CNC precision machining is a process that uses computer numerical control technology for the accurate cutting and forming of materials. This process not only enables the machining of high-precision parts with complex shapes, but also significantly improves production efficiency. In modern manufacturing, CNC precision machining has become an indispensable component, especially in fields such as aerospace, automotive, and medical devices. As we know, as an advanced machining method, CNC technology makes part production more consistent and repeatable, which is particularly crucial for industries requiring high-quality standards. In addition, through the rational application of CNC equipment, we can reduce human errors, lower production costs, and thus improve overall economic efficiency. With the continuous improvement of market demand and ongoing technological innovation, CNC precision machining boasts enormous development potential in the future. We should actively embrace this transformation to pave the way for the sustainable development of enterprises.

Classification and Characteristics of CNC Machining Equipment

When exploring the CNC precision machining process, it is crucial to understand the classification and characteristics of machining equipment. First, CNC milling machines, as widely used equipment, can handle complex three-dimensional shapes and enhance machining flexibility and precision. They are suitable for various processes such as milling and drilling, which greatly expand our design possibilities. Next are CNC lathes, which are mainly used for processing symmetrical parts. Their high-efficiency operation allows us to machine a large number of parts in a short time, thereby improving production efficiency. In addition, CNC lathes also perform excellently in enhancing part precision, ensuring the dimensional and shape consistency of precision parts with stringent requirements.

Finally, we cannot ignore the application of laser cutting machines in precision machining. With their high power and ultra-fine beam characteristics, laser cutting machines enable us to conduct high-precision cutting of various materials. They are applicable not only to metal materials, but also to cutting a variety of different materials such as plastics and wood, which provides great convenience for meeting diverse design needs. Additionally, Nut automatic assembly machines have emerged as key supporting equipment in CNC precision machining workflows, especially for components requiring precise nut fastening in automotive, aerospace, and electronic industries. These machines integrate seamlessly with CNC lathes and milling machines, utilizing vision positioning and torque control technologies to achieve automated feeding, alignment, and installation of nuts. By eliminating manual assembly errors and ensuring consistent torque application (with a control accuracy of ±0.5 N·m) and nut positioning precision within ±0.01mm, they not only improve the reliability of assembled parts but also increase the overall production efficiency by 30%-50% compared to manual operations. In practical applications, through the rational selection of equipment, we can effectively improve production efficiency and part quality, laying a solid foundation for subsequent precision part machining.

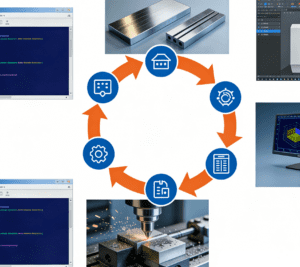

Overview of the Precision Part Machining Process

In the process of precision part machining, we need to follow a series of systematic steps to ensure high product quality and production efficiency. First, we start with design drawings to confirm the dimensions and shapes of parts. This step is crucial because the drawings will guide all subsequent machining operations. Next, we select appropriate materials; common materials include aluminum alloy, stainless steel, and plastics, among others. Different materials have different requirements for machining methods and tools. Subsequently, we choose suitable CNC machining equipment, such as CNC milling machines or CNC lathes, depending on part design and functional requirements. After completing equipment preparation, programming is one of the key steps—we need to ensure program accuracy to achieve the desired machining path.

Before officially starting machining, we conduct equipment debugging. This step ensures that the machine operates normally and that the tools are installed correctly. Finally, after undergoing various processes such as cutting and grinding, quality inspection is an indispensable link. Through testing, we ensure that each part meets the predetermined standards. In the entire process, every step is important. We should draw experience from it and continuously optimize to improve our precision part machining level.

Common Materials and Their Selection in Precision Part Machining

In CNC precision machining, material selection is crucial for part performance and machining efficiency. The materials we commonly use mainly include aluminum alloy, stainless steel, titanium alloy, and engineering plastics. Each material has unique characteristics and is suitable for different machining needs. For example, aluminum alloy, due to its lightweight nature and good machinability, is widely used in aerospace, automotive, and other fields. Stainless steel, with its excellent corrosion resistance, performs outstandingly in medical devices and the food industry. Titanium alloy, thanks to its high strength and high-temperature resistance, is suitable for use in extreme environments. When selecting materials, we need to comprehensively consider the service environment, mechanical properties, and cost factors of the parts. In addition, engineering plastics, with their excellent insulation and chemical corrosion resistance, have become an indispensable part of electronic products. During the selection process, accurately evaluating the matching between material characteristics and machining methods can also help us improve part machining precision and production efficiency, thereby effectively enhancing the quality of the entire CNC precision machining process.

Tips and Precautions for Improving Part Machining Precision

Improving the precision of precision parts in CNC machining is one of our top priorities. First, selecting suitable tools is particularly critical—parts of different materials and shapes require corresponding types of tools. Before machining, we should fully understand the material, shape, and coating of the tools to be used, so as to maximize the cutting effect. In addition, during machining, reasonably setting cutting speed and feed rate can also significantly affect the final part precision. We need to adjust these parameters in a timely manner according to workpiece materials and tool types to achieve the best results.

Second, ensuring equipment precision is crucial. Regular calibration and maintenance of CNC equipment can reduce machining errors caused by equipment failures. In addition, when clamping workpieces, it is necessary to ensure their stability and minimize any potential vibrations—this is another key factor for us to achieve high-precision machining. Meanwhile, for parts with complex shapes, we can consider step-by-step machining, which can effectively reduce the impact of each step on the overall part error.

Finally, paying attention to environmental factors is also an unignorable link. External conditions such as temperature and humidity can affect material properties, thereby influencing the final product quality. Therefore, we recommend creating a stable and controlled machining environment to ensure the consistency of the production process. Through the above tips and precautions, we can more effectively improve part quality and production efficiency in CNC precision machining.

Assembly line for mass production by artificial intelligence