In the precision-oriented development of modern manufacturing, CNC precision machining has emerged as a key technical pillar in the field of medical accessory and component manufacturing, thanks to its exceptional machining accuracy and stability. As a technology-focused team specialized in precision machining, we consistently leverage our professional machining capabilities to provide high-precision and high-reliability CNC machining solutions for the medical industry. Our offerings cover core areas such as CNC machining of medical accessories and precision machining of medical components, facilitating the accurate transformation of our clients’ design concepts into high-quality products.

Technical Advantages and Core Value of CNC Precision Machining

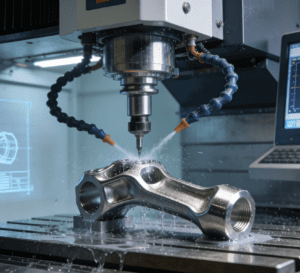

CNC precision machining is an advanced manufacturing process that achieves precise machining of various materials through computer numerical control technology. Its core advantage lies in its ability to achieve micron-level machining accuracy, ensuring that component dimensions, shapes, and surface roughness meet stringent design standards. This high-precision machining capability is particularly critical in the manufacturing of medical accessories and components—whether it is structurally complex orthopedic implants or precision miniature medical catheter assemblies, CNC precision machining technology is essential to guarantee product consistency and reliability.

Compared with traditional machining methods, CNC precision machining is characterized by high automation, stable processing efficiency, and strong repeatability. By programming and controlling the motion trajectory and machining parameters of machine tools, it can effectively reduce human operation errors and improve the stability of machining quality. Meanwhile, its flexible processing adaptability can meet the machining requirements of various materials, including metal materials such as stainless steel, titanium alloy, and aluminum alloy, as well as non-metallic materials such as engineering plastics and ceramics, providing broad space for the diversified design of medical products.

Professional Practices and Application Scenarios of CNC Machining for Medical Accessories

In the field of medical accessory manufacturing, CNC precision machining undertakes the processing of key components. Taking medical instruments as an example, high-precision accessories such as surgical knife heads, joint prosthesis components, and dental implant abutments all require CNC precision machining. Our machining process strictly complies with the quality standards of the medical industry. Every stage, from raw material pretreatment and in-process dimensional inspection to final surface treatment (such as polishing, passivation, and coating), is subject to rigorous quality control, ensuring that the biocompatibility, mechanical properties, and surface precision of the accessories meet medical application requirements.

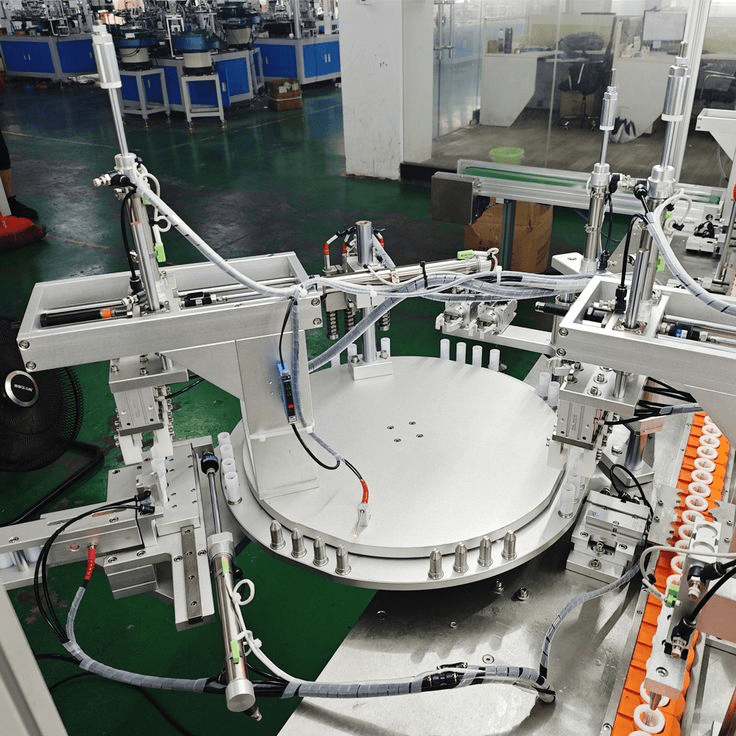

We adopt customized machining solutions for different types of medical accessories. For small-sized precision components, such as transmission gears of insulin pumps and miniature bearing assemblies of endoscopes, we utilize high-precision vertical machining centers or Swiss-type lathes to achieve precise control of millimeter-scale dimensions. For syringe production, a typical high-demand medical accessory, our CNC machining first completes the precision processing of core components such as syringe barrels and plungers, and then seamlessly connects with Syringe Automatic Assembly Equipment. This equipment realizes automated and hygienic assembly of syringe components, including needle mounting, sealing inspection and other key links, which not only ensures the assembly accuracy and consistency of syringes but also meets the strict hygiene standards of the medical industry. For large-sized components with complex structures, such as frame components of medical imaging equipment and transmission mechanisms of operating tables, we employ horizontal machining centers or 5-axis machining centers to complete multi-surface and multi-dimensional precision machining, ensuring the assembly accuracy and service performance of the accessories.

Technical Requirements and Quality Assurance for Precision Machining of Medical Components

The precision machining of medical components not only demands dimensional accuracy but also prioritizes component functionality and safety. During the machining process, we fully consider the service environment and stress conditions of the components, and avoid the impact of machining stress on component performance by rationally selecting machining processes and tool parameters. For example, for orthopedic implant components subjected to alternating loads, we adopt low-speed precision milling processes to reduce surface machining marks and improve the fatigue resistance of the components. For medical components that come into direct contact with human tissues, we strictly control surface roughness to ensure surface smoothness and minimize the risk of tissue irritation.

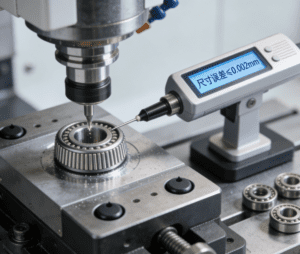

To ensure the machining quality of medical components, we have established a comprehensive inspection system. Using precision testing equipment such as coordinate measuring machines, image measuring instruments, and roughness testers, we conduct full-dimensional inspections of component dimensional accuracy, geometric tolerances, and surface quality. Every batch of machined components must undergo first-article inspection, in-process sampling inspection, and final inspection to ensure product quality traceability. Meanwhile, we actively introduce digital machining technologies, optimize machining paths through CAD/CAM software, simulate machining processes in advance, and predict potential machining errors, thereby improving component machining accuracy from the source.

Full-Process Collaboration of Precision Machining Services and Customer Value

As a professional CNC precision machining service provider, we always adhere to a customer-centric approach and have built a full-process collaboration system covering drawing analysis, process planning, machining, and delivery. Upon receiving a customer’s machining request, our technical team first conducts a detailed analysis of component drawings, and formulates optimal machining process plans based on material characteristics and application requirements. For special requirements in the medical field, such as compliance with the ISO 13485 Medical Device Quality Management System, we strictly implement relevant specifications during the machining process, ensuring the cleanliness of the machining environment and the suitability of equipment.

Through long-term industry practice, we have accumulated rich experience in the machining of medical accessories and components, and are able to provide customers with one-stop services ranging from prototype trial-manufacturing to mass production. Whether it is the machining of single-piece or small-batch R&D prototypes, or large-scale production of tens of thousands of units, we can ensure a balance between delivery cycle and machining cost through rational production capacity allocation and process optimization. We deeply understand that every detail of a medical product is related to user health and safety, so we always treat every machining task with a rigorous attitude and create value for customers with professional technical capabilities.

Empowering the Innovative Development of the Medical Industry with Precision Machining

In today’s era of continuous advancement in medical technology, CNC precision machining technology is becoming an important driving force for the innovation of medical products. We focus on the field of precision machining, and deeply cultivate the market of CNC machining for medical accessories and precision machining for medical components. With advanced equipment, professional technology, and strict quality control, we provide customers with high-quality machining services. If you need high-precision CNC machining solutions in the process of medical product manufacturing, please feel free to contact us. We will help your products gain competitive advantages in the market with enthusiastic services and exquisite technology.

By continuously improving machining technology and optimizing service processes, we are committed to becoming a reliable precision machining partner for the medical industry, jointly exploring the unlimited possibilities of precision manufacturing with customers, and contributing more to the development of the medical industry.