In the field of CNC machining, process route planning is a key link to ensure machining quality and efficiency. Whether to follow traditional methods or boldly attempt innovations in CNC machining process route planning has long been a hotly debated topic in the industry. CNC machining (Computer Numerical Control Machining), especially CNC precision machining and precision part machining, imposes extremely high requirements on the scientificity and rationality of process routes.

Traditional CNC Machining Process Routes: Maturity and Stability Rooted in Long-Term Practice

Traditional CNC machining process route planning has been verified by long-term practices and is characterized by maturity and stability. It is based on existing machining experience and fixed processing procedures, with clear operating specifications. For example, in precision part machining, the traditional process route follows a set cutting sequence: rough machining first to remove most of the material allowance, followed by semi-finishing and finishing, so as to gradually achieve the dimensional accuracy and surface quality specified in the design. This approach has the advantage of low risk and is easy for operators to master after training. For machining parts with simple structures and relatively low precision requirements, it can complete tasks efficiently and stably. Moreover, the machining parameters, tool selection and other aspects of traditional process routes are well-documented, resulting in low uncertainty during the machining process and effectively ensuring the consistency of product quality.

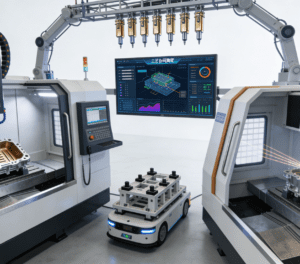

Innovative Process Route Planning: Technological Empowerment for Efficiency and Precision

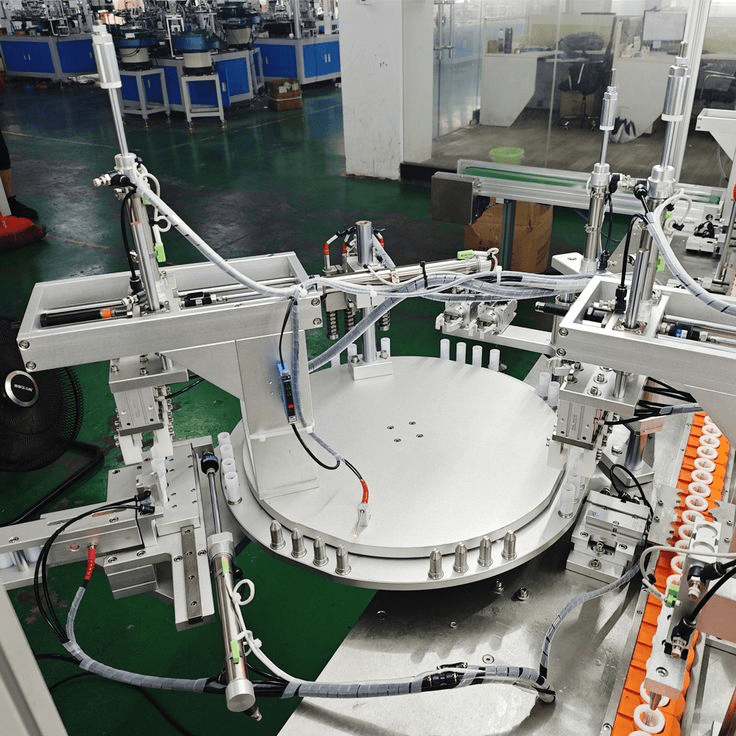

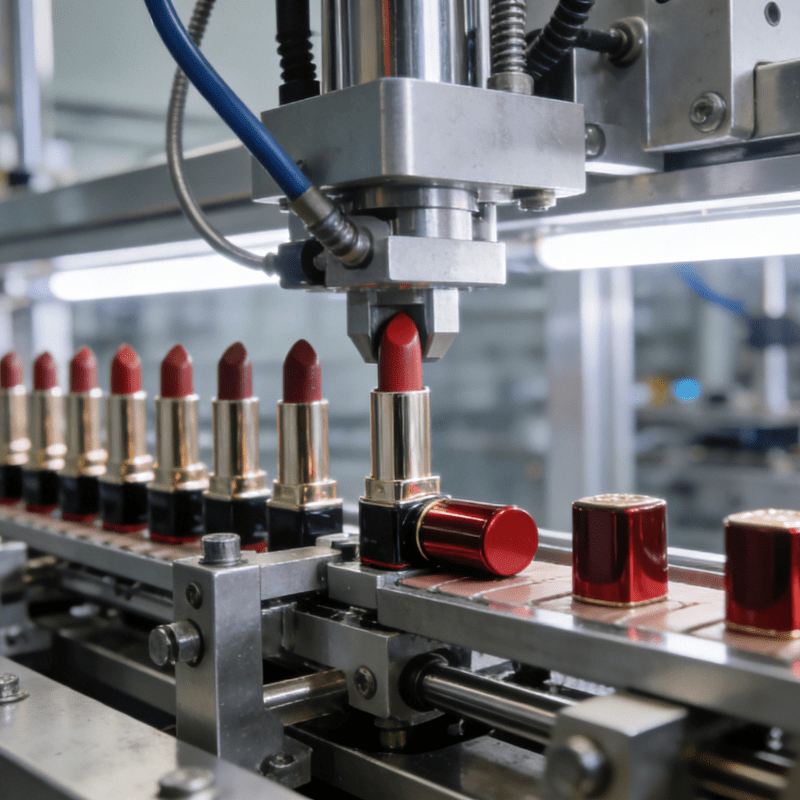

However, with the development of the manufacturing industry, innovative CNC machining process route planning has gradually emerged. Innovative process route planning often relies on advanced computer simulation technologies and data analysis methods. By simulating the machining process through software, potential problems can be identified in advance and the machining path can be optimized. In CNC precision machining, innovative process routes can adopt more flexible tool paths and cutting strategies according to the complex shapes of parts, thereby reducing machining time and improving machining accuracy. For instance, for precision parts with complex curved surfaces, traditional process routes may require multiple clamping operations and multiple processes, while innovative process routes can realize multi-surface machining in a single clamping by adopting advanced technologies such as 5-axis linkage machining. This not only improves machining efficiency but also reduces errors caused by repeated clamping. For precision components like nebulizer cores which have strict dimensional requirements and complex internal structures, innovative CNC process routes first complete high-precision machining of core parts through simulated-optimized tool paths, and then seamlessly connect with Nebulizer Assembly Machine. This integration realizes the continuous operation of precision machining and automated assembly, further compressing the production cycle and ensuring the consistency of nebulizer product performance, which is a typical manifestation of innovative process routes empowering precision medical component manufacturing.

Balancing Tradition and Innovation: Practical Selection Based on Comprehensive Factors

In practical applications, choosing between adhering to tradition and embracing innovation requires comprehensive consideration of multiple factors. For CNC machining with large production batches and relatively fixed part structures, traditional process route planning can guarantee production continuity and efficiency by virtue of its stability and low-cost advantages. However, for new product R&D, small-batch production, and precision part machining with extremely high requirements for accuracy and efficiency, innovative process route planning is more advantageous. It can quickly respond to design changes, meet personalized machining needs, and enhance product competitiveness.

In CNC machining process route planning, adhering to tradition and pursuing innovation are not mutually exclusive. Traditional process route planning is the foundation of industry development, providing experience and reference for innovation; while innovation is the driving force for industry progress, bringing new ideas and methods to CNC machining. In practical operations, we should reasonably select and apply traditional and innovative process route planning methods based on specific machining requirements, part characteristics, production scales and enterprise technical capabilities, so as to achieve the optimal balance among quality, efficiency and cost in CNC machining and promote the sustainable development of the CNC machining industry.