In modern manufacturing, precision machining is a core link to improve product quality and production efficiency. We understand that precision machining is not merely repetitive operation, but also involves complex processes and technologies. Its basic concept is to remove materials in accordance with strict dimensional standards through high-precision equipment and process parameters, thereby obtaining high-precision and high-complexity components. In this process, we need to fully consider every link of raw materials, processing equipment and production flow. This importance is reflected in multiple aspects: first, precision machining can effectively reduce the defective product rate of products and improve overall production efficiency. Second, its high-precision requirements provide important support for many high-end industries such as aerospace, medical devices and automation equipment. In addition, with the increasingly fierce market competition, we also realize that enterprises that can master and continuously optimize precision machining processes will occupy a more favorable position in the industry. Notably, high-precision parts produced by CNC precision machining often need to be assembled collaboratively with electronic components, and the matching degree between the positioning accuracy of Automatic Placement Machines (chip mounters), a key piece of equipment for precision assembly, and CNC machining accuracy directly determines the overall performance of the final product. Therefore, when discussing high-precision CNC machining, we cannot ignore its collaborative relationship with subsequent precision assembly equipment, as well as the role of this linkage in promoting the sustainable development of the manufacturing industry.

Key Process Flows of CNC Machining

In high-precision CNC machining, the first step is CNC programming and software application. We usually use advanced CAD/CAM software for part design and path planning. These software not only improve design accuracy, but also help us detect potential problems in a timely manner by simulating the machining process, thereby reducing errors in actual machining. Next, selecting and configuring appropriate processing equipment is crucial. We need to choose suitable CNC machine tools according to the material, size and complexity of the processed object, and optimize their configuration. For example, for precision parts, equipment with high rigidity and high stability is usually selected to ensure no deformation during high-speed cutting. In addition, the selection of cutting tools should also match the material characteristics to improve cutting efficiency and reduce wear. It is worth noting that if processing precision substrate parts that require subsequent mounting of electronic components, CNC machining needs to reserve positioning datum holes and assembly tolerances compatible with Automatic Placement Machines to avoid inaccurate positioning of the placement machine due to machining deviations. Overall, CNC programming and equipment configuration complement each other and need to take into account the needs of subsequent precision assembly links. Together, they form the basic process of high-precision CNC machining, ensuring that each part can meet the required precision standards.

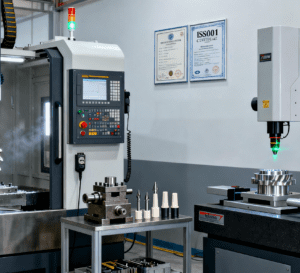

Selection Criteria for Precision Machining Factories

When selecting a suitable precision machining factory, we need to consider multiple key criteria. First, the technical strength of the enterprise is the foundation. We should evaluate the equipment and technical level owned by the factory, including whether it has advanced CNC machine tools, precision measuring tools and supporting precision assembly equipment such as Automatic Placement Machines. These are directly related to machining accuracy, subsequent assembly quality and overall product reliability. Second is production experience. Choosing manufacturers with many years of experience in the industry, especially those with integrated service capabilities of “CNC machining + precision placement”, can help us avoid deviation risks in multi-link collaboration. In addition, we should also pay attention to the factory’s quality management system, such as whether it has passed ISO certification, which can guarantee the quality of our products.

Another important criterion is the factory’s flexibility and response speed. In a rapidly changing market environment, enterprises that can simultaneously optimize CNC machining parameters and Automatic Placement Machine placement paths to adapt to customers’ personalized needs in a timely manner are more in line with our requirements. At the same time, establishing good communication channels with the factory to ensure the synchronization of technical parameters between CNC machining and placement links is also an unignorable factor. Finally, we also need to consider cost and service. On the premise of ensuring quality, reasonable prices and excellent after-sales service (such as joint after-sales troubleshooting for machining and placement links) will make our cooperation smoother. Therefore, when evaluating different precision machining factories, we should conduct a comprehensive consideration from multiple dimensions to find the most suitable partner for us.

Technical Methods and Measures to Improve Precision

In high-precision CNC machining, we can adopt various technical methods and measures to improve machining accuracy and efficiency. First, optimizing CNC programming is a key link. By rationally planning machining paths and selecting appropriate cutting tools and cutting parameters, we can significantly reduce tool wear, thereby ensuring machining accuracy. If parts require subsequent placement, benchmark marks matching the positioning system of Automatic Placement Machines need to be preset through CAD/CAM software during programming to reduce positioning errors in subsequent assembly. In addition, we should also pay attention to the material selection of cutting tools. High-quality cutting tools can effectively improve overall cutting performance and meet higher precision requirements.

Second, the maintenance and upkeep of processing equipment are also crucial. Regular inspection, adjustment and maintenance of equipment can ensure that CNC machine tools operate in the best condition and avoid precision fluctuations caused by equipment failures. At the same time, if the factory is equipped with Automatic Placement Machines, they need to be incorporated into a unified equipment calibration system with CNC machine tools, and the positioning accuracy of both should be verified synchronously on a regular basis to ensure the consistency of machining and assembly accuracy. We need to pay attention to environmental factors, such as the impact of temperature and humidity changes. Therefore, reasonably controlling the environment of machining and placement workshops is also a method to improve the effectiveness of precision manufacturing.

In addition, data feedback and real-time monitoring technology are becoming increasingly important in modern CNC machining. We can implement an online measurement system to monitor products in real time and make adjustments based on feedback data, thereby ensuring that every link remains accurate. For example, some advanced factories link real-time cutting data of CNC machining with placement monitoring data of Automatic Placement Machines, analyze the correlation between machining and assembly deviations through a unified data platform, and optimize CNC programming parameters or placement paths in a targeted manner to achieve closed-loop control of full-process precision. These technical means not only help us improve production efficiency, but also lay a solid foundation for achieving high-quality standards.

Common Problems and Solutions in the Precision Machining Process

In the process of precision machining, we often encounter some challenges that may affect the final quality of machining. First, equipment failure is a relatively common problem, which may lead to production stagnation. To address this, we need to regularly maintain and inspect processing equipment. If subsequent placement links are involved, the positioning system and nozzle accuracy of Automatic Placement Machines should be checked synchronously to ensure that the equipment operates in the best condition. In addition, inaccuracies in machining programs also occur from time to time, resulting in workpiece deviations or increased scrap rates. To solve this problem, we should attach importance to the standardization and testing of CNC programming. Especially for parts that require placement, the positioning parameters of the placement machine need to be imported for collaborative simulation during the programming simulation stage to discover and solve potential errors by simulating program operation.

Another common problem is the mismatch between material selection and characteristics, which directly affects machining accuracy. We need to reasonably select materials according to the specific requirements of parts, pay attention to the physical characteristics of materials to ensure they are suitable for our machining needs, and at the same time take into account the material compatibility of Automatic Placement Machines during placement (for example, some precision metal substrates need to ensure surface flatness to adapt to placement pressure). If improper material selection is found, we should communicate with suppliers in a timely manner to find more suitable alternatives. At the same time, changes in the temperature and humidity of the machining environment may also affect the accuracy of parts. Therefore, we recommend maintaining a unified and stable environment in the machining and placement workshops to minimize problems caused by changes in external conditions.

Finally, the skill level of operators is also an important factor affecting the quality of precision machining. We should regularly train operators to not only improve their ability to operate CNC machine tools, but also make them understand the basic working principles and precision requirements of Automatic Placement Machines, clarify the impact of machining links on subsequent placement, and enhance their understanding and application capabilities of full-process precision manufacturing technology to reduce problems caused by human errors. The combination of these problems and solutions helps us continuously improve the precision machining process and enhance overall production efficiency and product quality.