And Assembly systems—realizing continuous automatic feeding, precise positioning, and one-stop forming-assembly of buckle components, which further enhances production efficiency and assembly consistency for small-batch, multi-variety hardware products.

Comparative Advantages of CNC Spinning Compared with Mainstream Metal Forming Processes

In the field of metal forming, stamping, casting, and cutting are common processes. CNC spinning exhibits significant advantages in specific scenarios, with comparisons made from the following dimensions:

Material Utilization Rate: The material utilization rate of CNC spinning can reach 90%-98%, generating minimal waste. Stamping processing requires blanking, so its utilization rate is mostly 60%-80% with relatively more waste. Casting processing needs to cut off risers, resulting in a utilization rate of approximately 70%-85%. Traditional cutting processing produces a large amount of chips, with a utilization rate of only 50%-70%, leading to obvious material waste.

Workpiece Precision: The dimensional error of CNC spinning can be controlled within ±0.01mm, and the surface roughness can reach Ra1.6. The dimensional error of stamping processing depends on mold precision, mostly around ±0.1mm. Casting processing has a larger dimensional error, approximately ±0.5mm, and usually requires subsequent secondary processing. Although traditional cutting processing can achieve high precision of ±0.005mm, its processing efficiency is low, making it difficult to adapt to mass production.

Mechanical Properties: During the CNC spinning process, metal fibers remain continuous, and the workpiece strength can be increased by 15%-30%. Stamping processing tends to cause local stress concentration in the workpiece, which needs to be eliminated through annealing. Cast workpieces are prone to internal pores, resulting in low density and insufficient stability of mechanical properties. Traditional cutting processing cuts off metal fibers, which instead slightly reduces the workpiece strength.

Cost Adaptability: CNC spinning has obvious cost advantages in small to medium-batch production (starting from 100 pieces) without the need for high mold investment. Stamping processing is more suitable for large-batch production (starting from 10,000 pieces), but the cost of a single set of molds can range from tens of thousands to hundreds of thousands of yuan, leading to poor economy in small-batch production. Casting processing has better cost control for large and complex structural parts. Traditional cutting processing is suitable for single-piece customization; however, in mass production, its cost increases significantly due to low efficiency and high material waste.

Applicable Workpiece Types: CNC spinning focuses on rotationally symmetric workpieces, such as cylindrical, conical, and curved surface structures. Stamping processing is good at flat or simple curved surface workpieces. Casting processing can produce complex special-shaped structural parts. Traditional cutting processing is more suitable for asymmetric high-precision components.

Comprehensively, the core competitiveness of CNC spinning lies in the “balance between precision and cost”: it not only avoids the high mold investment of stamping processing but also solves the precision defects of cast workpieces and the material waste problem of cutting processing. It is particularly suitable for the production of metal workpieces with “rotational symmetry, medium to high precision, and small to medium batches”.

Technical Development Trends of CNC Spinning

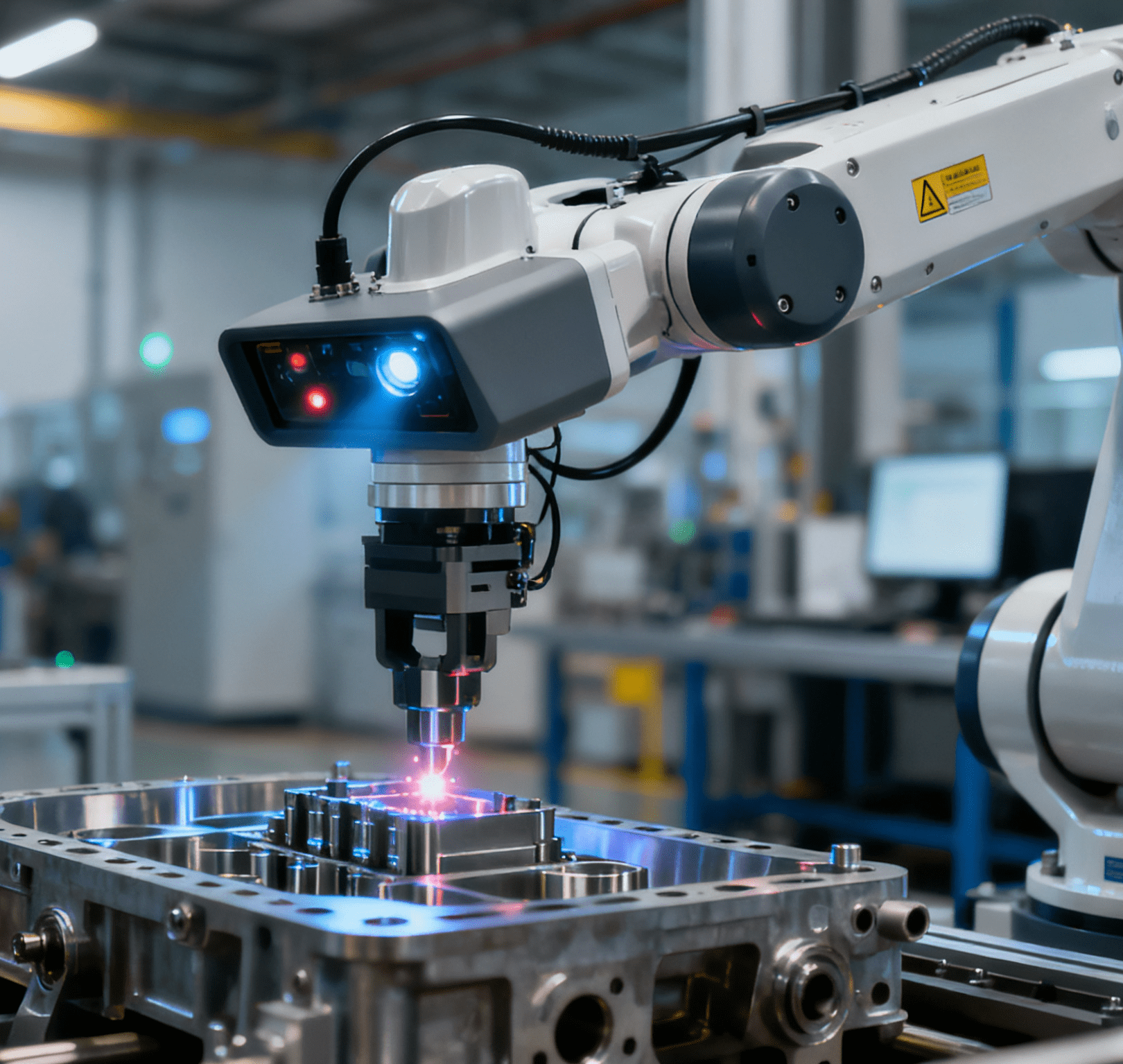

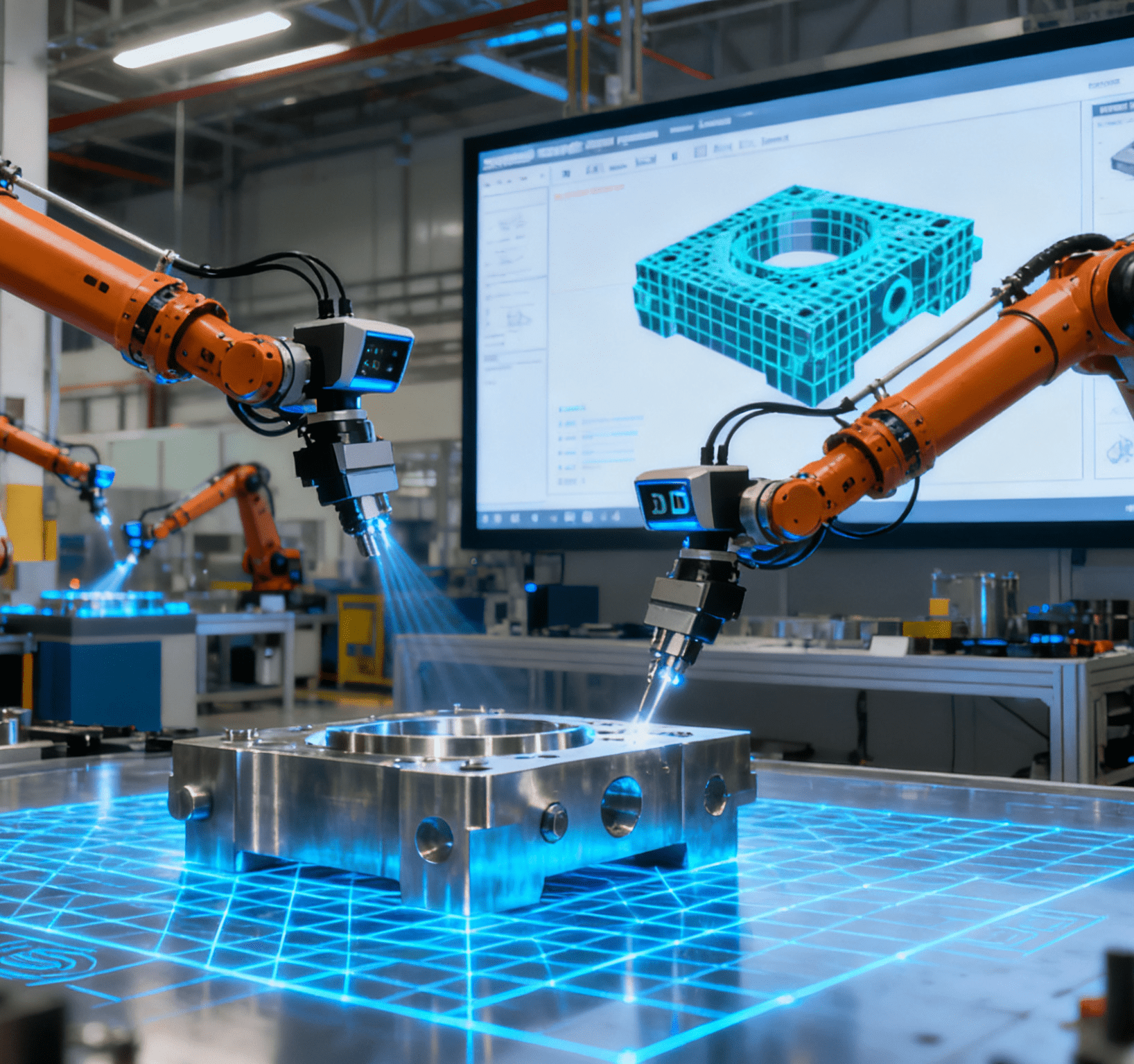

With the increasing demand for “lightweight, high-precision, and green manufacturing” in the manufacturing industry, CNC spinning is upgrading in two directions: On one hand, it is integrating with intelligent technologies. By installing visual inspection systems, real-time monitoring of the processing process is realized, reducing manual intervention. On the other hand, it is expanding the capability of processing new materials, such as optimizing the spinning process for high-strength steel, magnesium alloys, and composite materials, to further expand the application scope.

As an efficient solution in the field of metal forming, CNC spinning is not intended to “replace all processes”. Instead, by accurately matching workpiece characteristics and manufacturing requirements, it has become an indispensable part of the modern manufacturing system. Whether it is precision component enterprises or large-scale equipment manufacturers, they can evaluate the adaptability of their products to the CNC spinning process based on their own product types, so as to achieve dual improvements in production efficiency and product quality.