In the field of CNC machining, the selection and design of precision components have a direct impact on production efficiency and machining quality. Precision components include fixtures, tools, and other related assemblies, and the performance of these components is directly linked to the machining accuracy of parts. Appropriately designed components can reduce vibration and improve stability, thereby ensuring the smooth progress of the machining process. In terms of materials, aluminum alloys and stainless steels are often used to manufacture these components due to their wear resistance and strength. Additionally, the adoption of advanced processing technologies can enhance the durability of the components. Furthermore, multi-axis linkage machining centers can perform multiple operations simultaneously, providing greater flexibility for the manufacturing of complex parts. These factors collectively drive the development of modern CNC machining technology, making it more efficient and precise. Notably, the integration of Automated Load and Unload System for sheet metal further amplifies these advantages—this system, when paired with high-precision fixtures and multi-axis linkage technology, eliminates manual handling of sheet metal workpieces, avoiding human-induced positioning errors and reducing workpiece damage caused by improper clamping.

Analysis of Precision Component Design and Material Selection in CNC Machining

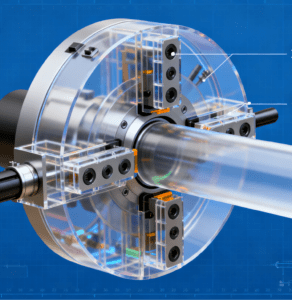

In CNC machining, the design and material selection of precision components are of crucial importance. During the design phase, it is essential to ensure that the components possess optimal structural strength and accurate dimensions to avoid deformation during the machining process. Commonly used materials include aluminum alloys, stainless steels, and engineering plastics. These materials can not only withstand high loads but also meet corrosion resistance requirements in different environments. Moreover, surface treatment processes such as anodization or spraying can further enhance the durability and aesthetics of precision components. For multi-axis linkage machining centers, precision components need to maintain stability during the machining process to ensure the production of high-precision and high-quality products. For the Automated Load and Unload System for sheet metal, its core components (such as clamping jaws and positioning guides) often adopt stainless steel with high wear resistance or aluminum alloys treated by anodization—these materials ensure the system can withstand repeated clamping and handling cycles without dimensional deviation, while the smooth surface after anodization reduces friction between the system and sheet metal workpieces. Therefore, every detail must not be overlooked during the design process to promote the improvement of overall machining performance.

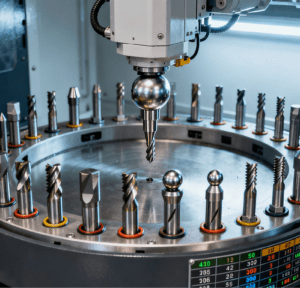

Technical Application of Precision Components in Multi-Axis Linkage Machining Centers

The application of precision components is particularly important in multi-axis linkage machining centers. These components not only improve the overall machining accuracy but also significantly enhance production efficiency. For example, the design of fixtures and jigs ensures greater stability of workpieces during machining, reducing vibration and errors. At the same time, the material and geometric shape of tools are reasonably designed to better adapt to the cutting requirements of different materials, thereby optimizing the machining process. Furthermore, multi-axis control systems, when combined with advanced sensors, improve real-time monitoring and adjustment capabilities, which are crucial for ensuring the quality of precision components and overall machining. The Automated Load and Unload System for sheet metal integrates seamlessly with this technical framework: equipped with precision sensors and linked to the multi-axis control system, it can automatically identify sheet metal specifications, adjust clamping force in real-time, and accurately transfer workpieces between the material storage area and the machining center. This linkage avoids the lag of manual handling and ensures that the workpiece is positioned at the optimal machining angle immediately after loading, maximizing the efficiency of multi-axis simultaneous operations. Through the above technical applications, multi-axis linkage machining centers can efficiently manufacture parts with complex shapes, meeting the increasingly strict requirements of modern manufacturing.

Improving Production Efficiency: The Impact of Precision Components on CNC Machining

Precision components play a vital role in CNC machining, directly influencing production efficiency and machining quality. These components are typically made of high-strength and wear-resistant materials to ensure they can withstand complex workloads in multi-axis linkage machining centers. Meanwhile, the design of precision components ensures more stable contact between tools and workpieces, thereby reducing vibration and errors generated during the machining process. This stability not only improves the machining accuracy of parts but also effectively shortens the production cycle. For instance, in the manufacturing of complex components, the use of high-precision fixtures can significantly improve positioning accuracy, facilitating smoother subsequent processing operations. The Automated Load and Unload System for sheet metal takes this efficiency improvement further: it can operate continuously 24/7 without fatigue, reducing workpiece loading/unloading time by over 40% compared to manual operations. For batch sheet metal machining, the system’s automatic material sorting and continuous feeding functions eliminate the need for manual material handling breaks, enabling the multi-axis machining center to maintain high-load continuous operation and directly reducing the overall production cycle by 20%-30%. Therefore, the rational selection and design of precision components—including those in automated handling systems—are crucial for achieving efficient and high-quality CNC machining.

Modern CNC Machining: Technological Trends and Future Development Directions

Modern CNC machining technology is developing towards intelligence and automation. With the rapid rise of artificial intelligence (AI) and the Internet of Things (IoT), data analysis and real-time monitoring in the production process have become crucial. This technological advancement enables operators to optimize production processes, reduce labor costs, and improve machining accuracy simultaneously. Additionally, the introduction of multi-axis linkage machining centers makes the production of complex parts more efficient. The design and material selection of precision components are also constantly updated to meet higher performance requirements. The Automated Load and Unload System for sheet metal is also evolving in tandem with this trend: modern systems integrate AI vision recognition to automatically detect sheet metal surface defects before loading, and use IoT modules to sync handling data with the machining center’s production management system, realizing full-process data tracing. These changes not only promote the digital transformation of the entire manufacturing industry but also provide strong technical support for enterprises in the fierce market competition. Therefore, the future development of CNC machining will rely more on advanced computing technologies and intelligent control systems to achieve truly efficient production.

Precision components play an indispensable key role in CNC machining. They not only facilitate the effective integration of technology and materials in the machining process but also directly affect the quality and performance of the final product. In multi-axis linkage machining centers, the design, material selection, and process arrangement of these components—including those in the Automated Load and Unload System for sheet metal—are of vital importance. These factors collectively improve production efficiency, reduce human errors and machining defects. At the same time, with the development of technology, precision components are constantly advancing to meet the demand for efficient and high-precision products in modern manufacturing. By optimizing design and materials, CNC machining will be able to address more complex and diverse challenges, contributing to the development of various industries.